Large conveyor loading and unloading platform car

A loading and unloading platform and transporter technology, which is applied in the directions of transportation and packaging, motor vehicles, loading/unloading, etc., can solve problems such as difficulty in turning around, poor maneuverability, and large turning radius, so as to achieve flexible transportation, reduce requirements, and avoid secondary problems. The effect of loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

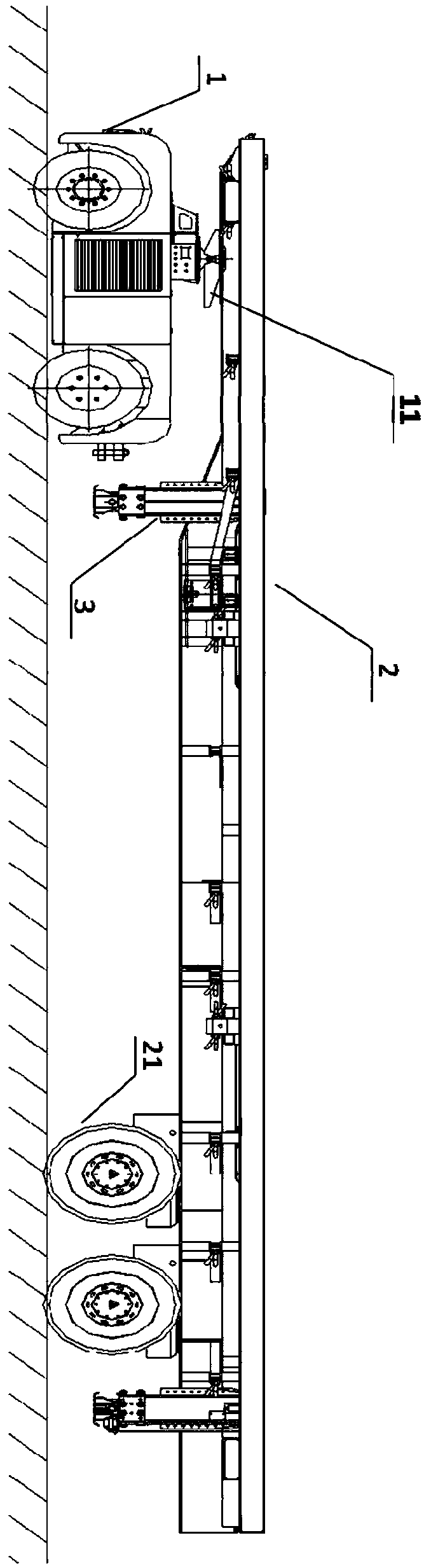

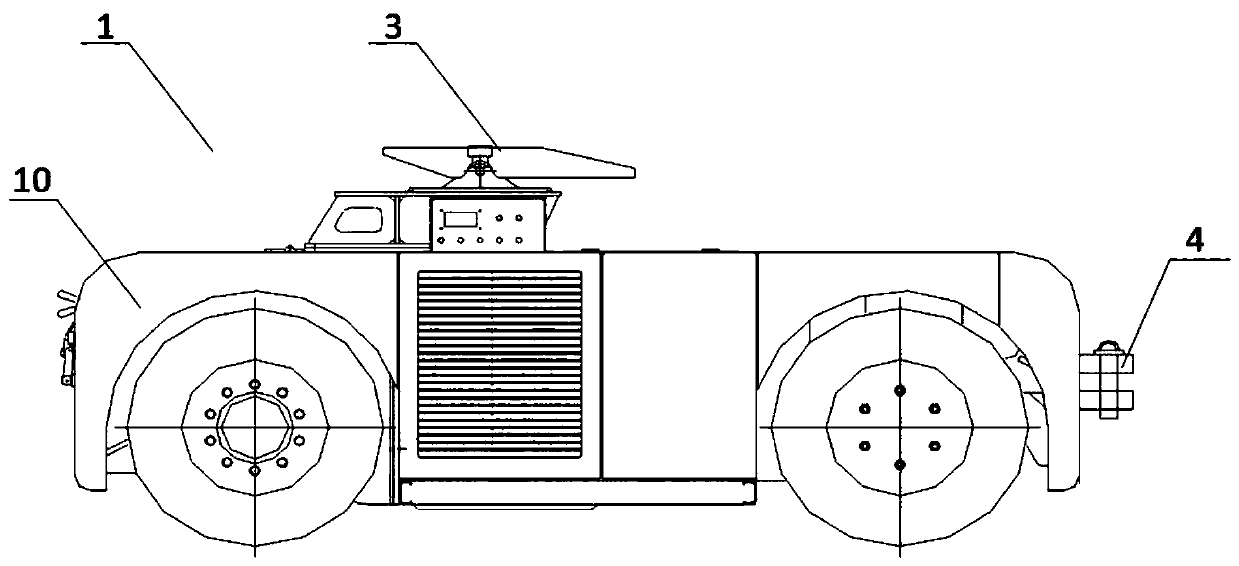

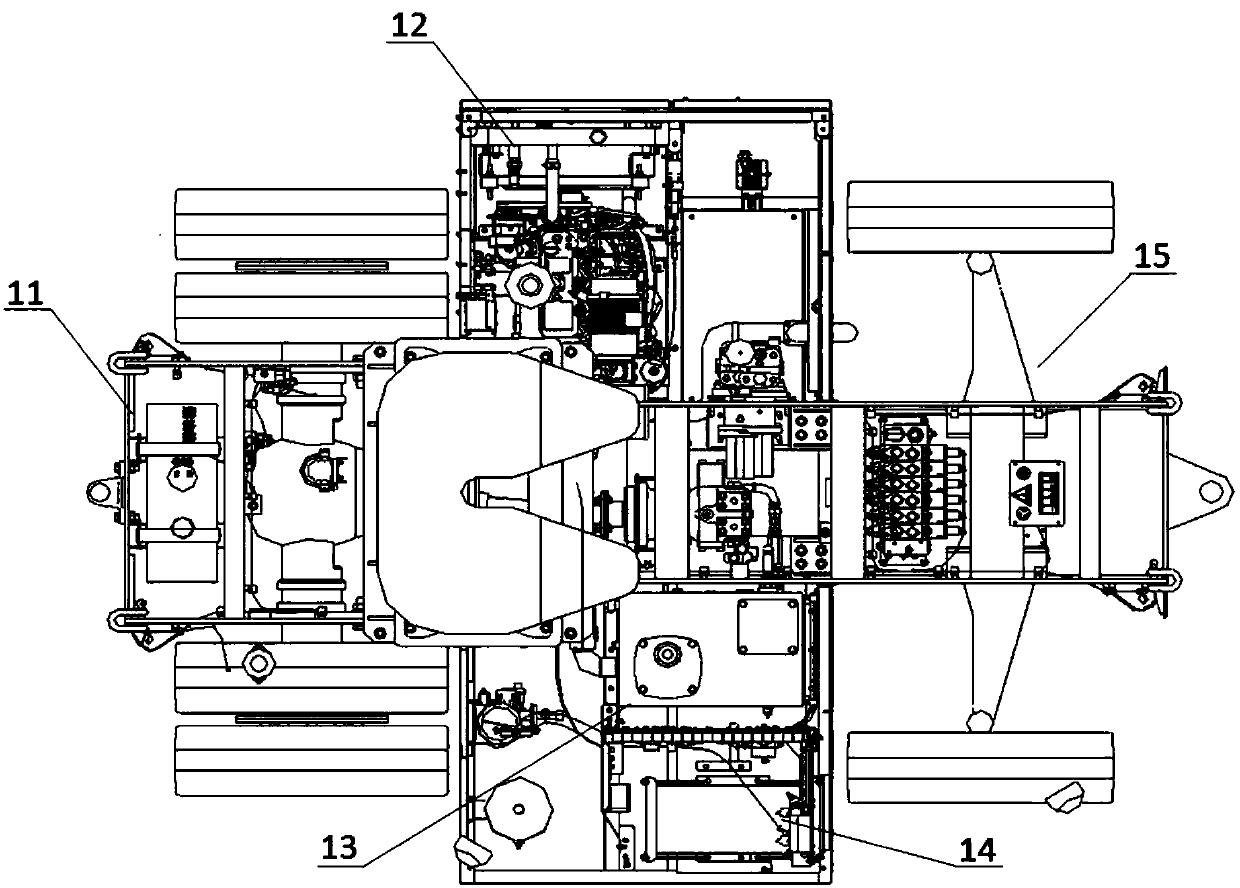

[0021] like Figure 1-4 As shown, a loading and unloading platform vehicle for a large transport aircraft includes a saddle tractor 1 and a loading and unloading platform 2. The front section of the loading and unloading platform 2 is specifically installed on the saddle tractor 1 . The specific structure and connection of the above two devices are as follows: the lower end of the loading and unloading platform 2 is fixedly equipped with a telescopic outrigger 3, and the telescopic outrigger 3 is preferably stretched and contracted by a hydraulic cylinder. Two pairs of telescopic supporting legs 3 are two pairs in total, and two pairs of telescopic supporting legs 3 are distributed on the front and rear sections of loading and unloading platform 2 . like figure 1 As shown, the pair of telescopic outriggers located in the front section are located at the rear position of the front section of the loading and unloading platform 2, and the pair of telescopic outriggers located i...

Embodiment 2

[0033] In this embodiment, the saddle tractor 1 pulls the cargo trolley through the traction bolt 4 at the rear end, so as to realize the transportation of the cargo trolley and avoid reloading and unloading of the cargo.

Embodiment 3

[0035] to combine figure 1 and Figure 5 , this embodiment discloses a mode of cargo transportation and loading and unloading.

[0036] When the saddle tractor 1 pulls the loading and unloading platform 2 through the top saddle 3, it enters the cargo transportation mode, which is suitable for loading, unloading and driving of cargo, especially for transportation in narrow areas. When the saddle tractor 1 pulls the cargo trolley through the traction bolt 4 at the rear end, it realizes the short-distance transportation of the cargo, especially the full container transportation of the cargo, avoids secondary handling, and can directly transport and load, greatly saving manpower.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com