Clip type caterpillar band stacking machine

A stacker and clip-type technology, which is applied in the field of stackers, can solve the problems of cumbersome discharging and feeding actions and affect the working efficiency of the stacker, and achieve the effects of convenient operation, convenient feeding and unloading, and low man-hour consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

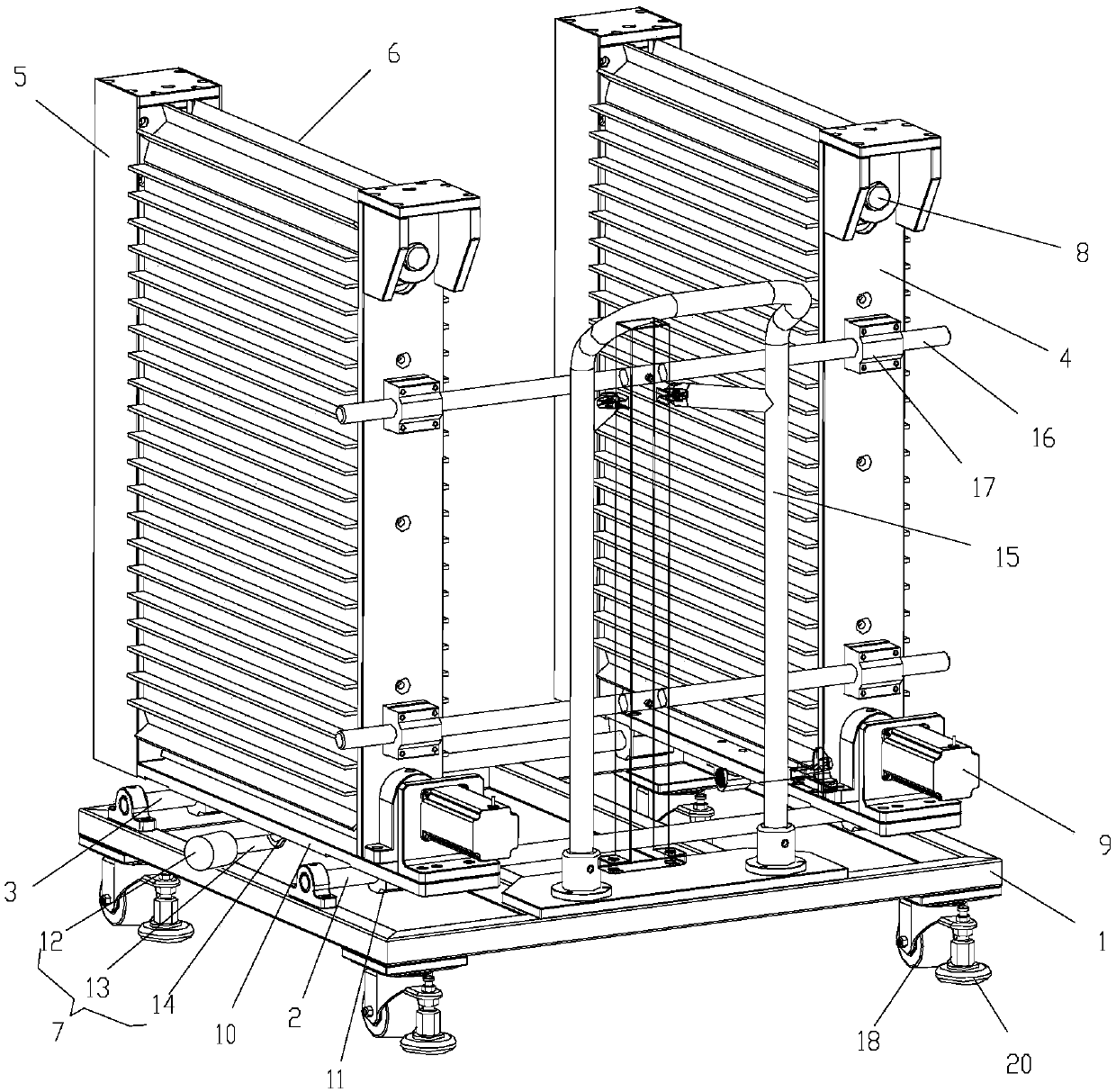

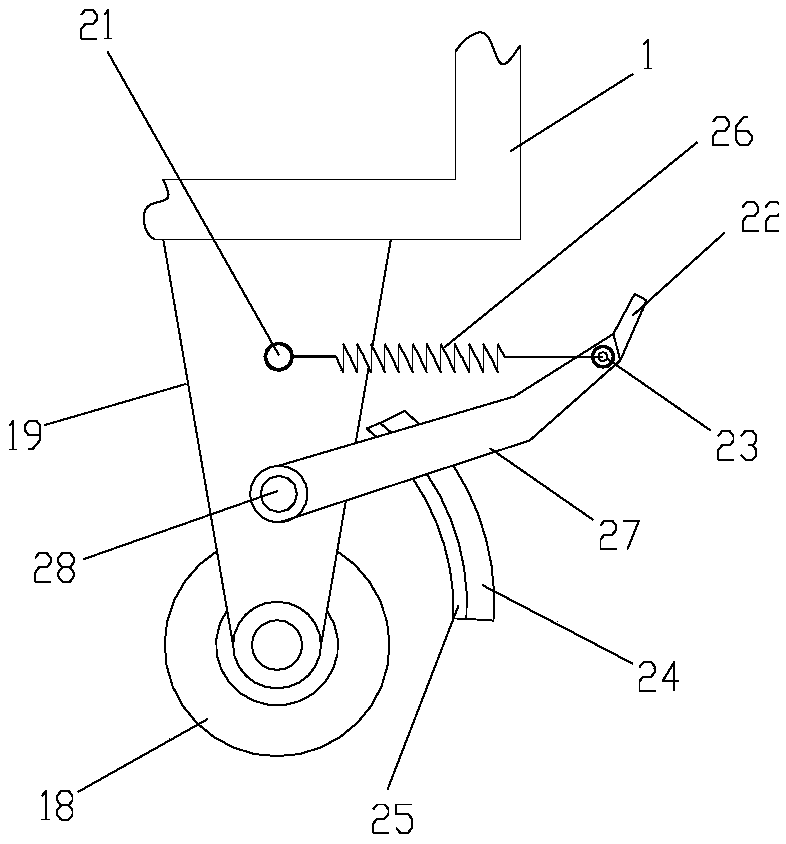

[0024] see Figure 1 to Figure 2 Shown is the first preferred embodiment of the clip-type crawler stacker of the present invention, the clip-type crawler stacker includes a base 1, a first support rod 2, a second support rod 3, and a first support plate 4 , the second support plate 5, the crawler belt 6 and the rotating mechanism 7, the first support rod 2 and the second support rod 3 are arranged relatively parallel on the base 1, as preferably, the base 1 is a square structure, and the first support The rod 2 and the second support rod 3 are circular rod-shaped structures, and the first support rod 2 and the second support rod 3 are arranged perpendicular to the base 1, and the first support plates 4 are respectively arranged at both ends of the first support rod 2 , the second support plate 5 is arranged at both ends of the second support rod 3 respectively, and a rotating shaft 8 is arranged between the first supporting plate 4 and the second supporting plate 5 at the same...

Embodiment approach 2

[0030] see figure 1Shown is the second preferred embodiment of the clip-type crawler stacker of the present invention. The difference between this embodiment and the first embodiment is that the crawler belt 6 is a grooved crawler belt, which is set as a groove The purpose of the crawler track: for the products to be stacked, it is necessary to use auxiliary layers such as backing plates and rubber strips to be stacked, and the life of auxiliary products such as backing plates and rubber strips is short, and frequent replacement of backing plates, rubber strips and other materials is required, which affects the stacking height. The working efficiency of the machine, accordingly, the present invention aims at the above-mentioned problems, and sets the crawler belt 6 as a slotted type, so that the product to be stacked can be fixed only by being stuck in the crawler belt 6, eliminating the need for The existing backing plate, rubber strip and other materials are used, and the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com