Zinc sulfide quantum dot coated titanium dioxide air purification material and preparation method

An air purification material, titanium dioxide technology, applied in the field of air purification, can solve the problems of narrow light absorption frequency band, low luminous efficiency of quantum dots, affecting development and application, etc., and achieve the effect of uniform size, high luminous efficiency and photochemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

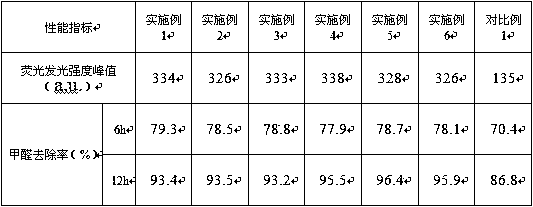

Examples

Embodiment 1

[0030] (1) Add nano-titanium dioxide, activated carbon, and diatomaceous earth into polyethylene glycol, disperse evenly, and then perform high-pressure homogeneous heating to obtain an electrospinning liquid; during high-pressure homogeneous heating, the pressure is 880MPa, and the temperature is 108 ℃, the time is 35min;

[0031] Wherein: 17 parts by weight of nano-titanium dioxide, 9 parts by weight of activated carbon, 9 parts by weight of diatomaceous earth, and 65 parts by weight of polyethylene glycol;

[0032] (2) The electrospinning solution prepared in step (1) is subjected to an electrospinning process to make a titanium dioxide composite fiber;

[0033] (3) Add the zinc salt into the aqueous solution containing carboxymethyl cellulose, stir evenly to form a mixed solution, then add the acidic solution containing sulfide, and continue to stir evenly to obtain a mixed solution; the zinc salt is zinc chloride; the sulfide It is thioacetamide; the acidic solution is a...

Embodiment 2

[0039] (1) Add nano-titanium dioxide, activated carbon, and diatomaceous earth to polyethylene glycol, disperse evenly, and then perform high-pressure homogeneous heating to obtain an electrospinning solution; during high-pressure homogeneous heating, the pressure is 80MPa and the temperature is 100 ℃, the time is 40min;

[0040] Wherein: 15 parts by weight of nano-titanium dioxide, 8 parts by weight of activated carbon, 7 parts by weight of diatomaceous earth, and 70 parts by weight of polyethylene glycol;

[0041] (2) The electrospinning solution prepared in step (1) is subjected to an electrospinning process to make a titanium dioxide composite fiber;

[0042] (3) Add the zinc salt into the aqueous solution containing carboxymethyl cellulose, stir evenly to form a mixed solution, then add the acidic solution containing sulfide, and continue to stir evenly to obtain a mixed solution; the zinc salt is zinc nitrate; the sulfide is Thiourea; acidic solution is hydrochloric aci...

Embodiment 3

[0048] (1) Add nano-titanium dioxide, activated carbon, and diatomaceous earth into polyethylene glycol, disperse evenly, and then perform high-pressure homogeneous heating to obtain an electrospinning solution; during high-pressure homogeneous heating, the pressure is 100 MPa, and the temperature is 120 ℃, the time is 30min;

[0049] Wherein: 20 parts by weight of nano-titanium dioxide, 12 parts by weight of activated carbon, 10 parts by weight of diatomaceous earth, and 58 parts by weight of polyethylene glycol;

[0050] (2) The electrospinning solution prepared in step (1) is subjected to an electrospinning process to make a titanium dioxide composite fiber;

[0051] (3) Add the zinc salt into the aqueous solution containing carboxymethyl cellulose, stir evenly to form a mixed solution, then add the acidic solution containing sulfide, and continue to stir evenly to obtain a mixed solution; the zinc salt is zinc acetate; the sulfide It is sodium sulfide; the acidic solution...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap