Rotary tube pump

A coil and tube pump technology, applied in the field of momentum impurity pumps, can solve problems such as easy blockage and affect the normal operation of equipment, and achieve the effects of easy manufacturing, low maintenance cost, and long maintenance-free time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

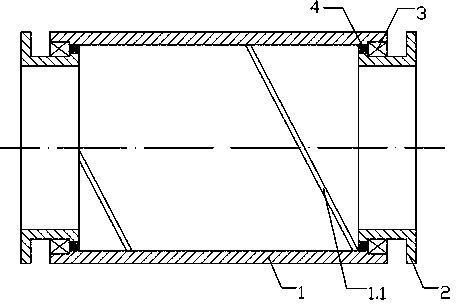

[0011] Below in conjunction with accompanying drawing, the present invention will be further described:

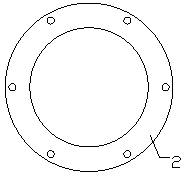

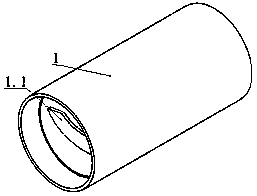

[0012] Referring to the accompanying drawings, the coil pump is mainly equipped with coil 1, flange 2, bearing 3, and seal 4, and the inner wall of the coil is provided with blades 1.1; Driven to rotate, during the process of passing through the coil cavity, the fluid gains acceleration under the thrust of the blades on the inner wall of the coil, and accelerates out of the pump body.

[0013] Although this invention was demonstrated in detail using the specific form, it is clear for those skilled in the art that various changes can be made without deviating from the intent and range of this invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com