Cycle stirring reactor for chemical product manufacturing

A technology of circulating stirring and chemical products, applied in chemical/physical/physical chemical fixed reactors, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as accelerating reaction rate and stratification, and achieve accelerated reaction rate , prevent the precipitation of unity, and fully respond to the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

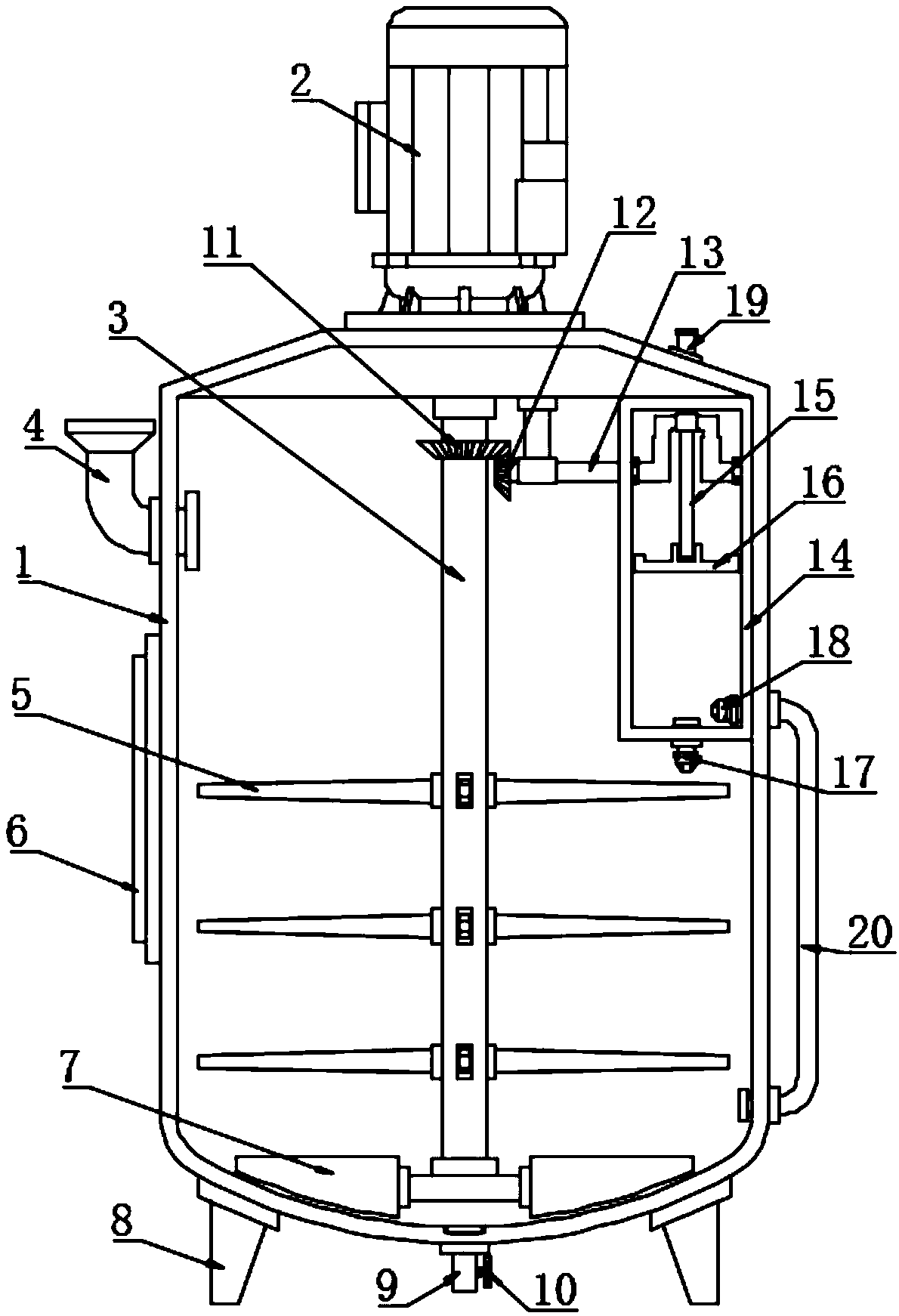

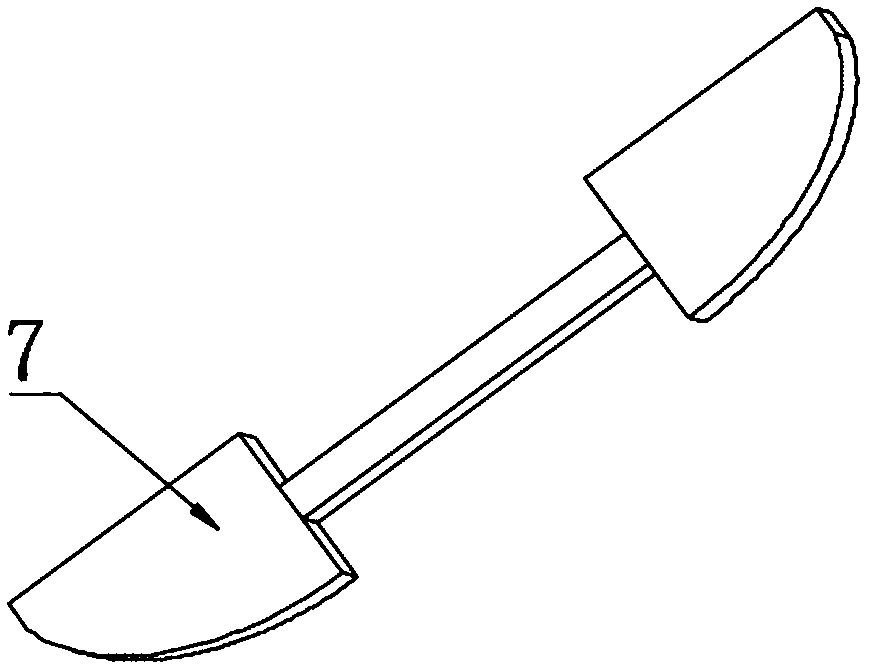

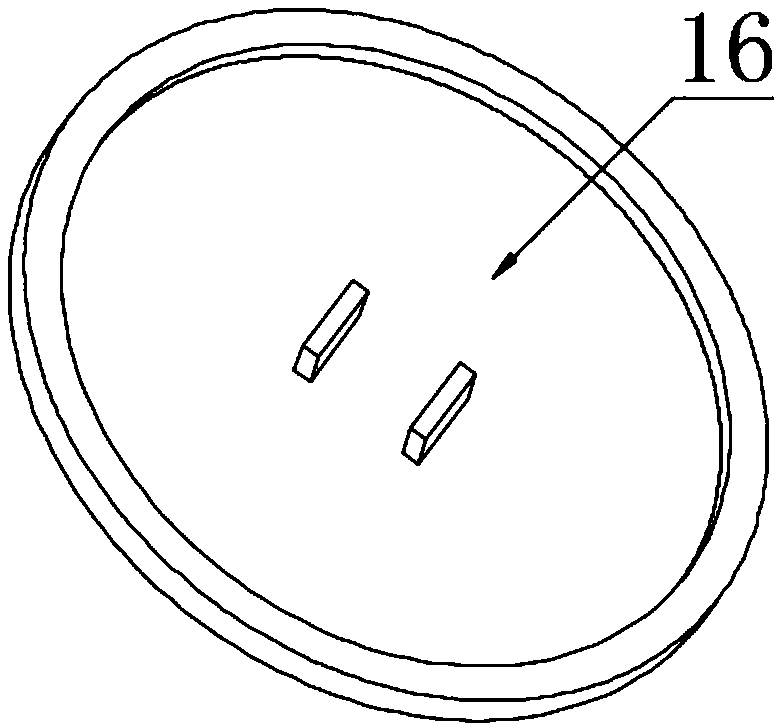

[0020] see Figure 1~3 , in the embodiment of the present invention, a kind of circulating stirring reactor for chemical product manufacturing, comprises reactor housing 1, driving motor 3, scraper 7, discharge pipe 9, circulation chamber 14 and return pipe 20; Said reactor housing The upper end of 1 is fixedly installed on the drive motor 2. Specifically, the lower part of the drive motor 2 is fixedly connected to the upper end of the reactor shell 1 through flange bolts, the lower part of the drive motor 2 is connected to the stirring shaft 3 by rotation, and the lead wire of the drive motor 2 is connected to the power supply and the switch. The actuating switch makes the drive motor 2 energized to drive the stirring shaft 3 to rotate; A scraper 7 is fixedly connected, wherein, the bottom of the scraper 7 has the same profile as the bottom of the reactor shell 1, and a control panel 6 is fixed on the side wall of the reactor shell 1, and the signal of the control panel 6 is ...

Embodiment 2

[0023] In order to make the technical solutions in this application more detailed and complete, now some supplements and explanations are made on the basis of the above-mentioned embodiment 1, so that the disclosure of the technical means adopted in this application is more sufficient, specifically, the supplements and explanations Part of the technical feature is that the control panel 6 has a central processing unit, a display screen and a control area, wherein the display screen signal is connected to the central processing unit and the drive motor 2, and the control area is provided with indicator lights and switch buttons, switch buttons and indications. The lamps are electrically connected to the power supply and the central processing unit respectively, and are operated through the display screen in the control panel 6 and transmitted to the central processing unit, so that the operation command is changed into a digital signal and sent to the drive motor 2 to realize the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com