Furnace slag separating equipment

A technology for separating equipment and slag, which is applied in the direction of solid separation, filter screen, grid, etc., can solve the problems of unfavorable use, old equipment, large loss, etc., and achieve the effect of reducing costs and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

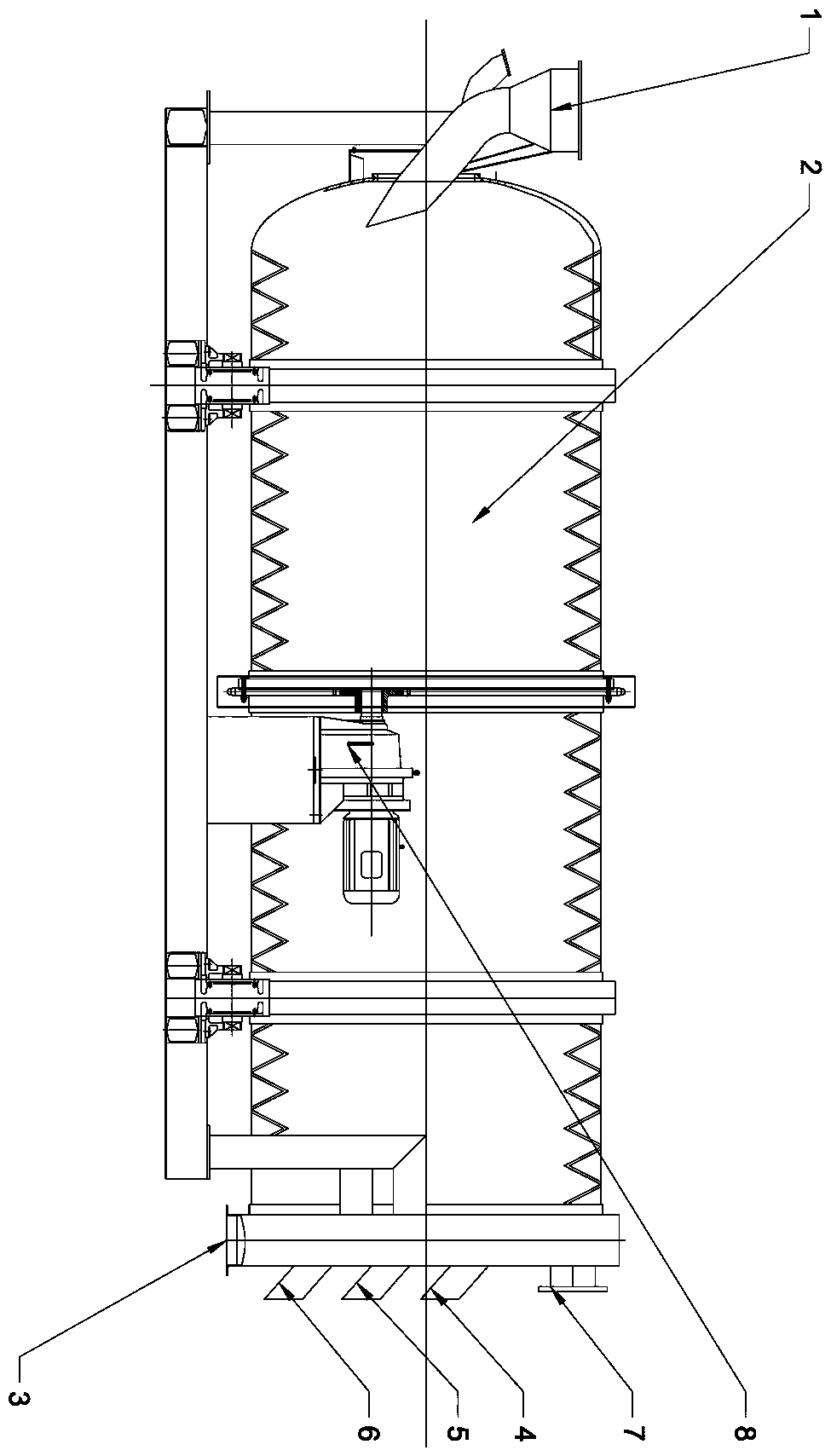

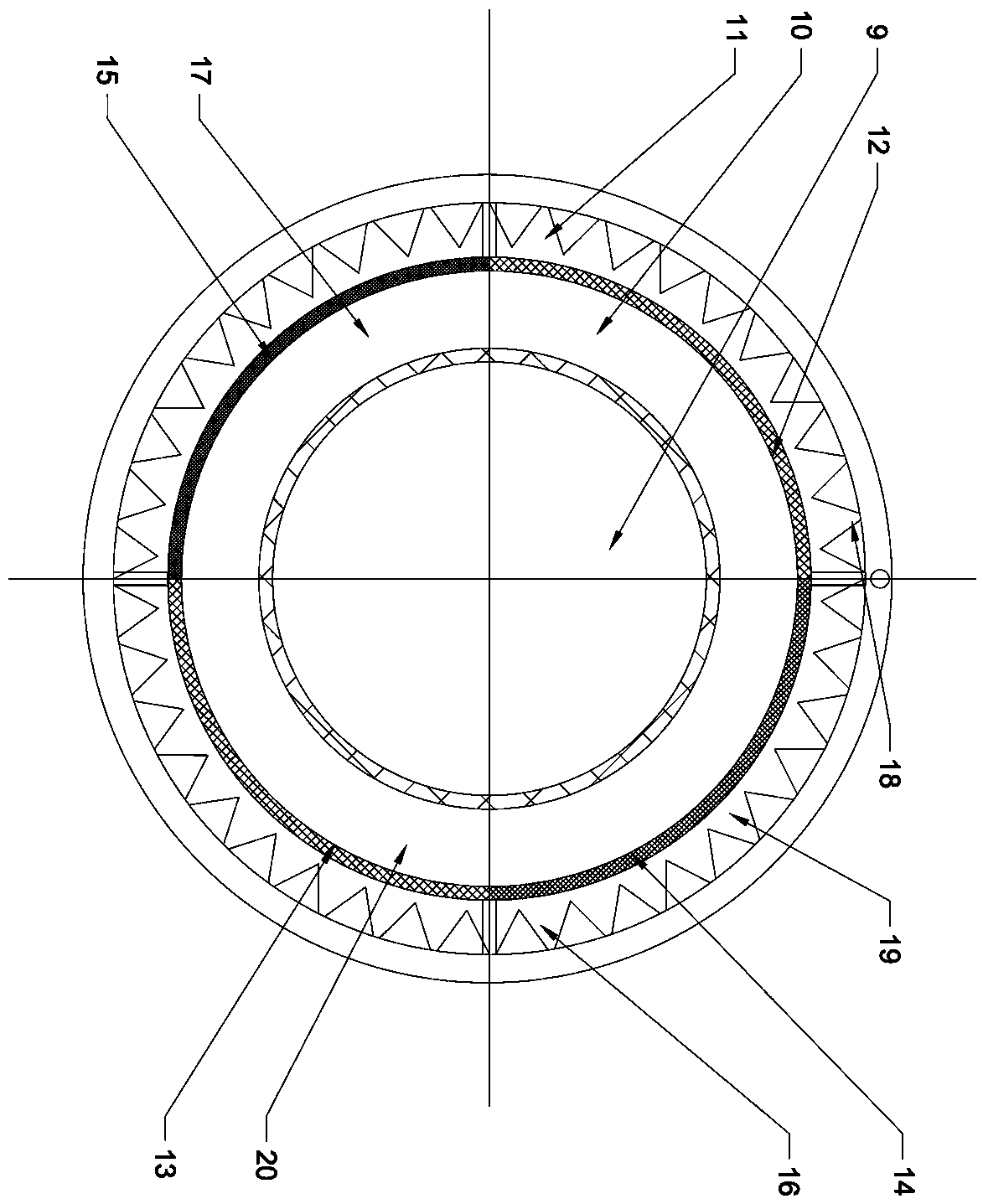

[0019] The object of the present invention is achieved in the following way: a slag separation equipment, comprising a main support frame, one side of the main support frame is equipped with a secondary support clip, the main support frame is equipped with a drum 2, and the auxiliary support A driving device 8 is provided on the supporting frame, a rotating assembly is provided on the outer periphery of the drum 2, and the driving device 8 is directly connected with the rotating assembly, an outlet is provided on one side of the drum 2, and an outlet is provided on the other side of the drum 2. There is an inlet 1; the drum 2 is provided with several layers of filter layers, and the drum 2 is also provided with a spray device 21, and the drum 2 is provided with a water inlet 7 in conjunction with the spray device 21, and the drum 2 is equipped with The water inlet 7 is provided with a water outlet 3; several layers of filter layers are correspondingly provided with respective o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com