Method for weakening coal seam hard roof based on electric pulse technology

A hard roof and electric pulse technology, applied in earth square drilling, surface mining, underground mining, etc., can solve the problems of rock formation weakening, large water consumption, resource waste, etc., and achieve simple operation, wide application range, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

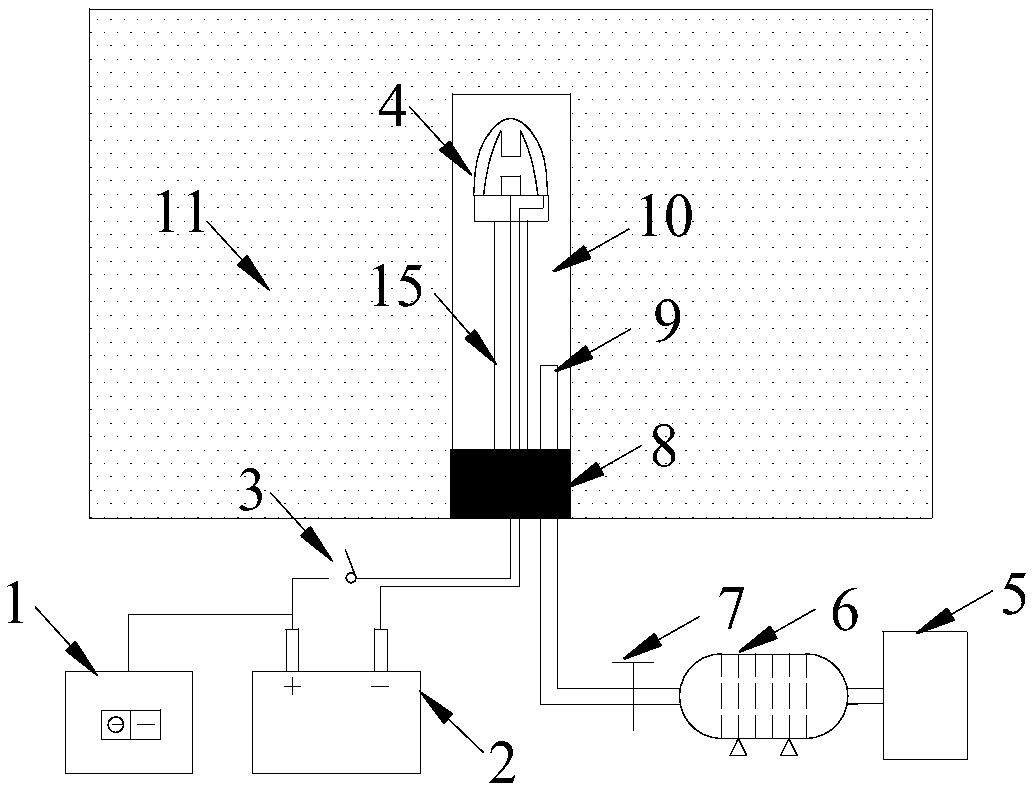

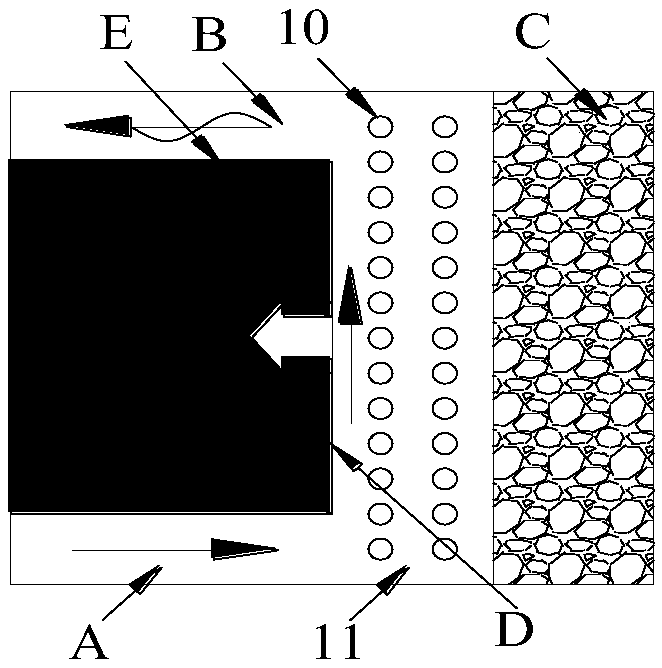

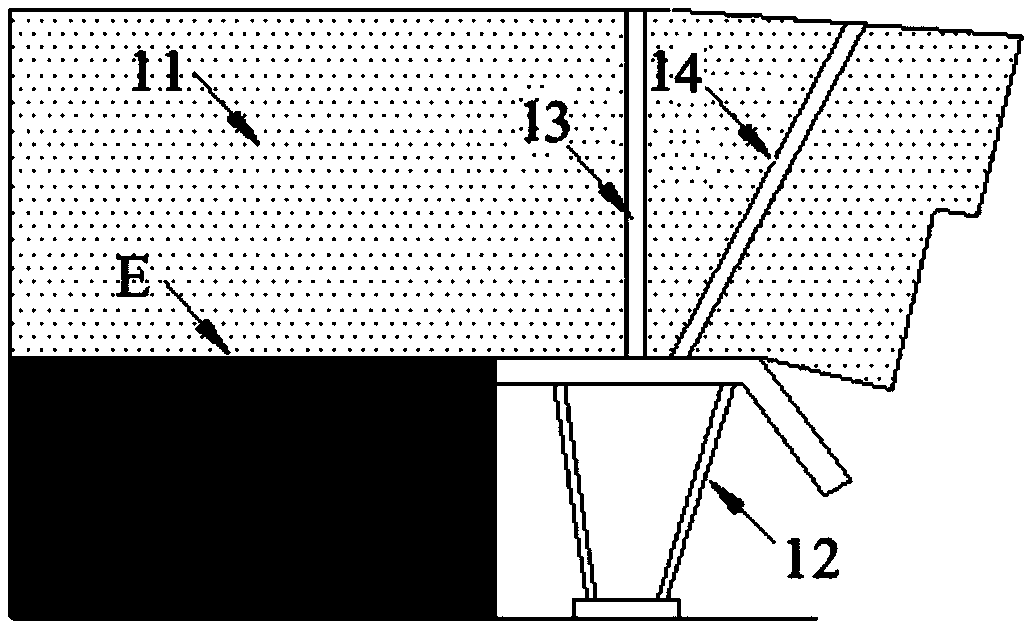

[0024] Such as figure 1 , 2 As shown in and 3, a method for weakening the hard roof of a coal seam based on electric pulse technology includes steps:

[0025] a. When the coal seam E is recovered, two rows of fracturing boreholes 10 with a diameter of 10 cm are constructed in the gap between the two hydraulic supports 12 to the roof 11 using a conventional drilling method. The distance is 3m; the first row of fracturing boreholes 13 is perpendicular to the roof, the angle between the second row of fracturing boreholes 14 and the first row of fracturing boreholes 13 is 45°, and the second row of fracturing boreholes 14 Tend to goaf C.

[0026] b. After the construction of the fracturing drilling 10 is completed, install the discharge device,

[0027] Fix the discharge electrode 4 on the front end of the high-voltage cable protective tube 15, one end of the high-voltage cable is connected to the discharge electrode 4, and the other end of the high-voltage cable passes through...

Embodiment 2

[0036] Such as figure 1 , 2 A method for weakening the hard roof of a coal seam based on electric pulse technology shown in 3 includes steps:

[0037] a. When the coal seam E is recovered, two rows of fracturing boreholes 10 with a diameter of 10 cm are constructed in the gap between the two hydraulic supports 12 to the roof 11 using a conventional drilling method. The distance between the first row of fracturing boreholes 13 is perpendicular to the roof, the angle between the second row of fracturing boreholes 14 and the first row of fracturing boreholes 13 is 45°, and the second row of fracturing boreholes 14 Tend to goaf C.

[0038] b. After the construction of the fracturing drilling 10 is completed, install the discharge device,

[0039] Fix the discharge electrode 4 on the front end of the high-voltage cable protective tube 15, one end of the high-voltage cable is connected to the discharge electrode 4, and the other end of the high-voltage cable passes through the hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com