Vacuum degreasing sintering molding method

A technology of vacuum degreasing and sintering molding, which is applied in the field of industrial furnaces, and can solve the problems of incomplete removal of vapor wax, pollution of the furnace body and sintering quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

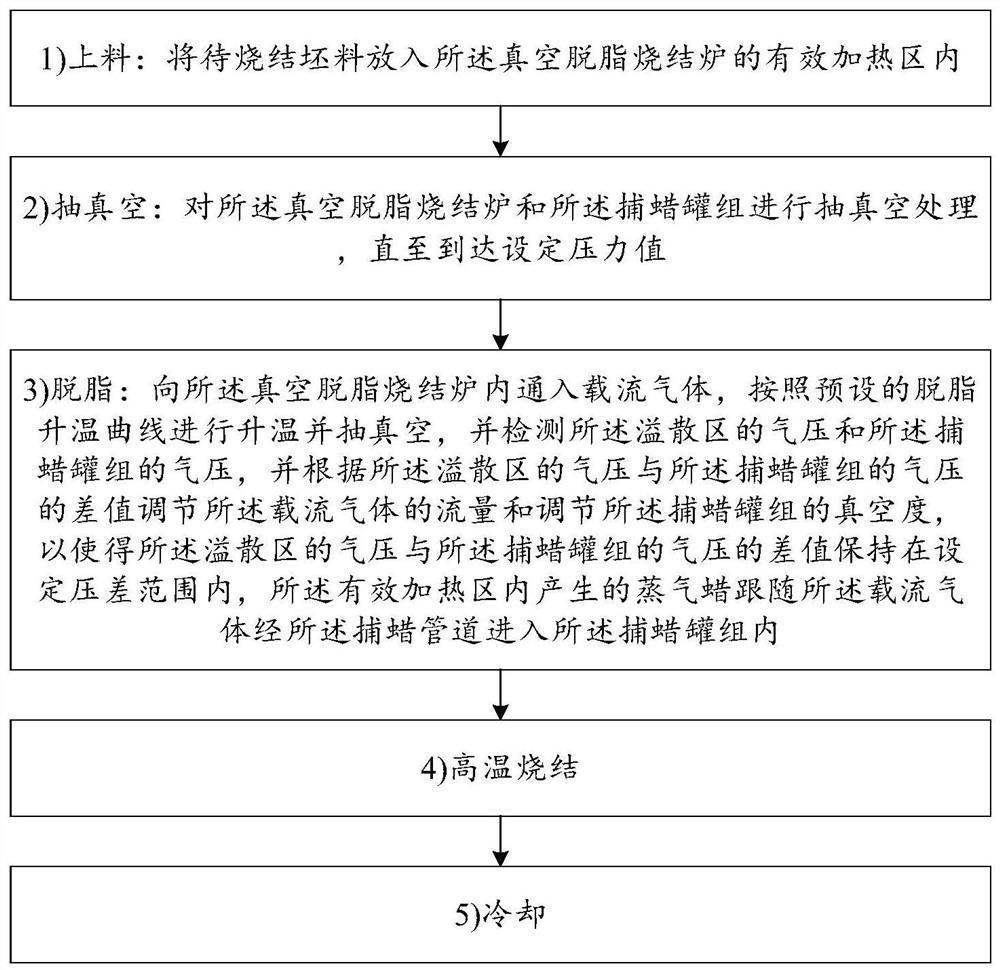

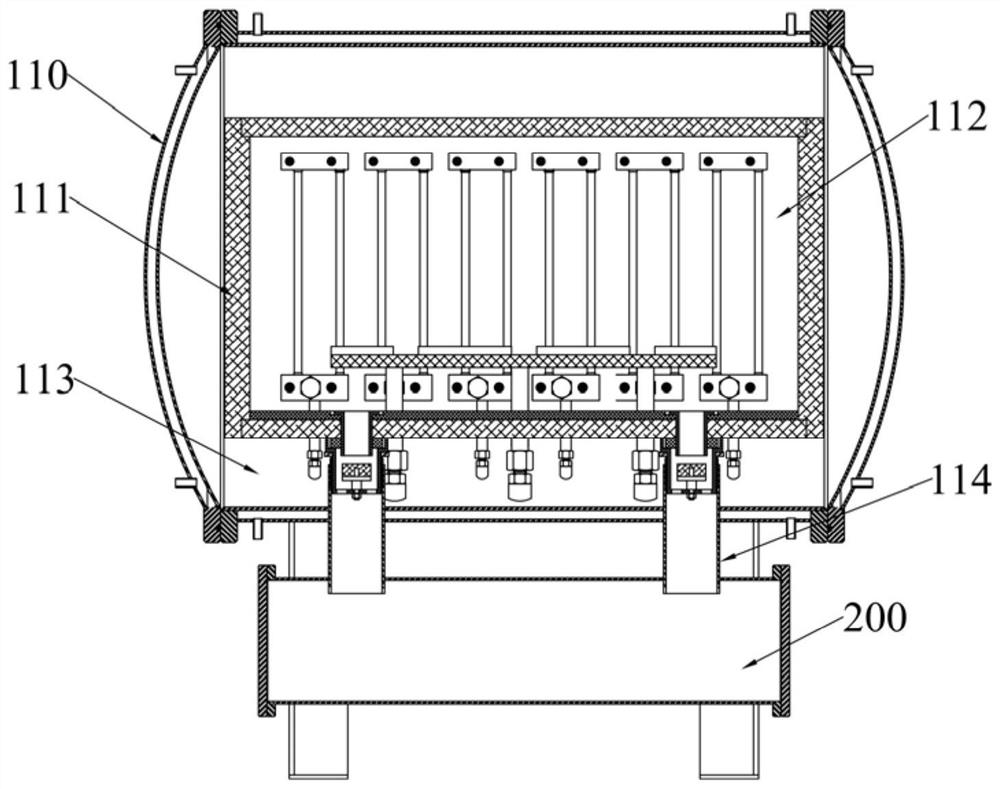

[0050] 1) Loading: put the aluminum alloy billet to be sintered into the effective heating zone 112 of the vacuum degreasing sintering furnace 100:

[0051] 2) Vacuuming: Vacuumizing the vacuum degreasing sintering furnace 100 and the wax trap group 200 until the pressure is 6 Pa;

[0052] 3) Degreasing: Inert gas is introduced into the vacuum degreasing sintering furnace 100, heated from room temperature to 500° C. at a heating rate of 2° C. / min, kept for 1 hour, and vacuumed at the same time. Detect the air pressure of the overflow area 113 and the air pressure of the wax trap group 200, and adjust the flow rate of the inert gas and the vacuum degree of the wax trap group so that the difference between the air pressure of the overflow area 113 and the wax trap group 200 Keep at 15 kPa, the vapor wax produced in the effective heating zone 112 follows the inert gas and enters the wax trapping tank group 200 through the wax trapping pipeline 114;

[0053] 4) high temperature s...

specific Embodiment 2

[0058] 1) Loading: put the alumina blank to be sintered into the effective heating zone 112 of the vacuum degreasing sintering furnace 100:

[0059] 2) Vacuuming: Vacuumizing the vacuum degreasing sintering furnace 100 and the wax trap group 200 until the pressure is 10 Pa;

