Automotive air conditioner assembly structure

An automotive air conditioner and assembly structure technology, which is applied to vehicle parts, air handling equipment, heating/cooling equipment, etc., can solve the problems of large air conditioner structure layout, impossibility of general use, unfavorable automobile platform production, etc., and achieve the goal of optimizing the structure layout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

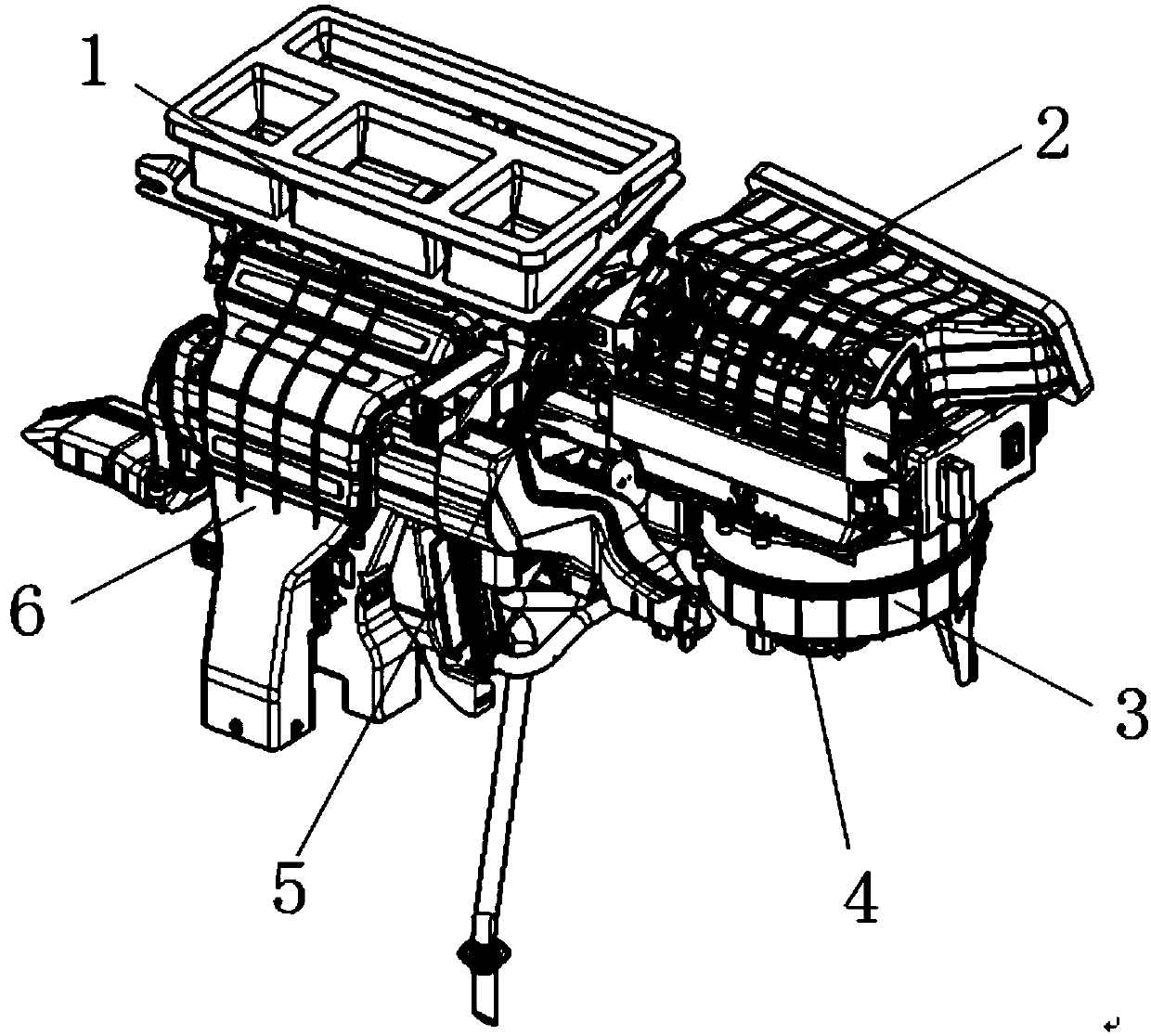

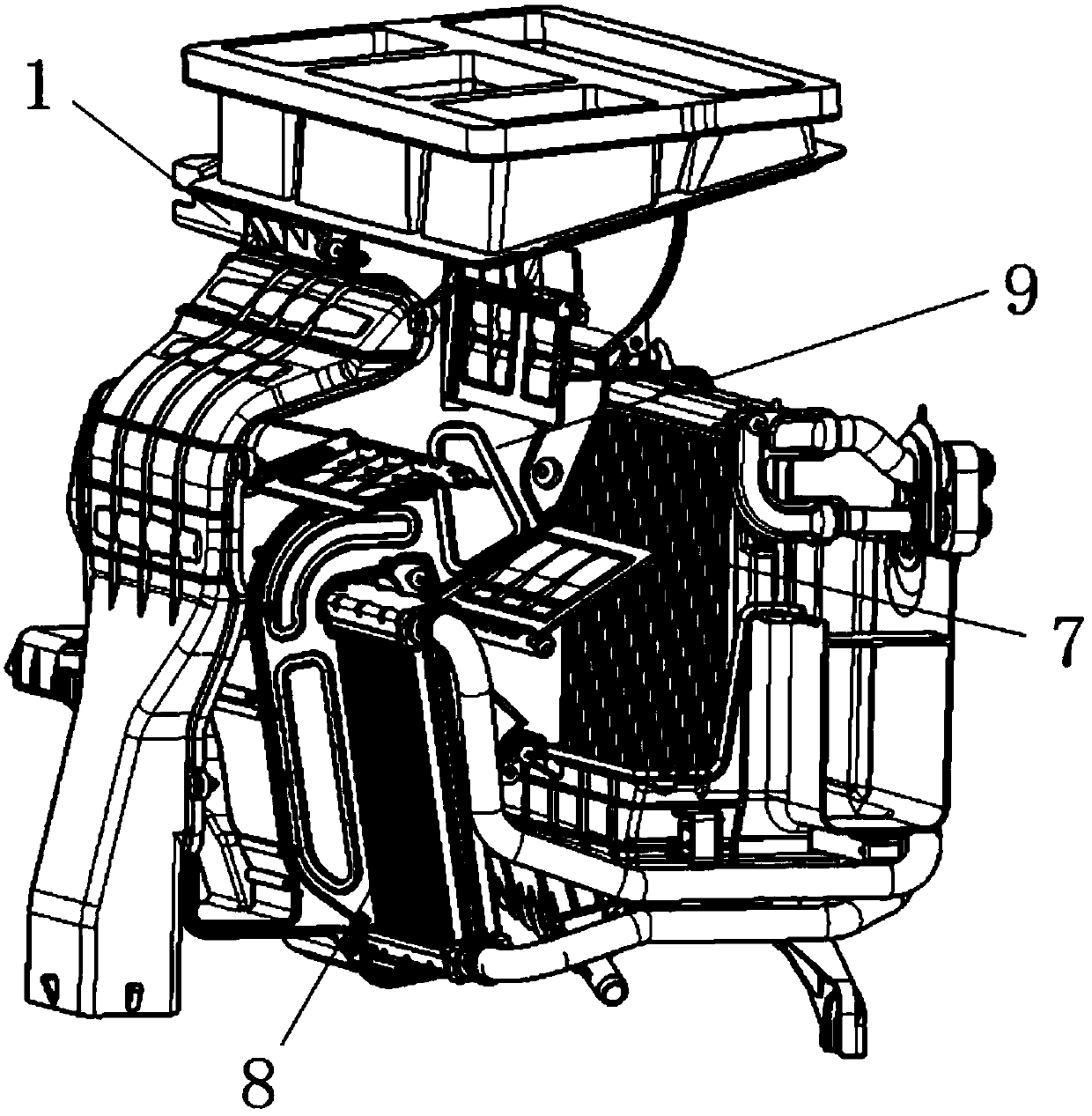

