Sterilization logistics transportation system and method

A conveying system and logistics technology, used in conveyors, mechanical conveyors, transportation and packaging, etc., can solve problems such as uncoordinated and mismatched production capacity, and logistics lines cannot be conveyed normally, so as to avoid congestion and lack of vehicles, and ensure normal reliability. And the effect of continuous operation and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

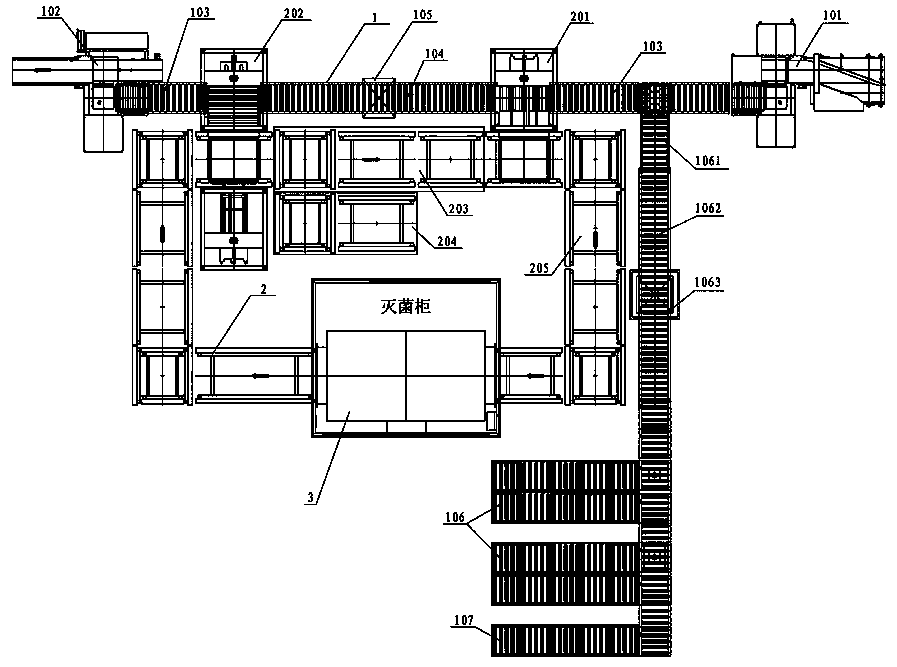

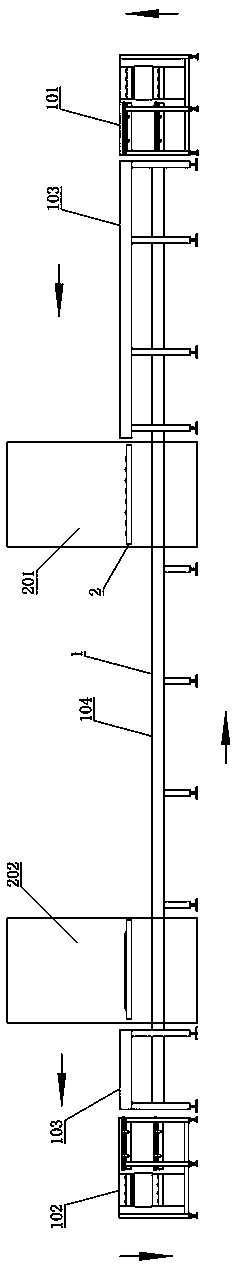

[0030] Such as figure 1 and figure 2 As shown, the sterilization logistics conveying system of this embodiment includes a sterilizing tray conveying line 1 and a sterilizing vehicle conveying line 2, and the sterilizing tray conveying line 1 includes a tray loading unit 101, a tray unloading unit 102 and a tray return line 104, The sterilizing vehicle conveying line 2 includes a loading unit 201, an unloading unit 202 and a return line 203. The two ends of the loading unit 201 are connected to the tray loading unit 101 and the sterilization cabinet 3 respectively, and the two ends of the unloading unit 202 are connected to the unloading unit 202 respectively. The disk unit 102 is docked with the sterilization cabinet 3; the disk loading unit 101 and the unloading unit 102 are connected through the return line 104; the loading unit 201 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com