[0060] 3) Degreasing: Introduce nitrogen gas into the vacuum degreasing sintering furnace 100, heat from room temperature to 600°C at a heating rate of 4°C / min, keep it warm for 1.5 hours, and pump vacuum at the same time. Detect the air pressure of the overflow area 113 and the air pressure of the wax trap group 200, and adjust the flow of nitrogen and the vacuum degree of the wax trap group so that the difference between the air pressure of the overflow area 113 and the wax trap group 200 remains At 20 kPa, the vapor wax produced in the effective heating zone 112 enters the wax trap group 200 through the wax trap pipeline 114 along with the nitrogen gas;

[0061] 4) high temperature sintering;

[0062...

specific Embodiment 3

[0066] 1) Loading: Put the stainless steel billet to be sintered into the effective heating zone 112 of the vacuum degreasing sintering furnace 100:

[0067] 2) Vacuuming: Vacuumizing the vacuum degreasing sintering furnace 100 and the wax trap group 200 until the pressure is 15 Pa;

[0068] 3) Degreasing: Inert gas is introduced into the vacuum degreasing sintering furnace 100, heated from room temperature to 500°C at a heating rate of 2°C / min, and kept at a temperature of 1 hour, while vacuuming, and detecting the air pressure and wax capture in the overflow area 113 The air pressure of the tank group 200, and the flow rate of the inert gas is adjusted and the vacuum degree of the wax trap group is adjusted so that the difference between the air pressure of the overflow area 113 and the gas pressure of the wax trap group 200 remains at 25 kPa, and the effective heating zone 112 The vapor wax produced in the interior follows the nitrogen gas and enters the wax-catching tank g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com