Novel self-cooling electrode applied to industrial burner

A burner and self-cooling technology, which is applied in the direction of combustion ignition, combustion method, lighting and heating equipment, etc., can solve problems such as safety hazards, lower ignition success rate, electrode wire stress deformation, etc., to improve service life, protect equipment and people, the effect of good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

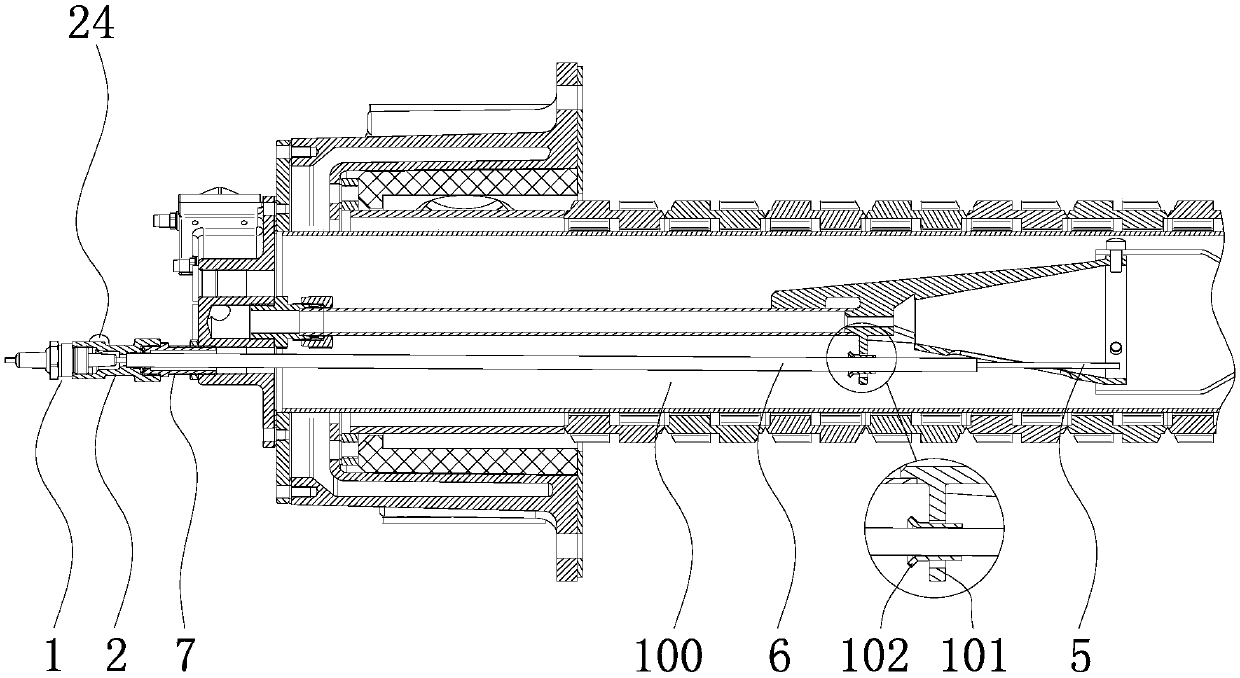

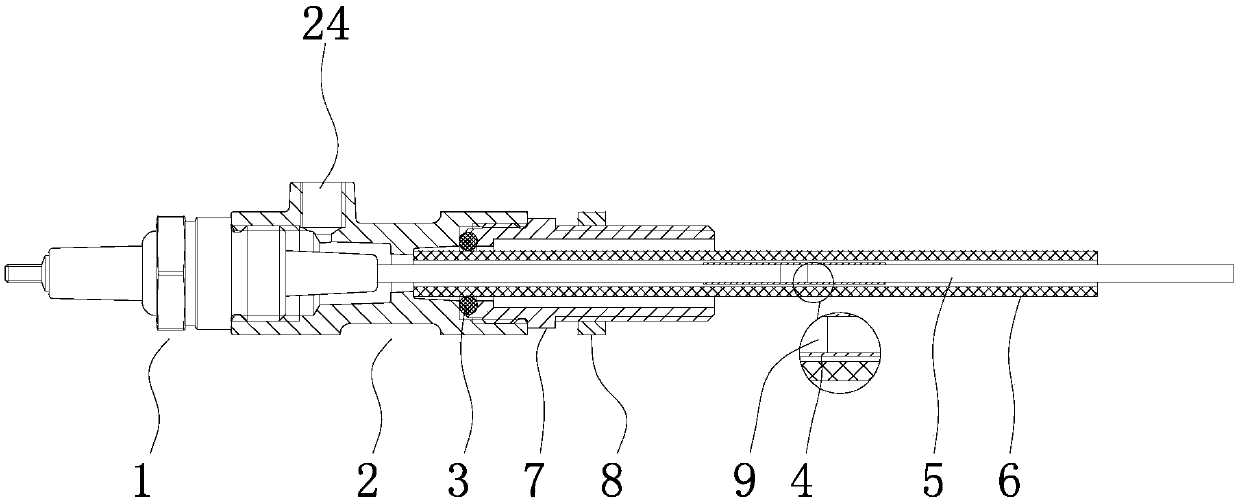

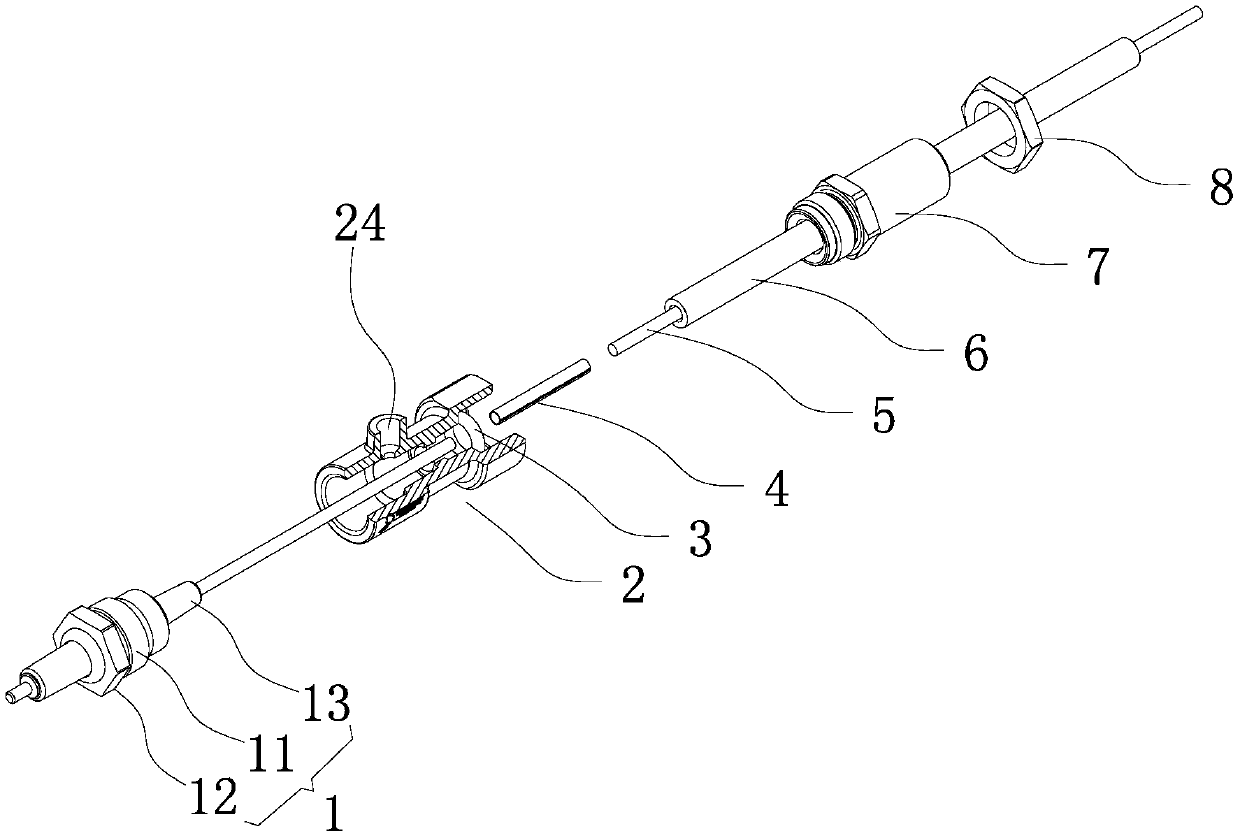

[0024] refer to Figure 1~6 , a novel self-cooling electrode applied to industrial burners, including an electrode and a burner for installing the electrode. Further, the electrode includes an electrode head 1 , an electrode shell 2 , an O-ring 3 , an electrode ferrule 4 , an extended electrode wire 5 , a ceramic tube 6 , an adapter 7 and an adjustment nut 8 . The electrode casing 2 is integrally formed by insulating materials, and the electrode casing 2 includes an installation cavity I21, an installation cavity II22, and a channel 23 for connecting the installation cavity I21 and the installation cavity II22; the above-mentioned installation cavity I21, inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com