High-performance regulating valve

A high-performance technology for regulating valves, applied in valve details, valve device, valve shell structure, etc., which can solve the problems of troublesome installation and disassembly, and easy to freeze at the connection, so as to achieve simple operation, improve practicability, and improve sealing performance. and the effect of frost resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

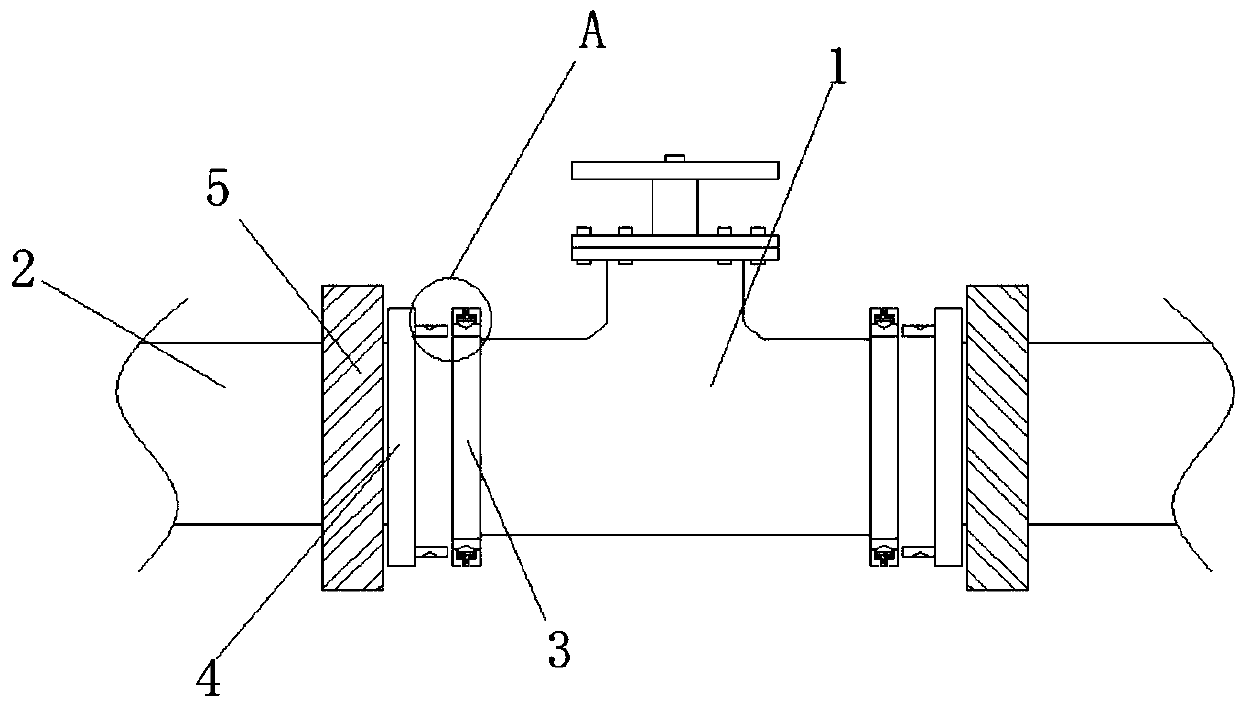

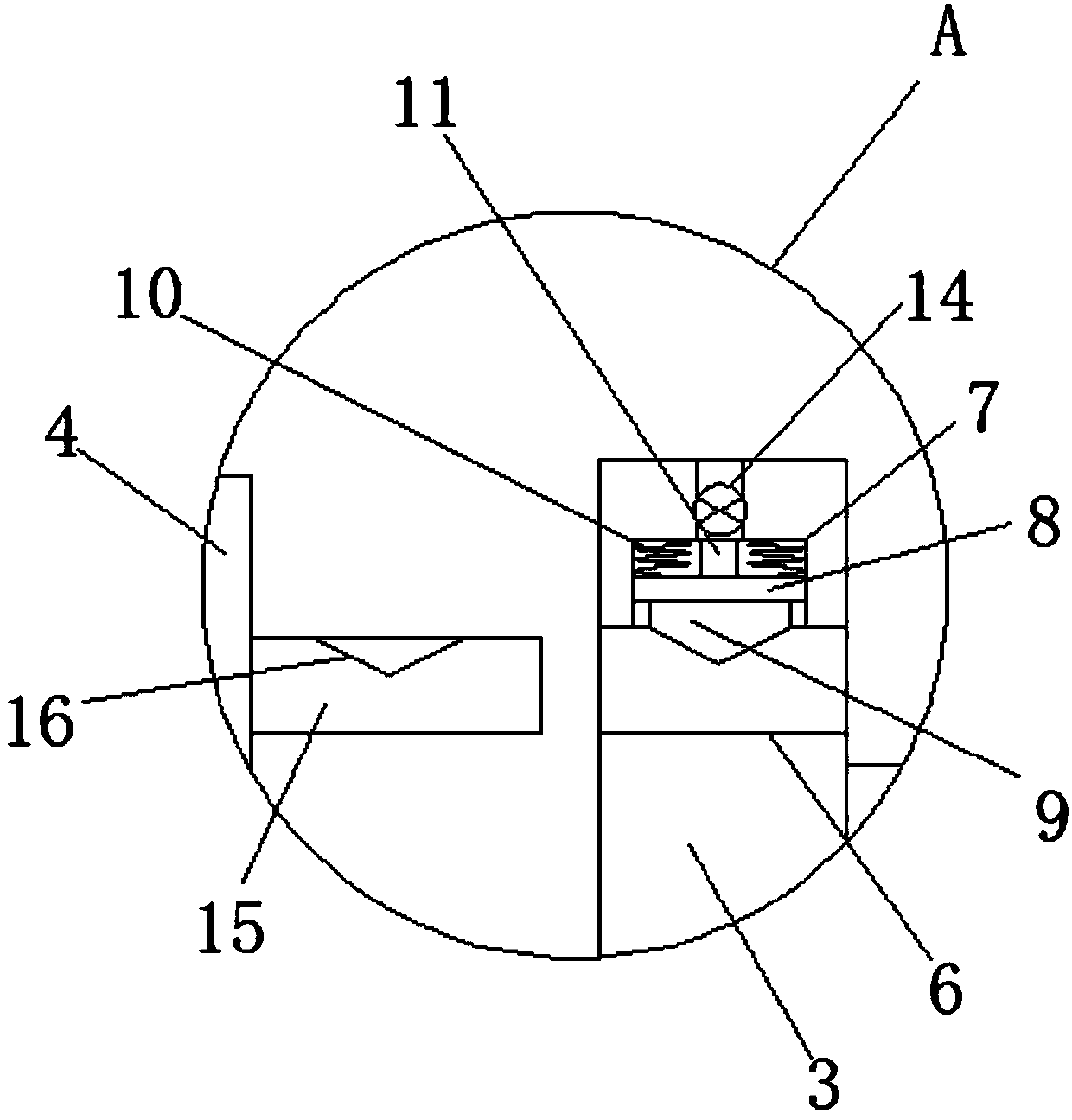

