Ultrasonic gas meter

A gas meter and ultrasonic technology, applied in the direction of measuring devices, instruments, measuring flow/mass flow, etc., can solve the problems of gas equipment unable to use gas, pipeline blockage, and inability to discharge, so as to ensure effective gas chamber space and reduce pressure Loss value, effect of preventing inaccurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

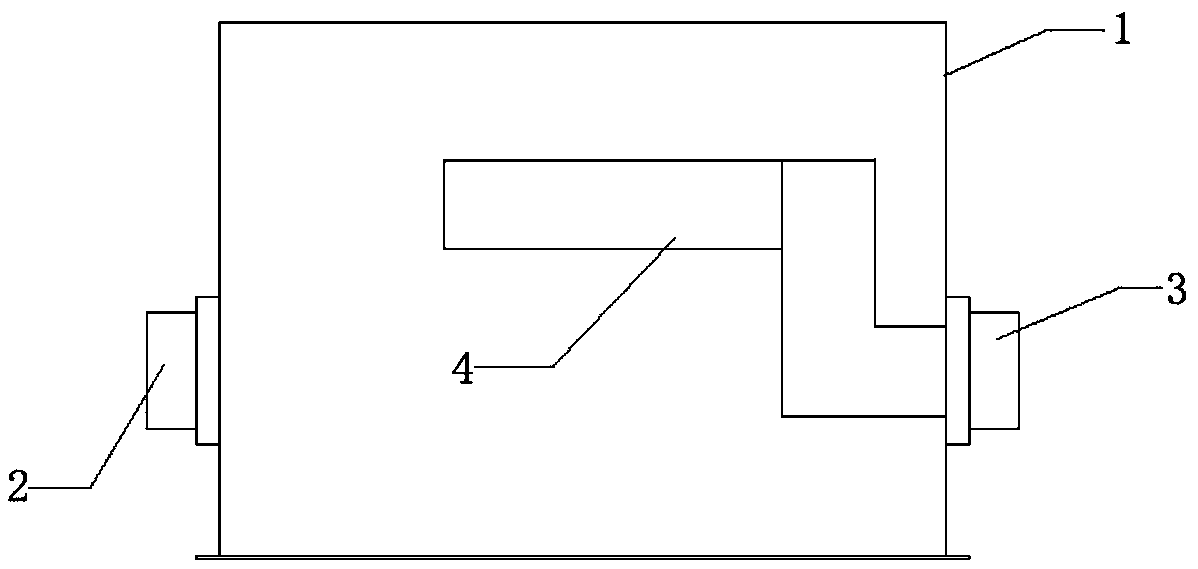

[0027] Such as figure 1 Shown is a schematic structural diagram of an ultrasonic gas meter, which includes a housing 1 , an air inlet 2 , an air outlet 3 , and a metering module 4 . The air inlet 2 and the air outlet 3 are respectively connected to existing gas pipelines.

[0028] The air inlet 2 is set on the side of the housing 1. The location of the air inlet 2 in this device breaks the inherent thinking of the structure of the air inlet 2 and the air outlet 3 in the structure of the traditional ultrasonic gas meter, and the air inlet 2 is set on the The side of the housing 1 can effectively prevent the water in the pipeline from flowing into the housing 1 from the air inlet 2, and at the same time, prevent water or other liquids from being artificially poured into the housing 1 from the air inlet 2, which will damage the metering Module 4 measurements.

[0029] The metering module 4 is arranged in the casing 1, and the metering module 4 is composed of a transducer, and t...

