A cyclone-type clogged cavitator for decomposing excess sludge

A swirl type, cavitator technology, applied in the direction of oxidation treatment of sludge, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of ring-type clogged cavitators that are easy to block and collapse , to achieve the effects of simple structure, improved cavitation strength, and high cracking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

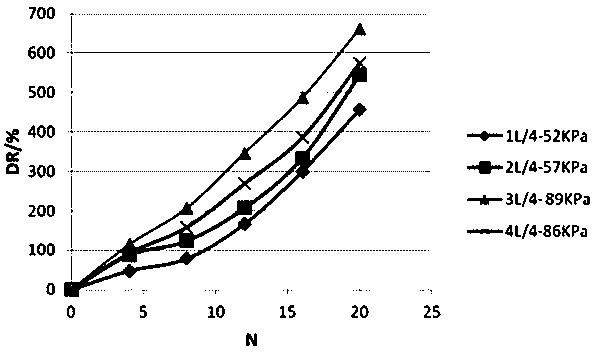

[0022] 1) Implementation parameters of the present invention

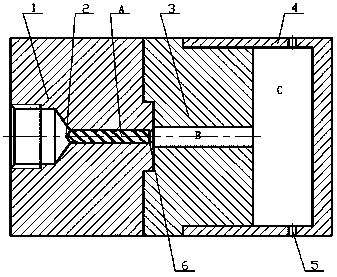

[0023] Such as figure 1 , the swirl body 1 and the choke body 3 are connected by bolts, the swirl core 2 and the swirl body 1 adopt a tight clearance fit, and there is a 0.4mm step 6 at the outlet end of the swirl core 2 for axial positioning, and the choke body 3 It is connected with the back pressure cover 4 with a cylindrical pin, and the swirl body 1 is connected with the external water supply pipe with threads. Each connection part adopts the corresponding sealing form. The equivalent diameter of the swirl nozzle is 3.2 mm, the diameter of the collapse chamber is 90 mm, and the axial length is 30 mm.

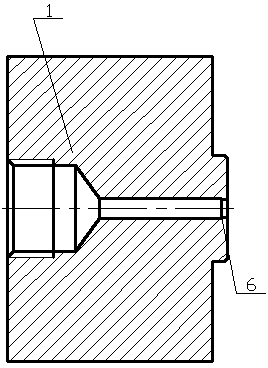

[0024] Such as figure 2 , the inner diameter of the swirl body 1 and the swirl core 2 is 6.5 mm, the length is 40 mm, the inner diameter of the step 6 is 5.7 mm, and the length is 2 mm.

[0025] Such as image 3 , the helix angle of the swirl core 2 is β=27°, and the maximum length can be taken as a lead L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com