ICT intelligent detecting and marking system

An intelligent detection and transfer technology, which is applied in closed-circuit television systems, typewriters, printing, etc., can solve the problems of wrong marking positions, missed printing, low manual operation efficiency, and affecting production line efficiency, so as to achieve accurate marking and reduce labor costs. Simple and reasonable cost and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

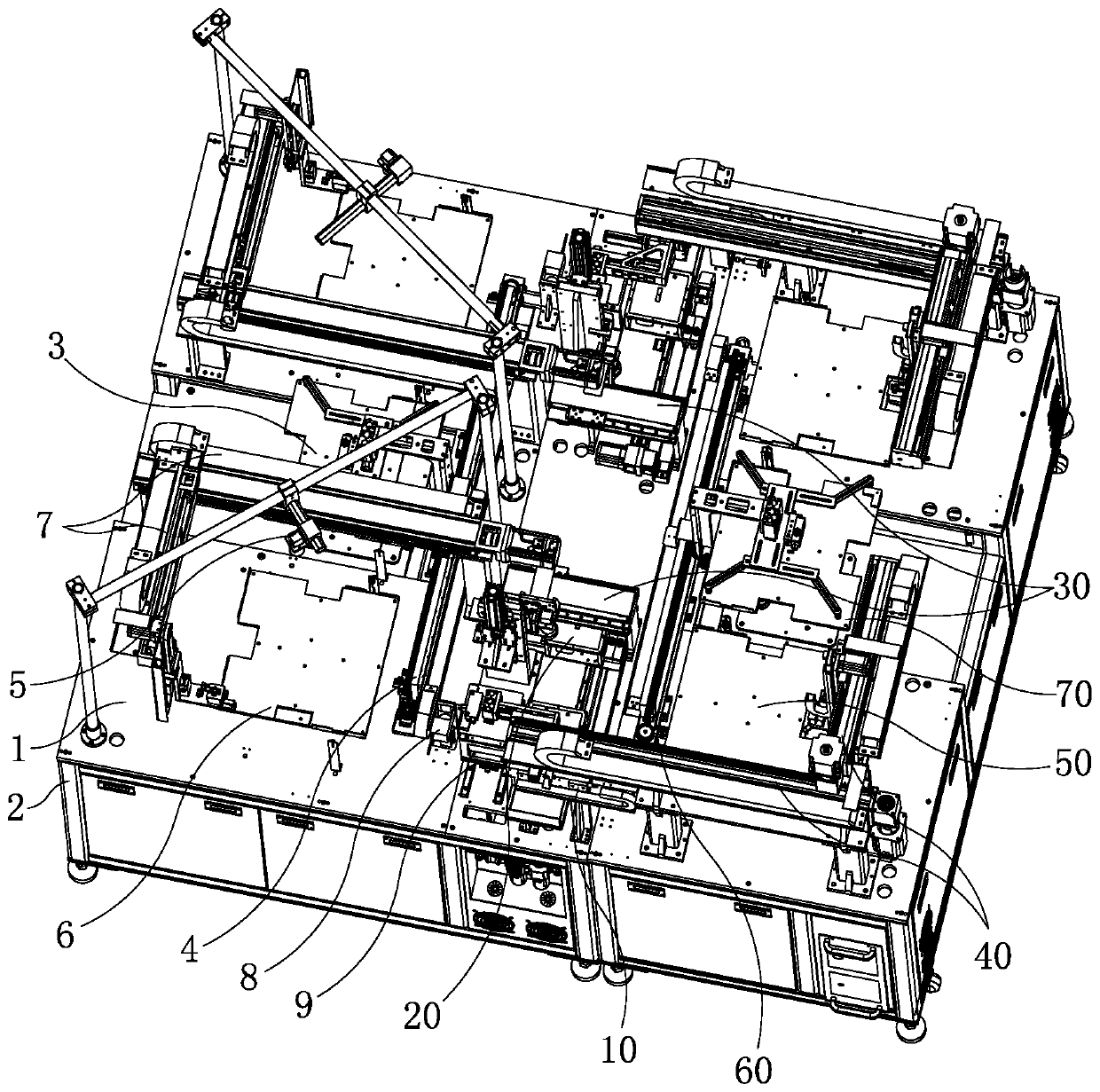

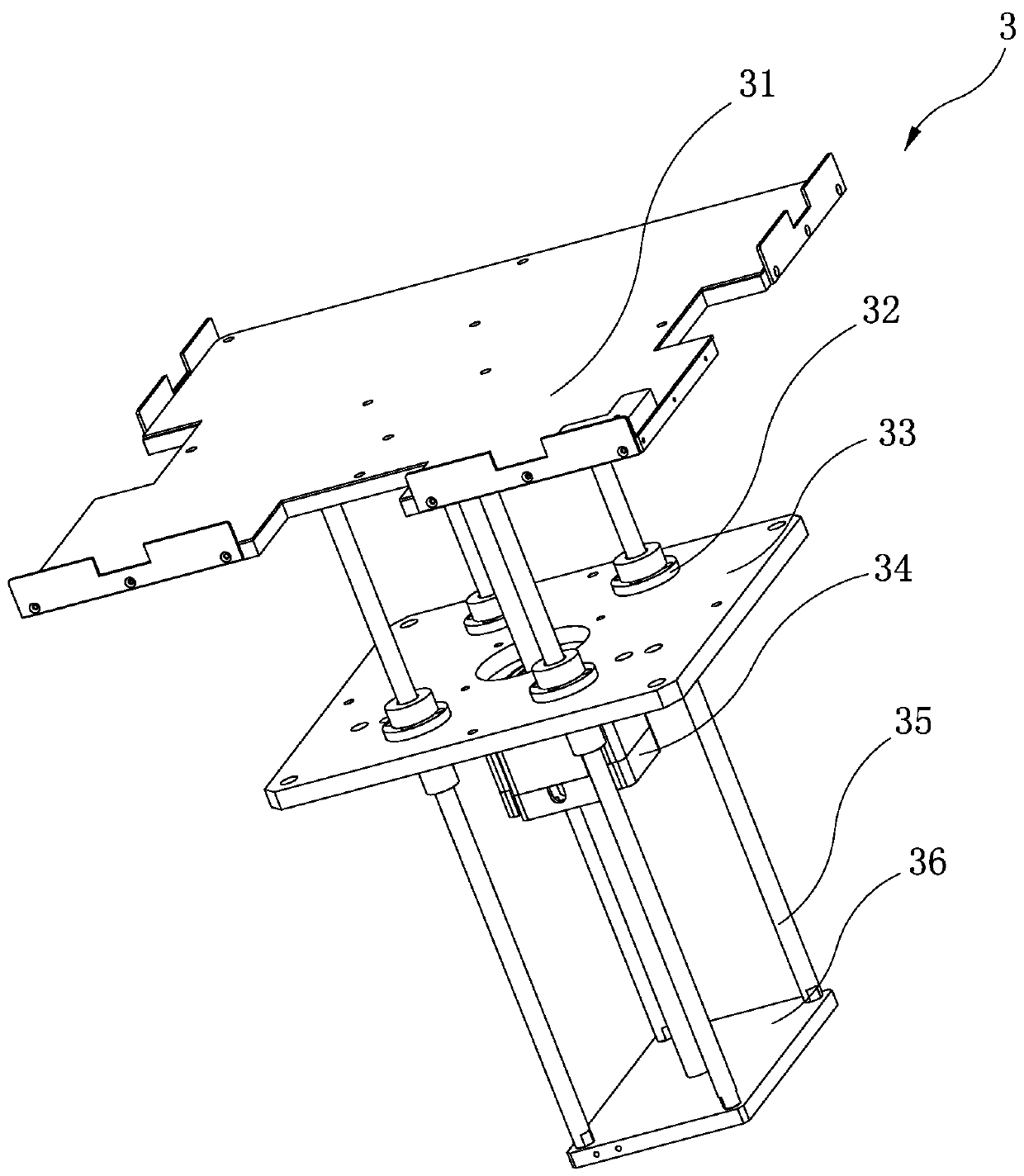

