A watch shaker take-up and pay-off device

A technology of retracting and releasing wires and cranking handles, which can be used in instruments, measuring resistance/reactance/impedance, measuring devices, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

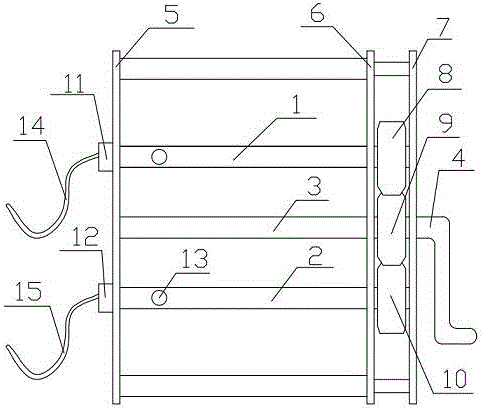

[0014] A meter take-up and take-off device, including an outer frame, a grounding bobbin 1, a phase bobbin 2, a rocker shaft 3 and a rocker 4; the outer frame includes a first partition 5, a second partition 6 and a third partition 7. The rocker shaft 3, the grounding bobbin 1 and the phase bobbin 2 are located between the first partition 5 and the second partition 6, the crank shaft 3 is located in the center of the first partition 5, the grounding bobbin 1 and the phase connection The spools 2 are respectively located on the horizontal sides of the rocker shaft 3 and arranged at intervals; a first gear 8, a second gear 9 and a third gear 10 are arranged between the second partition 6 and the third partition 7, and the three gears Engage sequentially; the end of the first gear 8 close to the second partition 6 is connected to the grounding bobbin 1, and the end of the first gear 8 close to the third partition 7 is connected to the shaft passing through the third partition 7; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com