Ultrasonic screening structure as well as on-line granularity analysis device formed by same and analysis method

A particle size analysis, ultrasonic technology, applied in the direction of particle size analysis, particle and sedimentation analysis, material analysis, etc., can solve the problems of carbon anode unit consumption increase, screen life is short, carbon anode quality decline, etc., to achieve short life, good quality Vibration performance, quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

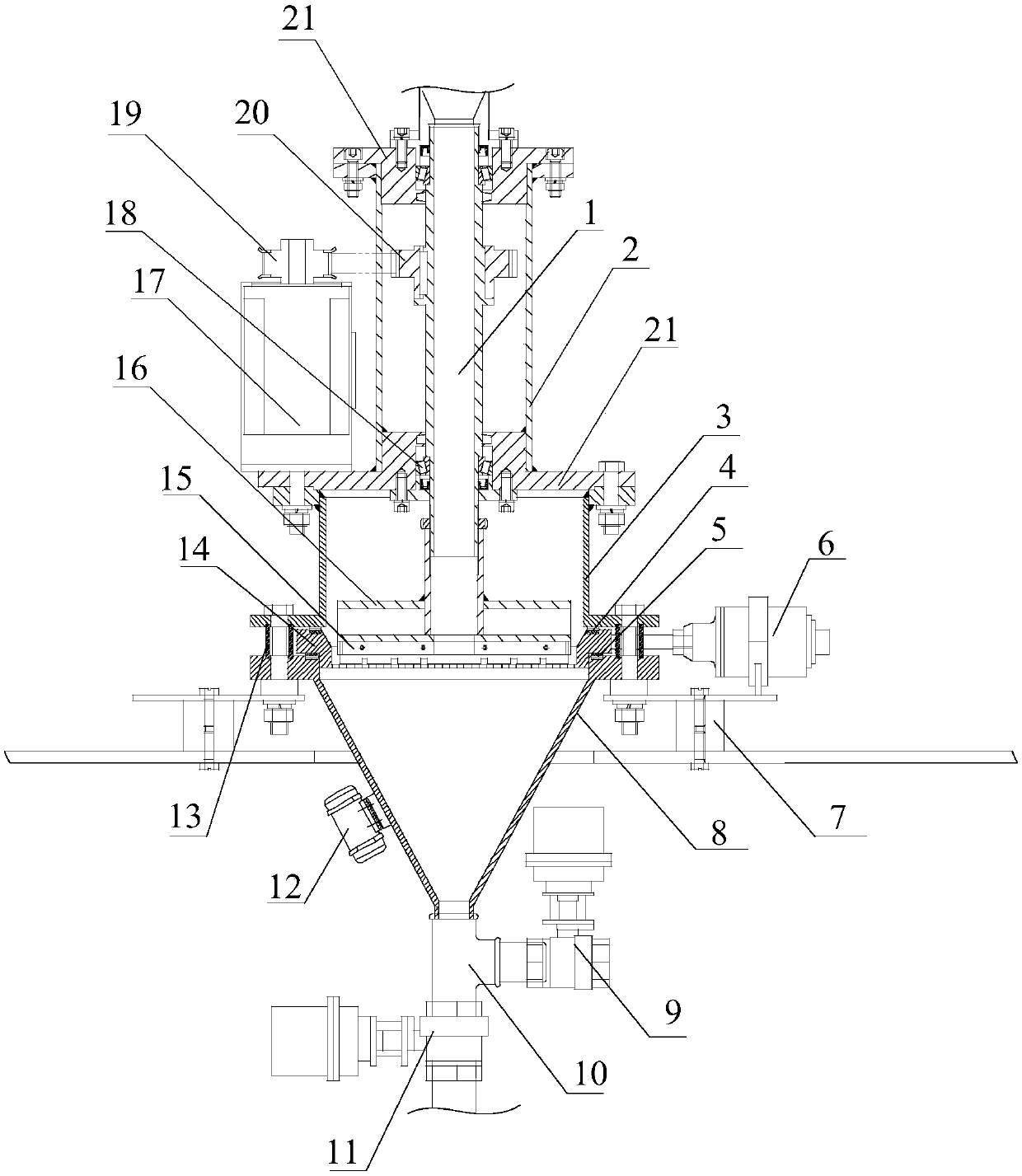

[0032] like figure 1 As shown, the ultrasonic sieving structure of this embodiment includes an under-sieve powder collection mechanism, a connecting seat 3, a vibrating sieve 14, a rotary blowing mechanism and a vibrating mechanism.

[0033]The under-sieve powder collection mechanism includes a bin body 8 arranged below the vibrating screen 14, a first three-way joint 10 installed on the discharge port of the bin body 8, and a first electric ball valve respectively installed on the first three-way joint 10. 9 and the second electric ball valve 11, and the vibration motor 12 arranged on the outer wall of the warehouse body 8. Specifically, the feed port end of the bin body 8 is provided with a flange, the connecting seat 3 has a cavity and flanges are connected at both ends, the flange on the bin body 8 and the flange at the lower end of the connecting seat 3 pass through Bolt connection; the vibrating screen 14 is installed between the bin body 8 and the connecting seat 3, an...