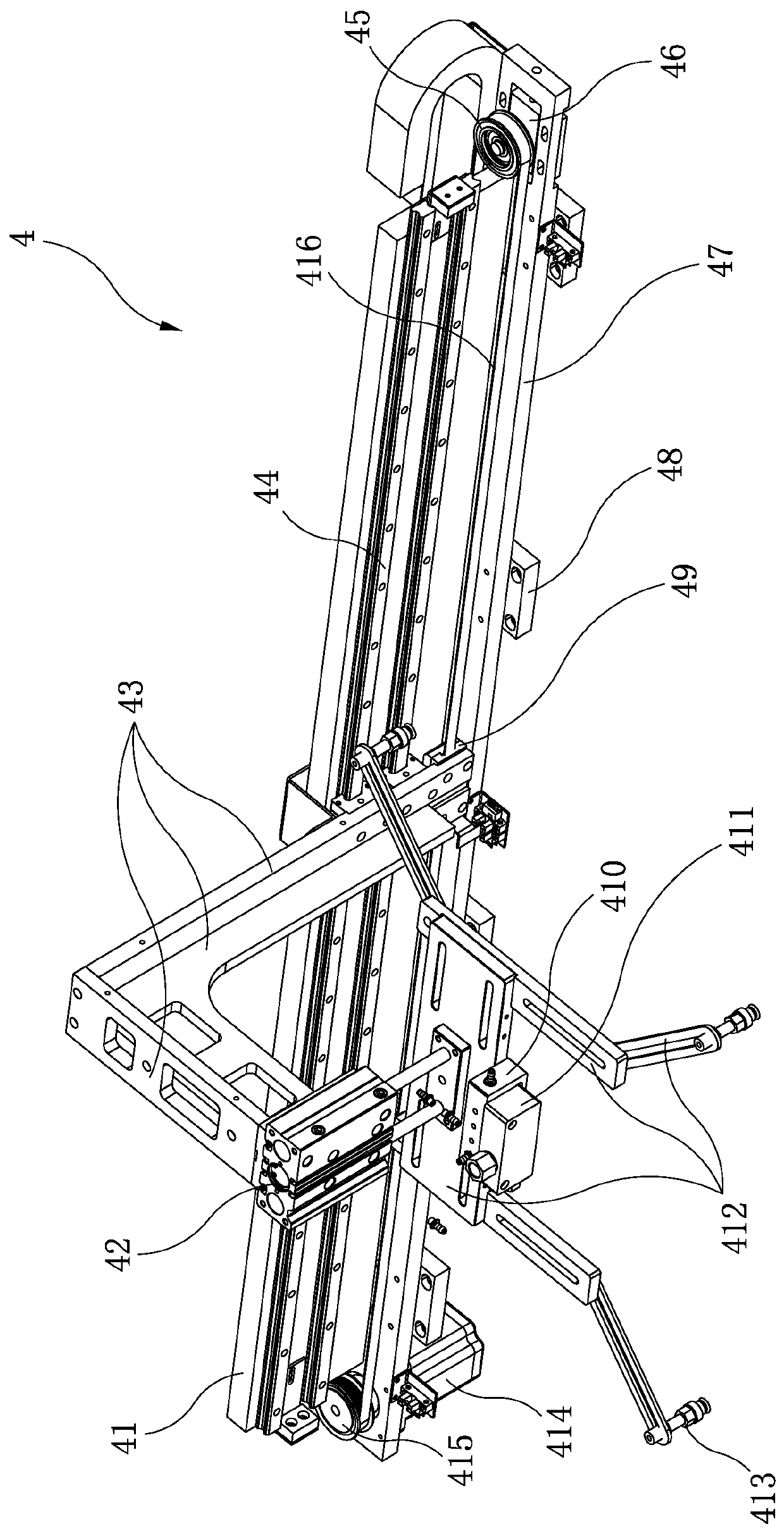

[0052] Such as figure 1 As shown, the present invention is an ICT intelligent detection and marking system, which is a fully automatic equipment integrating loading and unloading, automatic detection, visual recognition and marking. It includes a large base plate 1, an equipment rack 2, a feeding lifting Mechanism 3, feeding and changing mechanism 4, feeding visual recognition mechanism 5, feeding and lifting mechanism 6, feeding and transporting mechanism 7, angle visual recognition mechanism 8, testing mechanism 9, retrieving mechanism 10, feeding and transporting mechanism 20. A marking mechanism 30 , a material discharging and transporting mechanism 40 , a blanking and lifting mechanism 50 , a blanking and changing mechanism 60 , and a discharging and lifting mechanism 70 .

[0053] The large bottom plate 1 is fixed on the equipment frame 2, the feeding lifting mechanism 3, the feeding plate changing mechanism 4, the feeding visual recognition mechanism 5, the feeding lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com