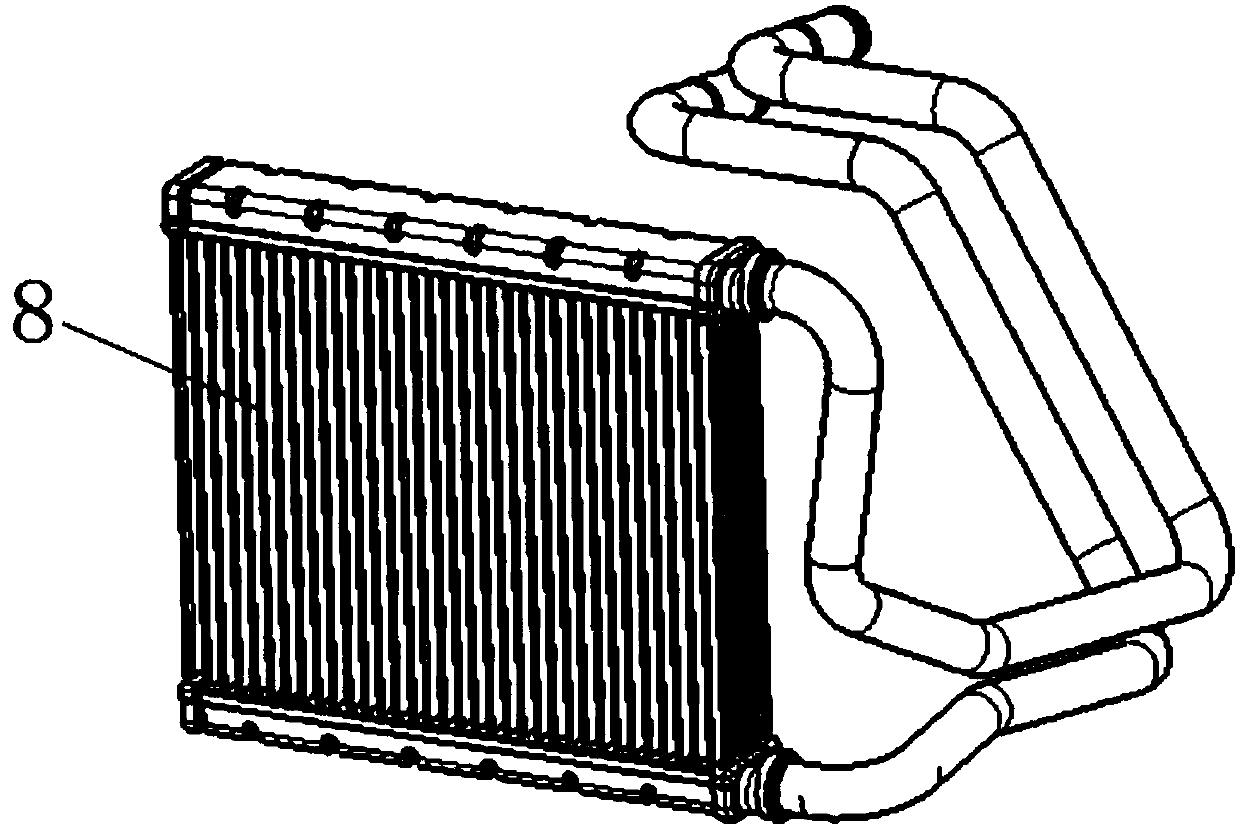

[0014] Such as Figure 1 to Figure 4 A car air conditioner assembly structure shown, including distributor assembly 1, air inlet assembly 2, volute assembly 3, blower assembly 4, evaporator assembly 7, heater assembly 8, air inlet assembly 2 is arranged on the side of the distributor assembly 1, and the air inlet assembly 2, the volute assembly 3, and the blower assembly 4 are sequentially superimposed and connected to form a whole. Both the evaporator assembly 7 and the heater assembly 8 are arranged inside the distributor assembly 1, so as to achieve a compact layout and reduce the external size.

[0015] The distributor assembly 1 is respectively connected with the double-drive driving mechanism and the single-drive driving mechanism. The distributor assembly 1 is provided with a middle partition 9, and the middle partition 9 is connected with the evaporator assembly 7 and the heater assembly 8 respectively. The partition 9 takes into account the single-drive and double-dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com