A Steady State Solute Concentration Distribution Model for Continuous Countercurrent Two-Phase Mass Transfer Process

A mass transfer process and concentration distribution technology, applied in the chemical industry, can solve problems such as small amount of calculation, difficulty in realization, and high calculation difficulty, and achieve good practicability, low difficulty in writing, and accurate calculation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

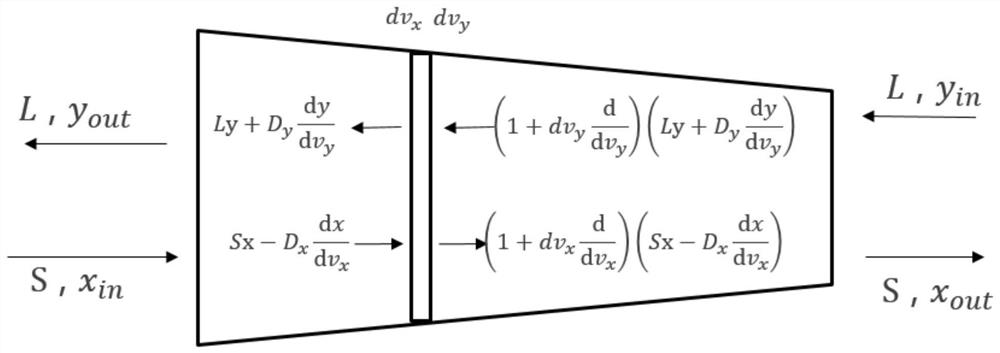

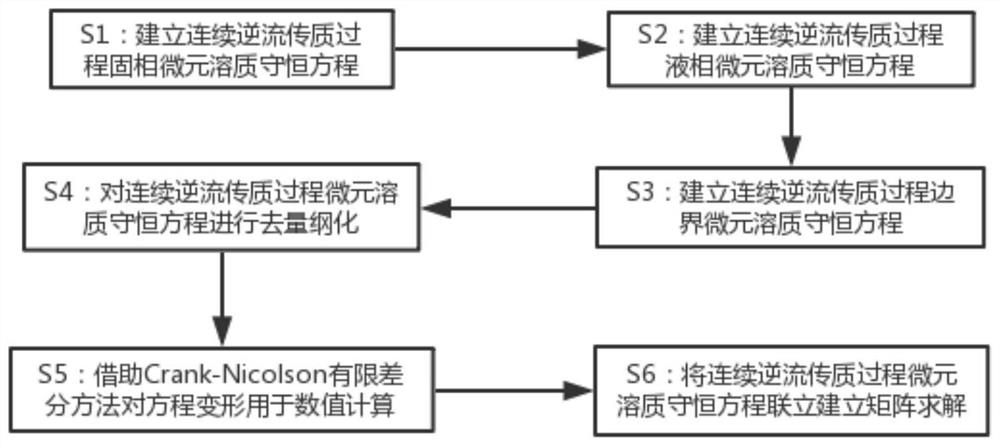

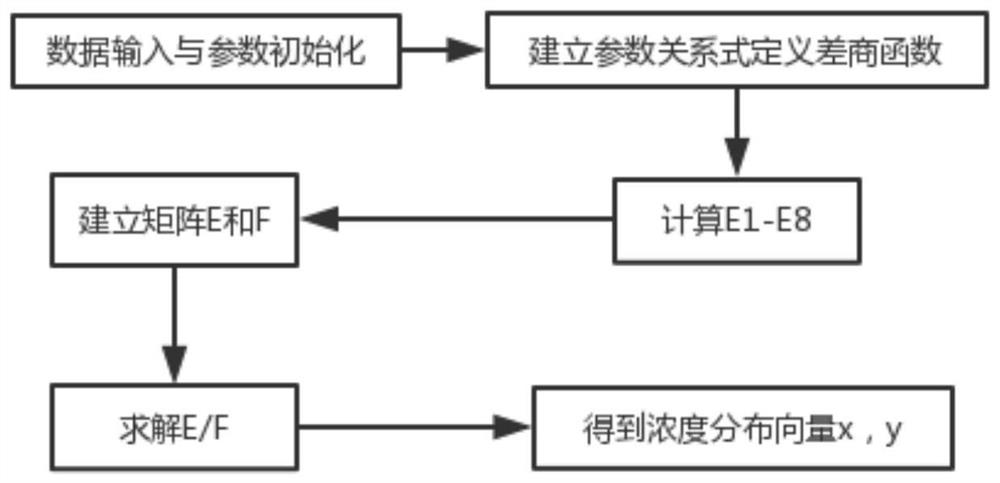

Method used

Image

Examples

Embodiment

[0090] The steady-state solute concentration distribution model of the continuous countercurrent two-phase mass transfer process in step S6 is calculated using computer software as a calculation tool. This embodiment provides a method to adjust the working parameters of the equipment for continuous countercurrent extraction of astragalus polysaccharides using water as a solvent under actual working conditions. , to realize the method of quantitatively improving the mass transfer effect.

[0091] The working parameters of the continuous countercurrent extraction process are as follows:

[0092] Astragalus raw material initial concentration: x in =97.4mg / g,,

[0093] Solvent initial concentration: y in = 0 mg / g,,

[0094] Astragalus residue concentration: x out = 56.9 mg / g,

[0095] Final concentration of extract: y out =2.71mg / ml≈2.63mg / g,

[0096] Extraction period: t=50min,

[0097] Screw speed: s=0.6r / min,

[0098] Solid-to-liquid ratio: α=1:10,

[0099] Solid phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com