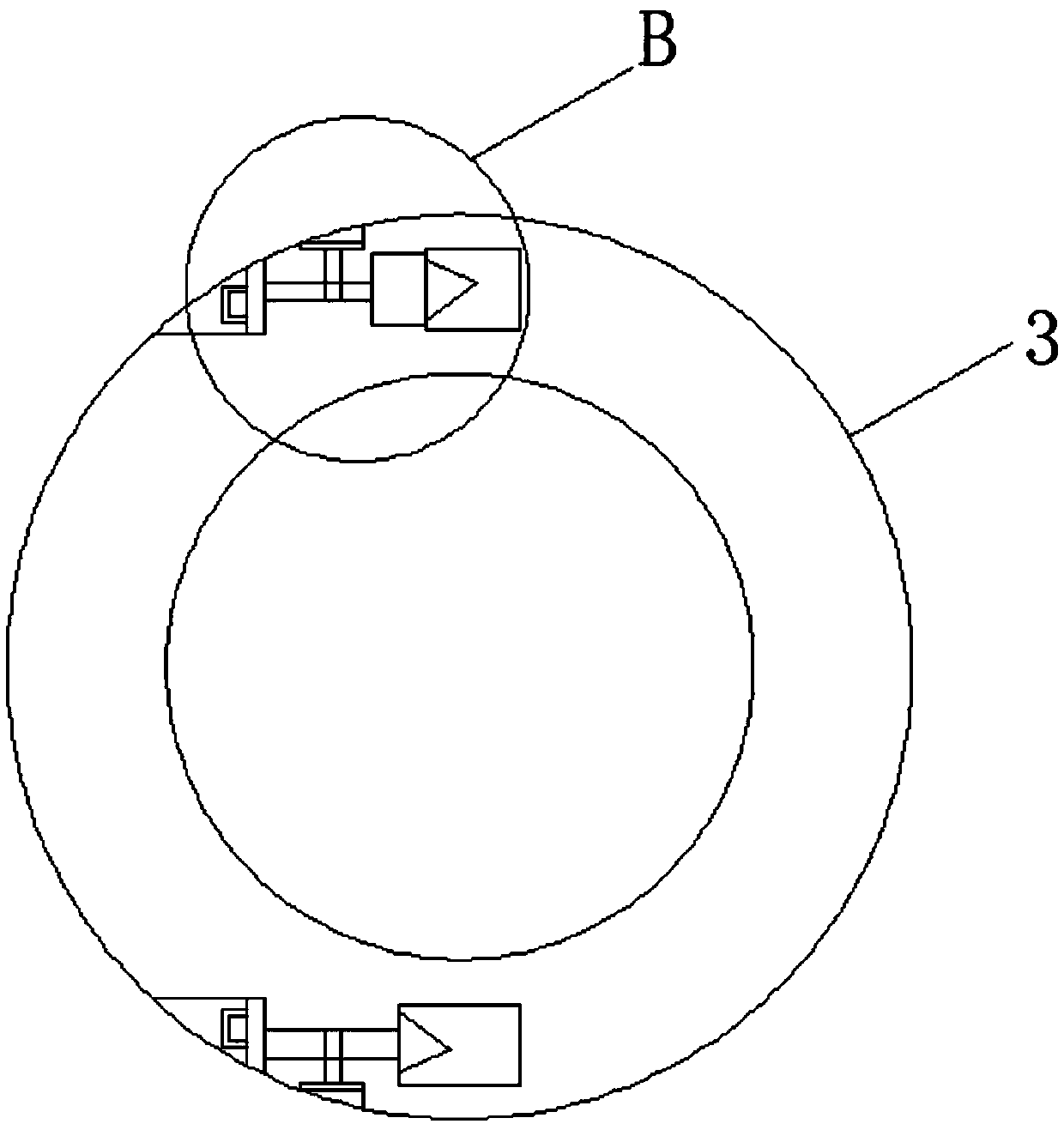

[0025] Embodiment: When installing the valve body 1 and the pipeline 2, by moving the pipeline 2, the pipeline 2 drives the second annular plate 4 to move, and the second annular plate 4 drives the limiting plate 15 to enter the first through hole 6, and the limiting plate When 15 enters the first through hole 6, squeeze the tapered surface of the fixing plate 9, so that the fixing plate 9 enters the first groove 7, until the fixing plate 9 is under the elastic force of the spring 10 and the limit plate 15 side wall is opened. The bit groove 16 is clamped and set, and finally the latch 14 is inserted to fix the position of the fixed plate 9, and then the sealing sleeve 15 is moved to make the sealing ring 18 tightly fitted on the joint of the first annular plate 3 and the second annular plate 4 , improved sealing, when it is disassembled, move the sealing sleeve 15, then take out the latch 14, pull the handle 13, the handle 13 drives the push plate 12, the push plate 12 drives ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com