Electromagnetic induction device and method for quantitatively characterizing degree of corrosion of steel bar in concrete

A technology for steel bar corrosion and quantitative characterization, which is applied to measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further understand the content, features and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows with accompanying drawings:

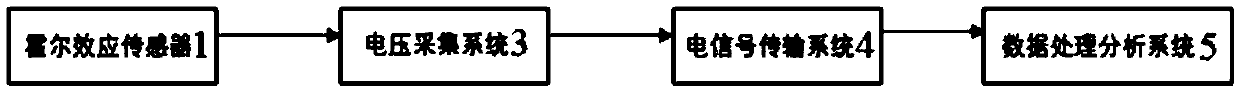

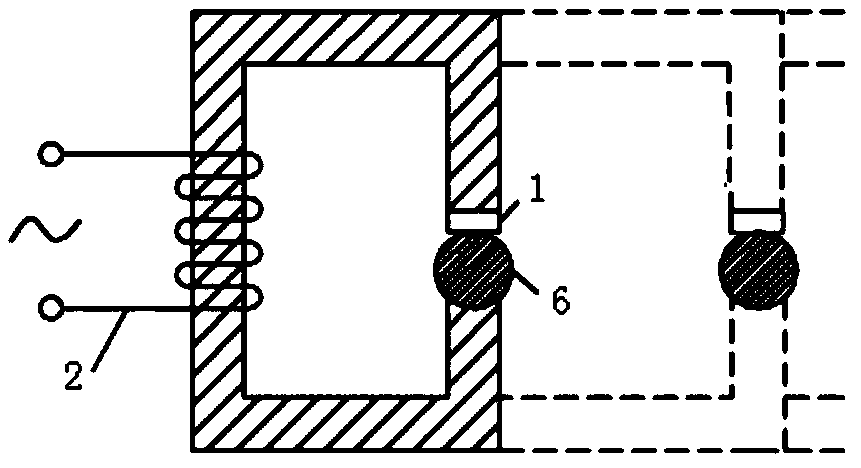

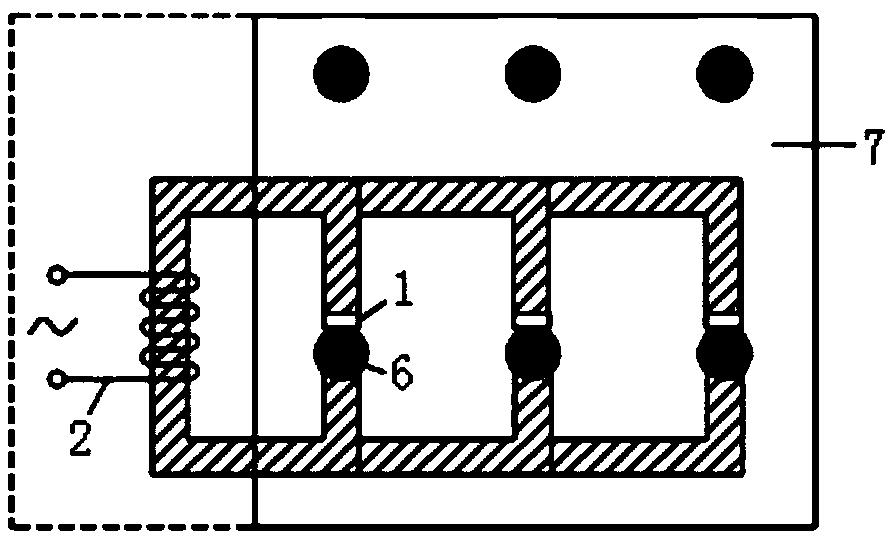

[0038] As attached figure 1 As shown, an electromagnetic induction device for quantitatively characterizing the corrosion degree of steel bars in concrete includes a Hall effect sensor 1, an AC power source 2, a voltage acquisition system 3, a signal transmission system 4, and a data analysis system 5.

[0039] The AC power supply 2 is connected to the spiral coil, and the to-be-detected part of the steel bar 6 in the reinforced concrete member 7 is placed in the spiral-coil, so that a magnetic field is generated around the to-be-detected part of the steel bar 6.

[0040] The Hall-effect sensor 1 is pasted on the surface of the part to be detected of the steel bar 6 for converting the change of the magnetic field caused by the corrosion of the steel bar 6 into the change...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com