Coal mine gas pre-extracting drilling flexible hole sealing system and method

A technology for coal mine gas and gas drainage, which is applied in gas discharge, mining equipment, earthwork drilling, etc., can solve the problems of huge material consumption, inability to seal new cracks, and inability to recycle sealing devices, so as to reduce costs and protect Environment, effect of reduction in usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

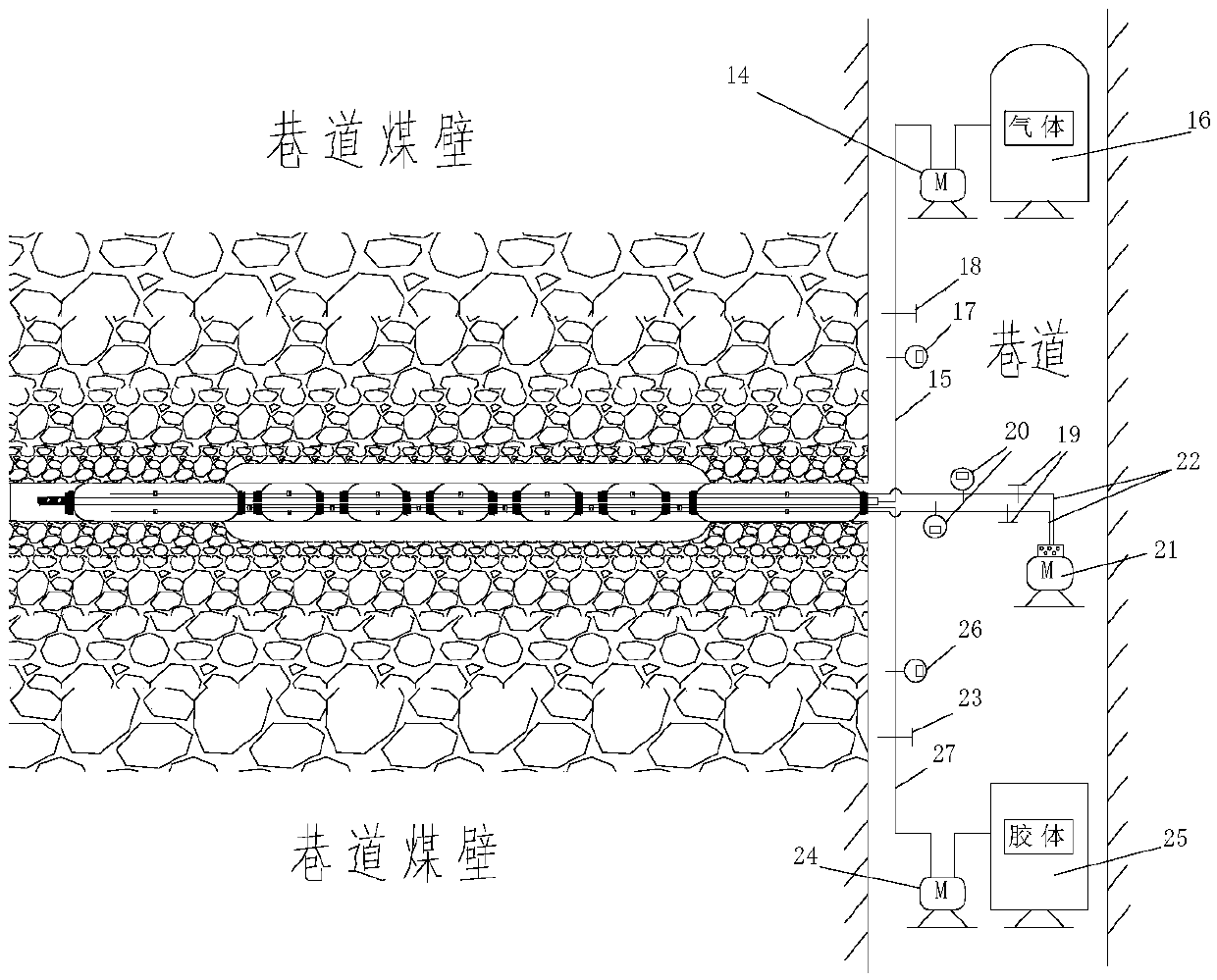

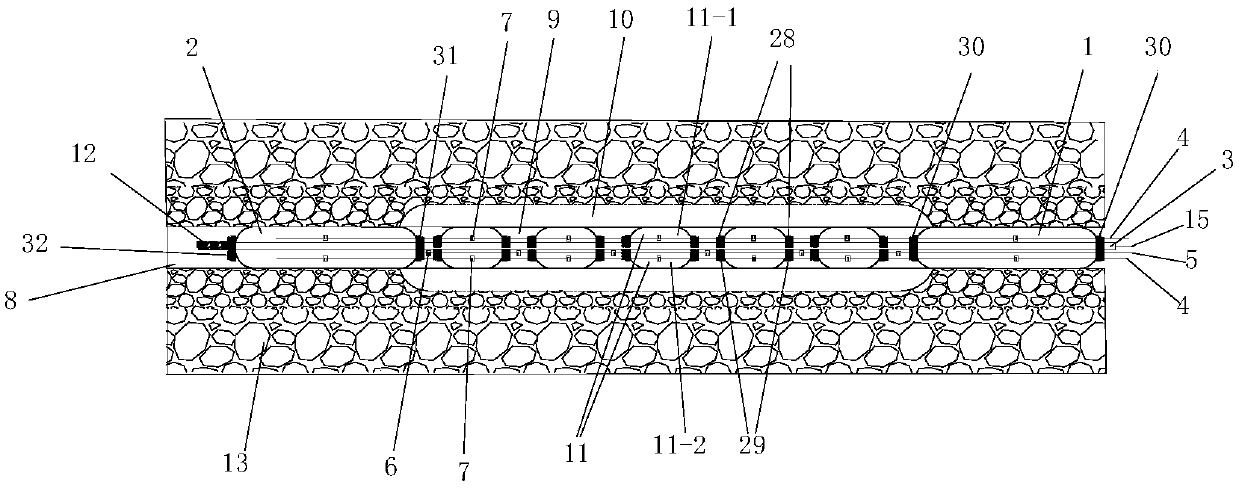

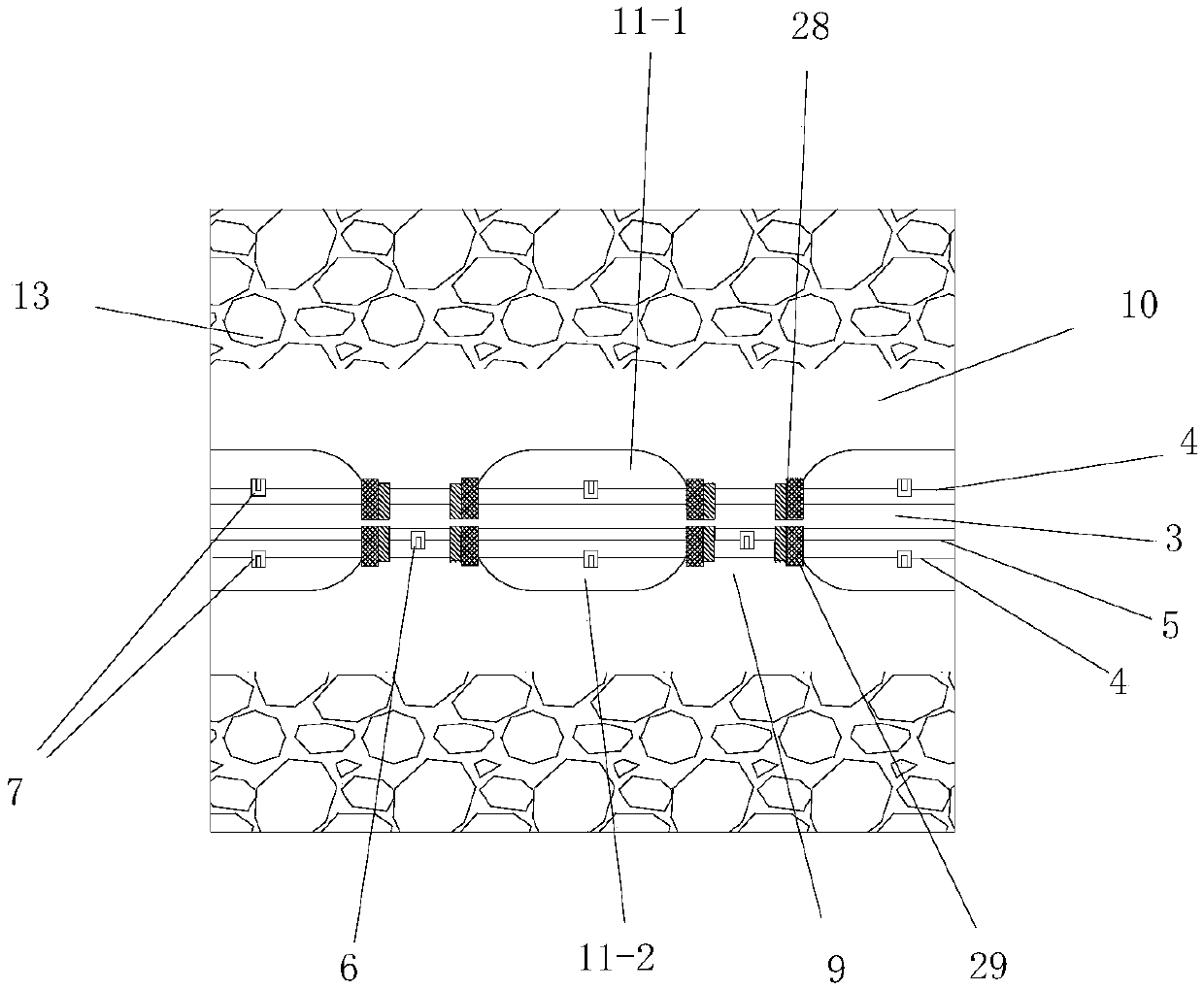

[0053] A coal mine gas pre-extraction drilling flexible sealing system of the present invention, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, it includes a sealing mechanism, a gas drainage mechanism and a grouting mechanism. The sealing mechanism includes a drainage pipe 3, a grouting pipe 5 and two pressure pipes arranged side by side in the gas pre-extraction borehole space 8 4. The gas pre-extraction borehole space 8 has one end for gas extraction as the inner end and the other end as the outer end. The gas pre-extraction borehole space 8 is sequentially provided with a front airbag 1 and an intermediate airbag from outside to inside 11 and the rear airbag 2, the middle airbag 11 is composed of an upper airbag and a lower airbag arranged symmetrically up and down, the extraction pipe 3 passes through the front airbag 1 and the rear airbag 2, and is sandwiched between the upper airbag of the middle airbag 11 Between the airbag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com