Mechanical testing device for breaking rock by coupling dynamic and static loads with fissure pressure and method thereof

A test device and technology of rock mechanics, applied in the field of mine rock mechanics, can solve problems such as single research and observation methods, and failure to monitor the crack development process, and achieve the effects of stable and reliable pressure, simple test process, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

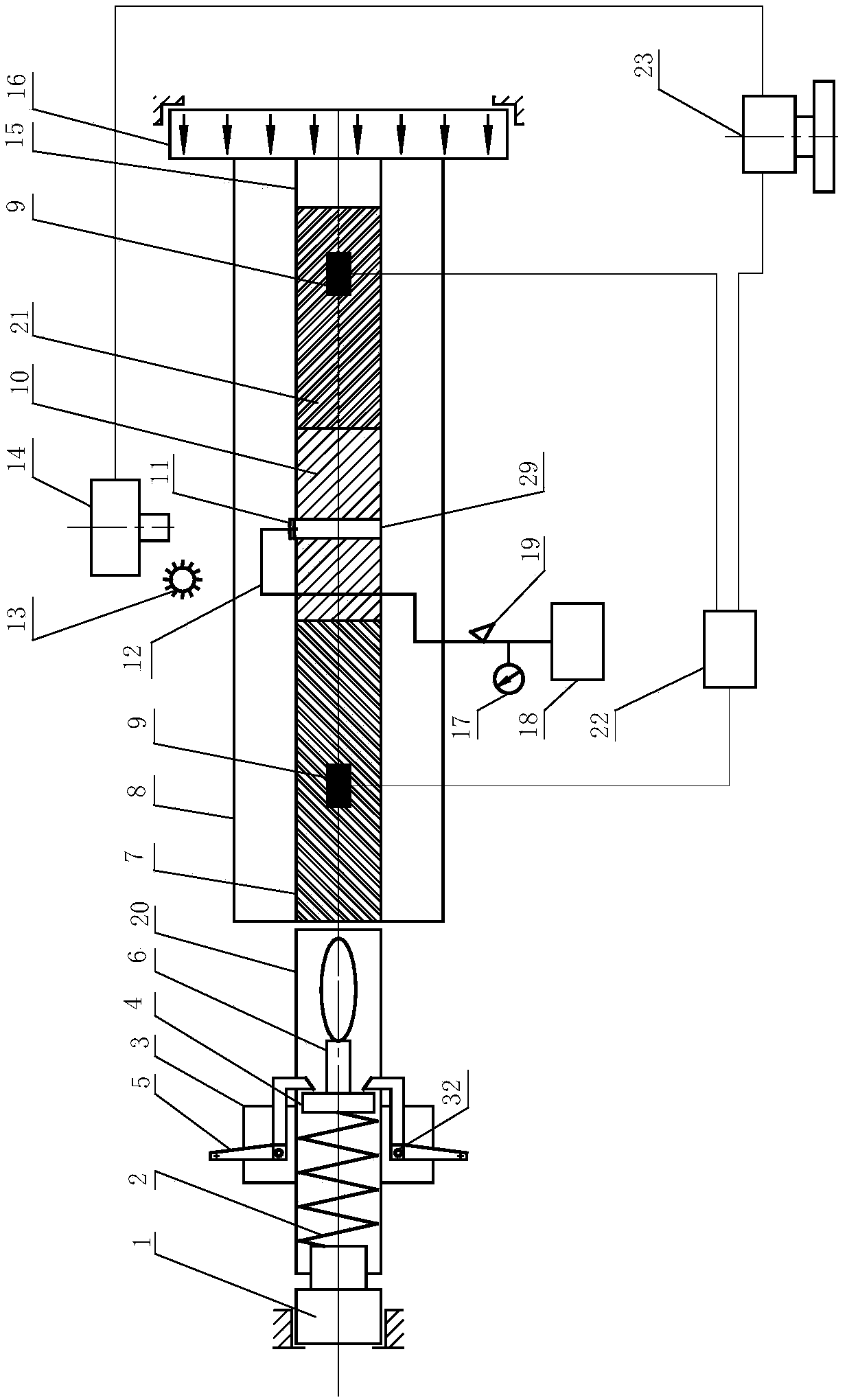

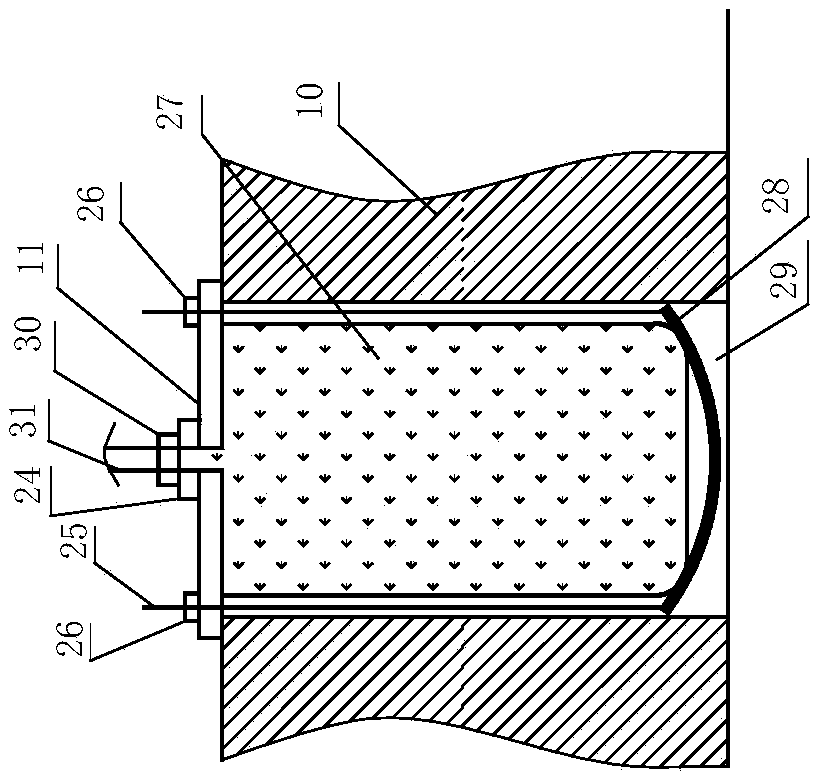

[0025] Such as figure 1 As shown, the dynamic and static load and fracture pressure coupling fracture rock mechanics test device of the present invention includes: a dynamic load loading device, a static load loading device, a test piece 10, an incident rod 7, a transmission rod 21, a data acquisition device 22, and a data processing device 23 , connecting frame 8, hydraulic pump 18, limit plate 11, high-speed microscopic camera 14, crack pressure loading head 31, steel wire 25, compensating light source 13 and pressurized air bag 27, test piece 10 is housed on connecting frame 8, in test The two ends of the piece 10 are equipped with the incident rod 7 and the transmission rod 21 respectively, the test piece 10, the incident rod 7 and the transmission rod 21 are on the same straight line, the dynamic load loading device loads the incident rod 7, and the static load lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com