Conveyer belt dynamic mechanical property testing device

A technology of dynamic mechanics and testing equipment, which is applied in the direction of measuring equipment, testing of mechanical components, testing material strength by applying stable tension/pressure, etc. It can solve the problems of inability to correctly characterize the dynamic mechanical properties of conveyor belts, cracks, broken belts, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

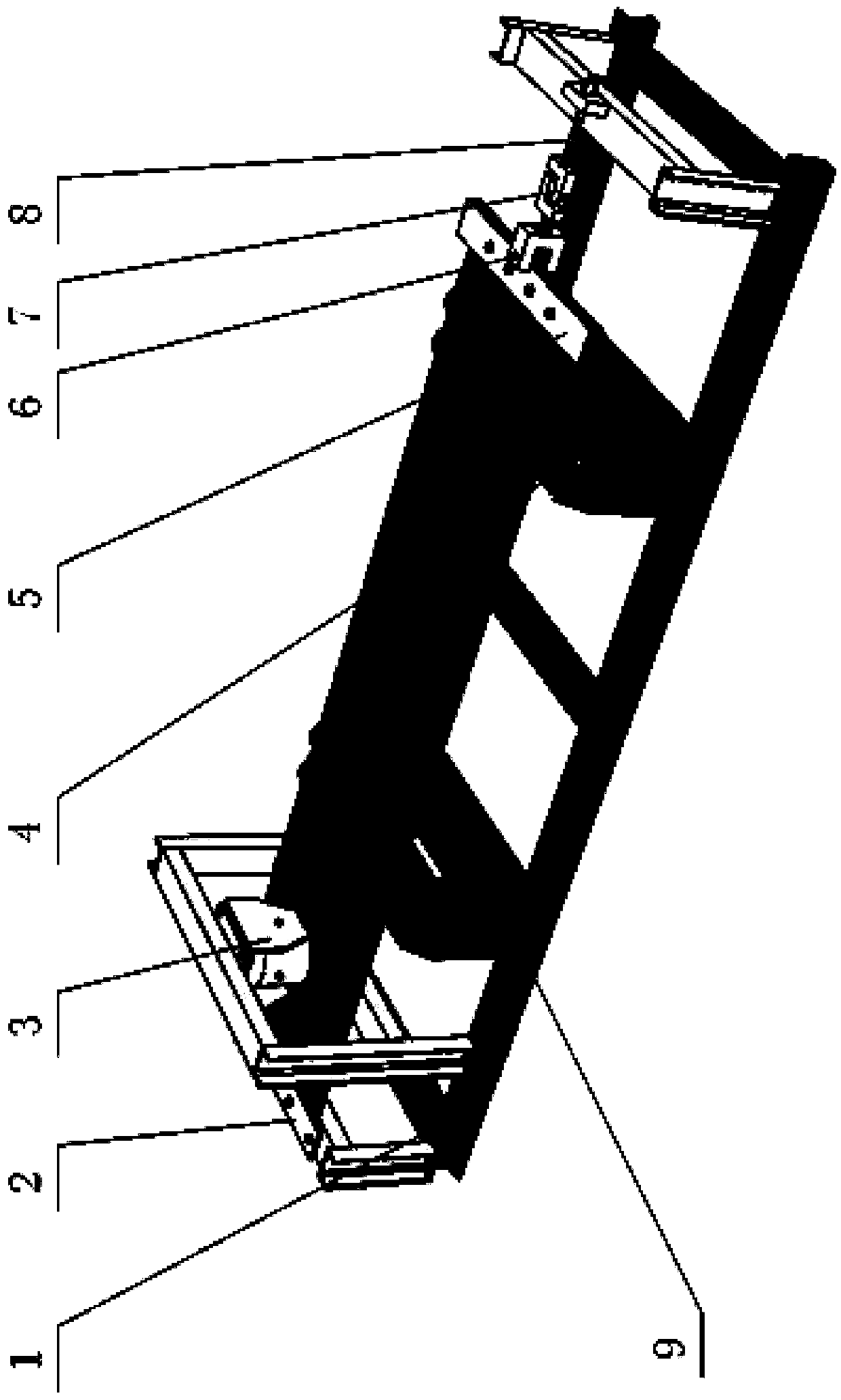

[0017] Such as figure 1 As shown, the conveyor belt dynamic mechanical performance testing device includes a conveyor belt sample support part, a load application part and an electric control part.

[0018] The conveyor belt sample support part includes a support chassis 1, a conveyor belt sample front clamping part 2, an idler roller assembly 4 and a conveyor belt sample rear clamping part 5; the conveyor belt sample front clamping part 2 includes The front upper clamping plate and the front lower clamping plate are connected up and down, and the front lower clamping plate is fixed and erected on the front end of the support chassis 1 through the front clamping component support frame; the idler assembly 4 is arranged in front of the conveyor belt sample Behind the clamping part 2, the idler assembly 4 includes an idler and an idler frame. The height dimension is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com