High-performance rutile carbon steel welding rod

A rutile-type, high-performance technology, applied in the direction of welding medium, welding equipment, metal processing equipment, etc., can solve the problems of poor comprehensive mechanical properties of metals, unstable cracking resistance of electrodes, physical injury of welders, etc., and achieve weld bead forming Smooth surface, high coating strength and excellent crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

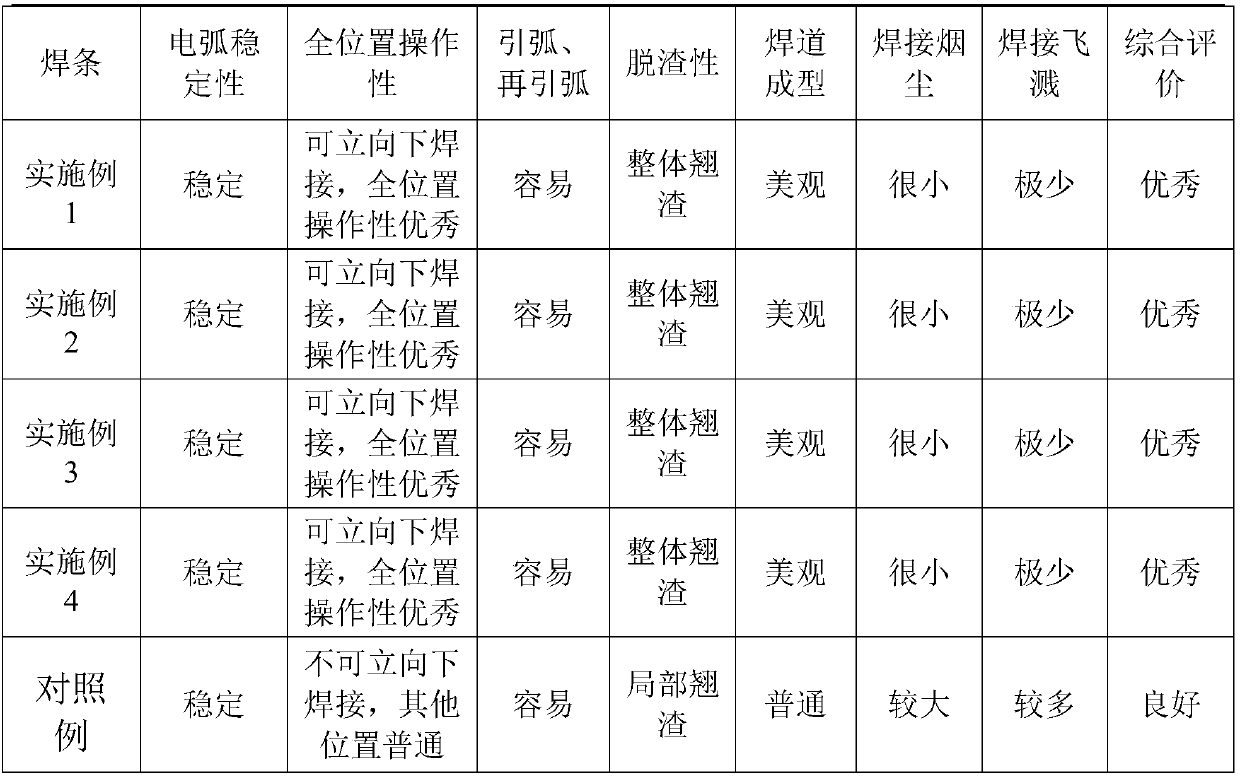

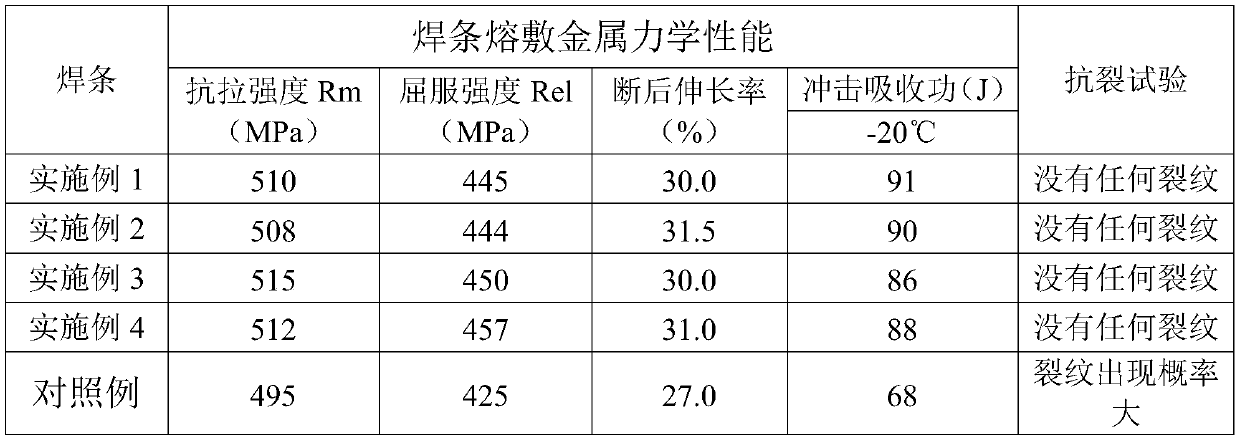

Examples

Embodiment 1

[0036] A high-performance rutile carbon steel electrode, the coating includes the following components in parts by weight: 45 parts of rutile, 20 parts of quartz, 11 parts of marble, 10 parts of medium carbon ferromanganese, 13 parts of kaolin, microcrystalline fiber 8 parts of vegetable, 5.5 parts of starch, 3 parts of titanium dioxide.

Embodiment 2

[0038] A high-performance rutile carbon steel electrode, the coating includes the following components in parts by weight: 47 parts of rutile, 17 parts of quartz, 13 parts of marble, 9 parts of medium carbon ferromanganese, 11 parts of kaolin, microcrystalline fiber 6 parts of vegetable, 4 parts of starch, 2 parts of titanium dioxide.

Embodiment 3

[0040] A high-performance rutile carbon steel electrode, the coating includes the following components in parts by weight: 49 parts of rutile, 15 parts of quartz, 16 parts of marble, 8 parts of medium carbon ferromanganese, 9 parts of kaolin, microcrystalline fiber 5 parts of plain, 5 parts of starch, 3 parts of titanium dioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com