Embodiment 2

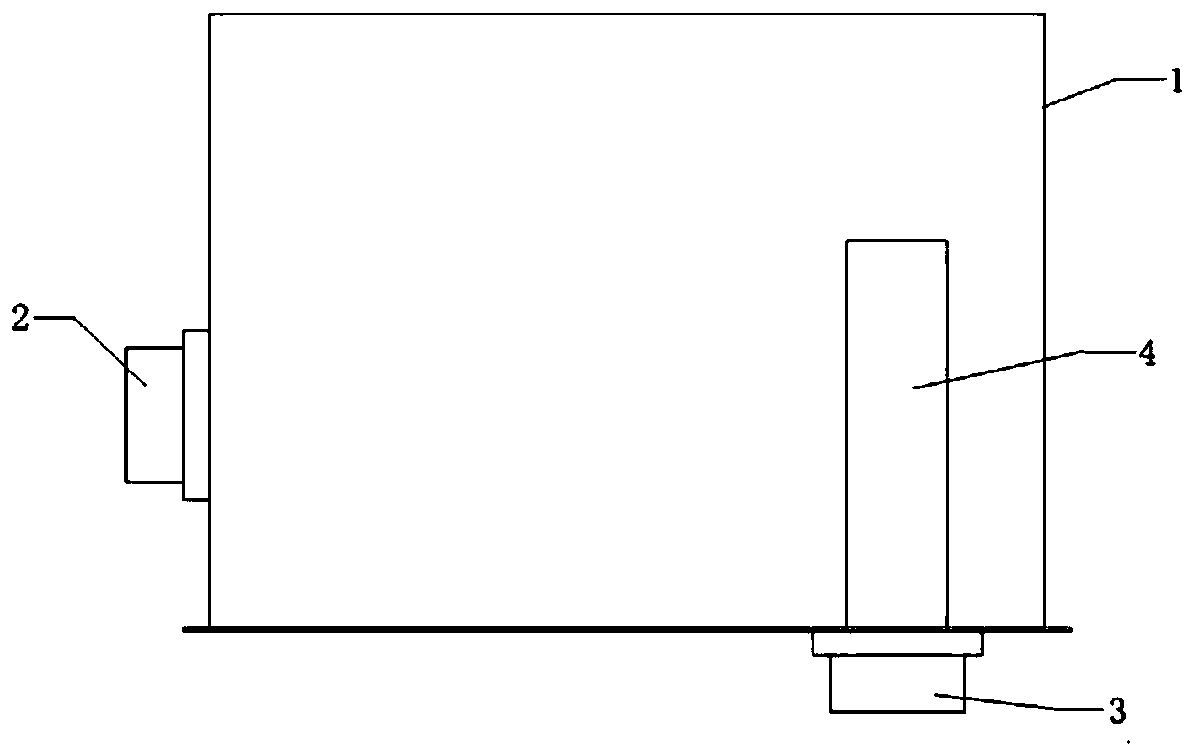

[0037] Such as figure 2 Shown: is an ultrasonic gas meter including a housing 1, a metering module 4, the metering module 4 is set in the housing 1, the housing 1 is provided with an air inlet 2 and an air outlet 3, an air inlet 2 and an air outlet 3 Connect the existing gas pipelines respectively. The metering module 4 is arranged in the casing 1, and the metering module 4 is composed of a transducer, and the transducer is composed of one or more sets of ultrasonic probes and air passages. After the gas enters the casing 1 from the air inlet 2, it flows A stabilized air chamber is formed inside, and then the air is fed from the inlet port of the metering module 4, and the accurate flow rate can be obtained through the metering module 4. It is discharged from the gas outlet of the metering module 4 to the gas outlet 3.

[0038] The air inlet 2 is set on the side of the housing 1, and the location of the air inlet 2 is different from the traditional air inlet 2, breaking the...

Embodiment 3

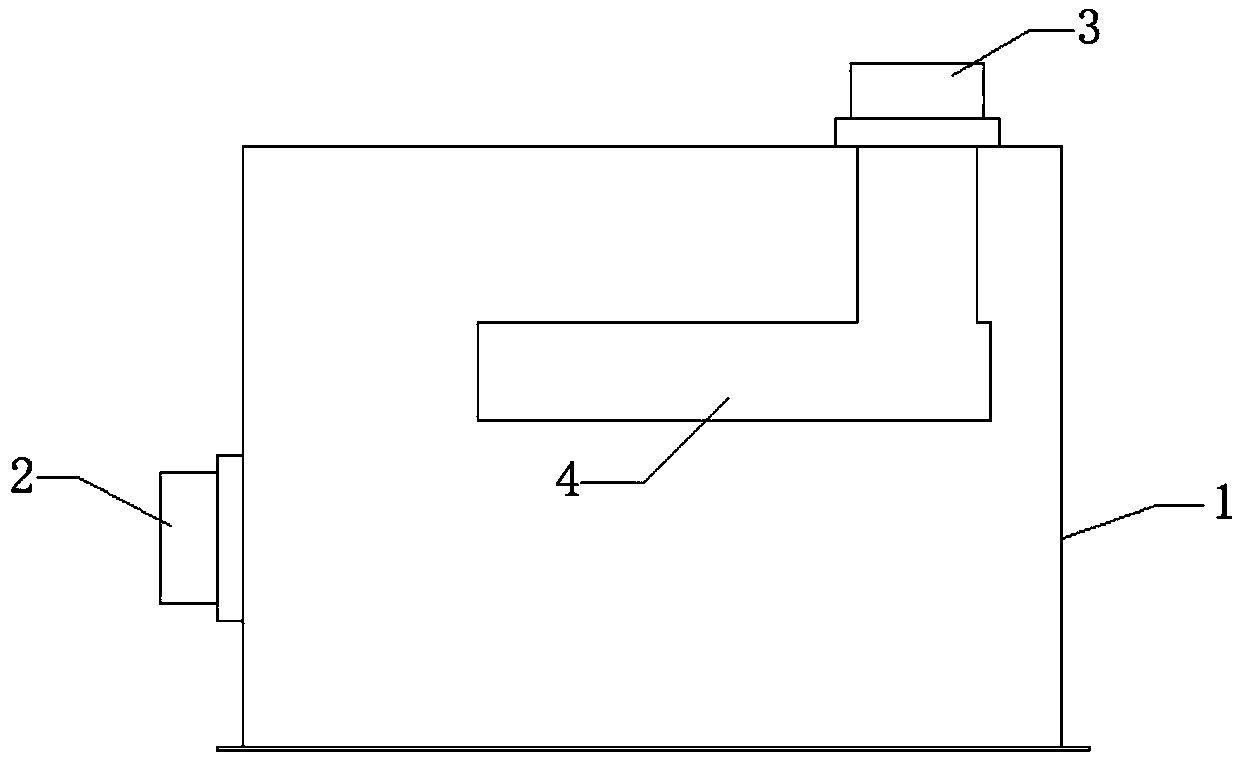

[0043] Such as image 3 As shown, an ultrasonic gas meter includes a housing 1 and a metering module 4, the metering module 4 is arranged in the housing 1, and the housing 1 is provided with an air inlet 2 and an air outlet 3, and an air inlet 2 and an air outlet 3 Connect the existing gas pipelines respectively.

[0044] The metering module 4 is composed of a transducer, and the transducer is composed of one or more sets of ultrasonic probes and air passages. After the gas enters the housing 1 from the air inlet 2, a stable pressure gas chamber is formed in the housing 1, and then The air is fed through the air inlet of the metering module 4 , and an accurate flow rate can be obtained through the metering module 4 . The air outlet of the metering module 4 is connected to the air outlet 3 of the casing 1 through an air outlet connecting pipe. The gas is then discharged from the gas outlet of the metering module 4 to the gas outlet 3 .

[0045] The air inlet 2 is set on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com