Embodiment 2

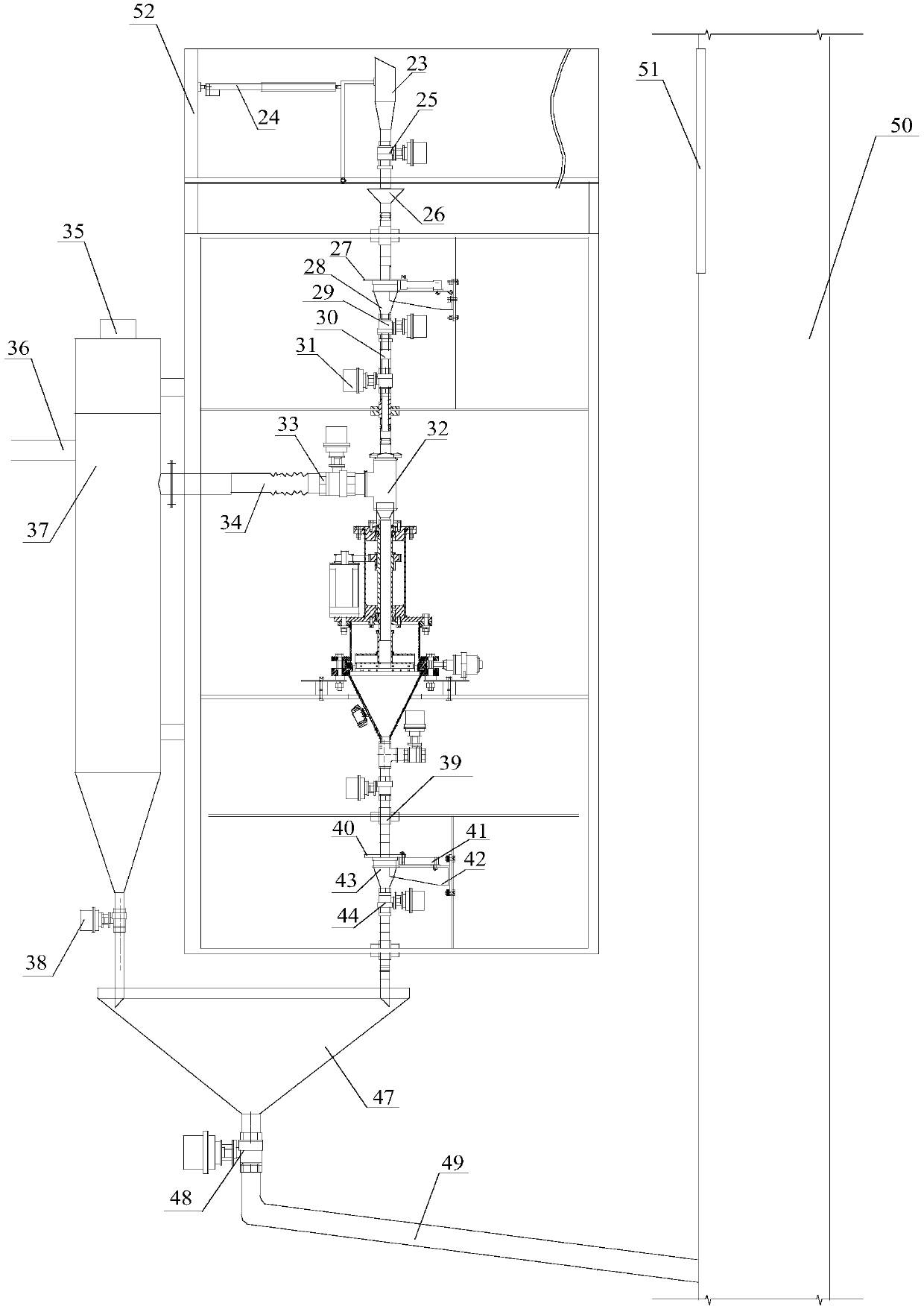

[0040] The present embodiment is an online particle size analysis device composed of the ultrasonic screening structure in Example 1, which includes all structures of the ultrasonic screening structure in Example 1; as figure 2 As shown, the online particle size analysis device of this embodiment also includes a computer system, a coarse powder recovery mechanism connected to the upper end of the hollow shaft 1, a sample powder weighing mechanism connected to the coarse powder recovery mechanism, and a sample powder weighing mechanism connected to the sample powder weighing mechanism. The sampling mechanism, the undersize powder weighing mechanism connected with the second electric ball valve 11, and the ash receiving mechanism respectively connected with the undersize powder weighing mechanism and the coarse powder recovery mechanism. The coarse powder recovery mechanism, sample powder weighing mechanism, sampling mechanism, under-sieve powder weighing mechanism and ash recei...

Embodiment 3

[0052] This embodiment adopts the analysis method of the online particle size analysis device formed by the ultrasonic screening structure in Embodiment 2, which comprises the following steps:

[0053] (1) Sampling; the computer system controls the seventh electric ball valve 25 to close, and controls the electric push rod 24 to promote the spring door 51 of the sampling hopper 23 to push open the process pipeline 50, so that the sampling hopper 23 enters the process pipeline 50 to collect the sample material. After the material collection is completed, the computer system controls the electric push rod 24 to drive the sampling hopper to return to the top of the receiving hopper 26 to complete sampling.

[0054] (2) Tare detection of the sample powder hopper scale; start the sample powder hopper scale 28 to perform the tare detection of the sample powder hopper scale, and transmit the tare data to the computer system.

[0055] (3) Sample material is weighed; Computer system cl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap