Experiment device for simulating mud-rock flow motion and experiment method thereof

An experimental device and debris flow technology, applied in fluid dynamics tests, measuring devices, material inspection products, etc., can solve the problems of not being able to effectively obtain the stress state of the debris flow base, achieve double selectivity, ensure repeatability, and have a reasonable concept Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

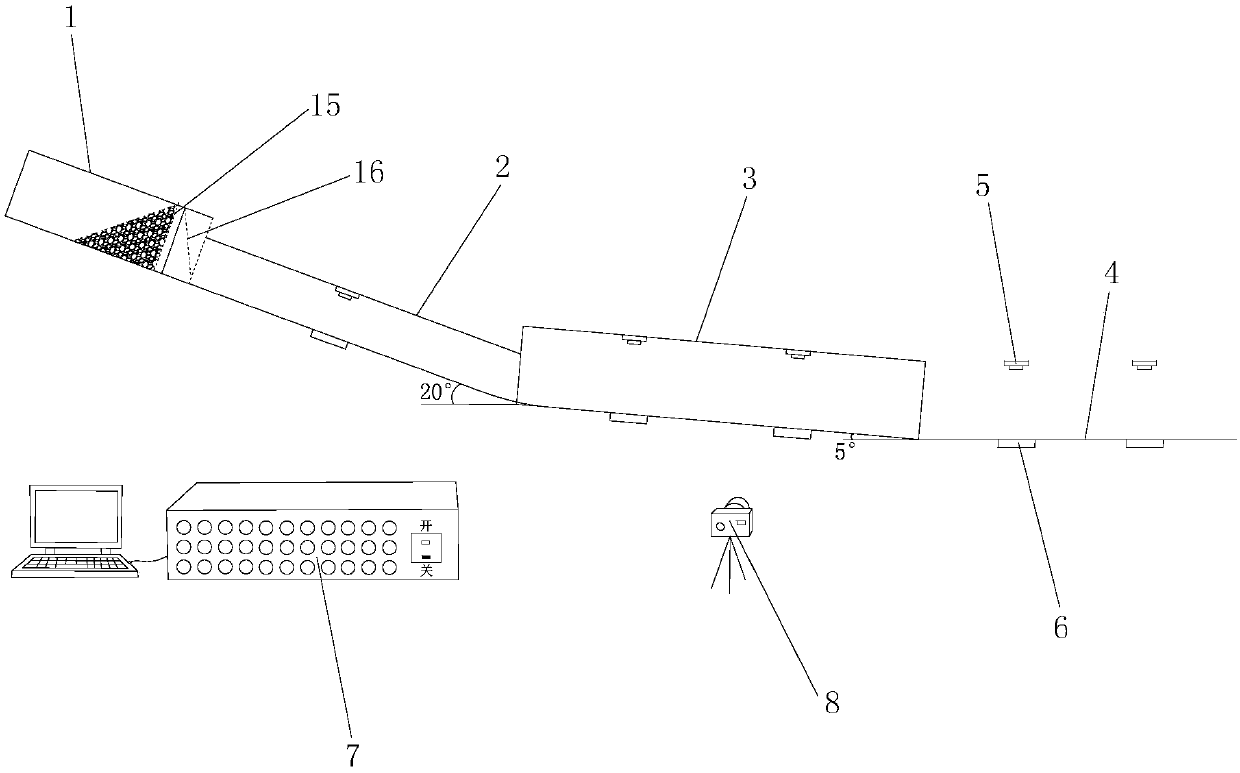

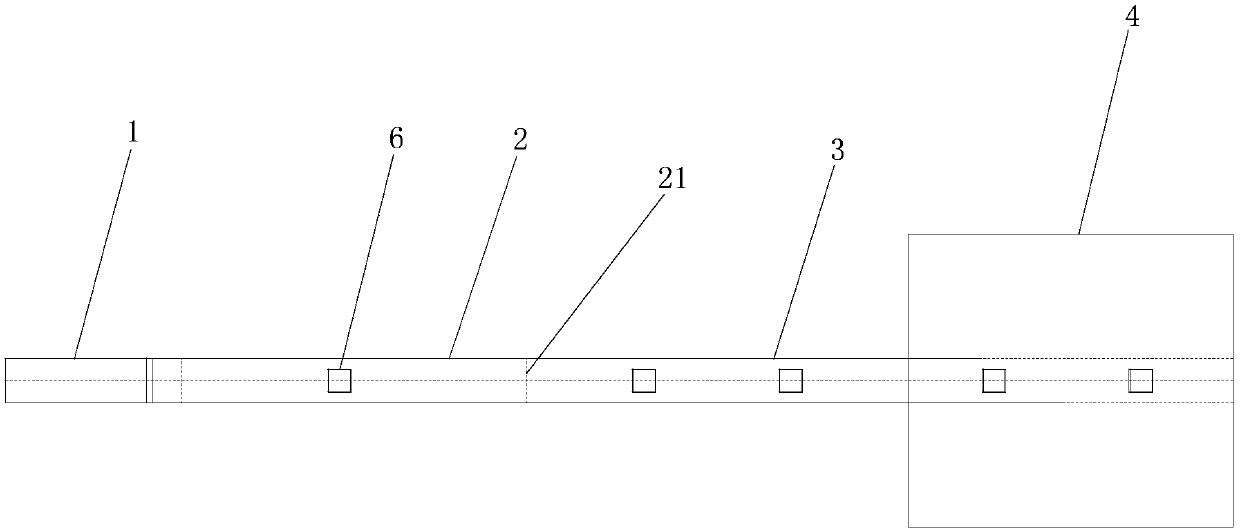

[0049] Such as Figures 1 to 7 As shown, the experimental device for simulating the movement of debris flow according to Embodiment 1 of the present invention includes a material box 1, a water tank, a stacking plate 4, an ultrasonic ranging sensor 5, a force sensor module 6, a synchronous data acquisition system 7 and a high-speed camera 8; The water tank is connected to one end of the water tank 1 and includes the water tank 2 of the acceleration movement section and the water tank 3 of the deceleration accumulation section.

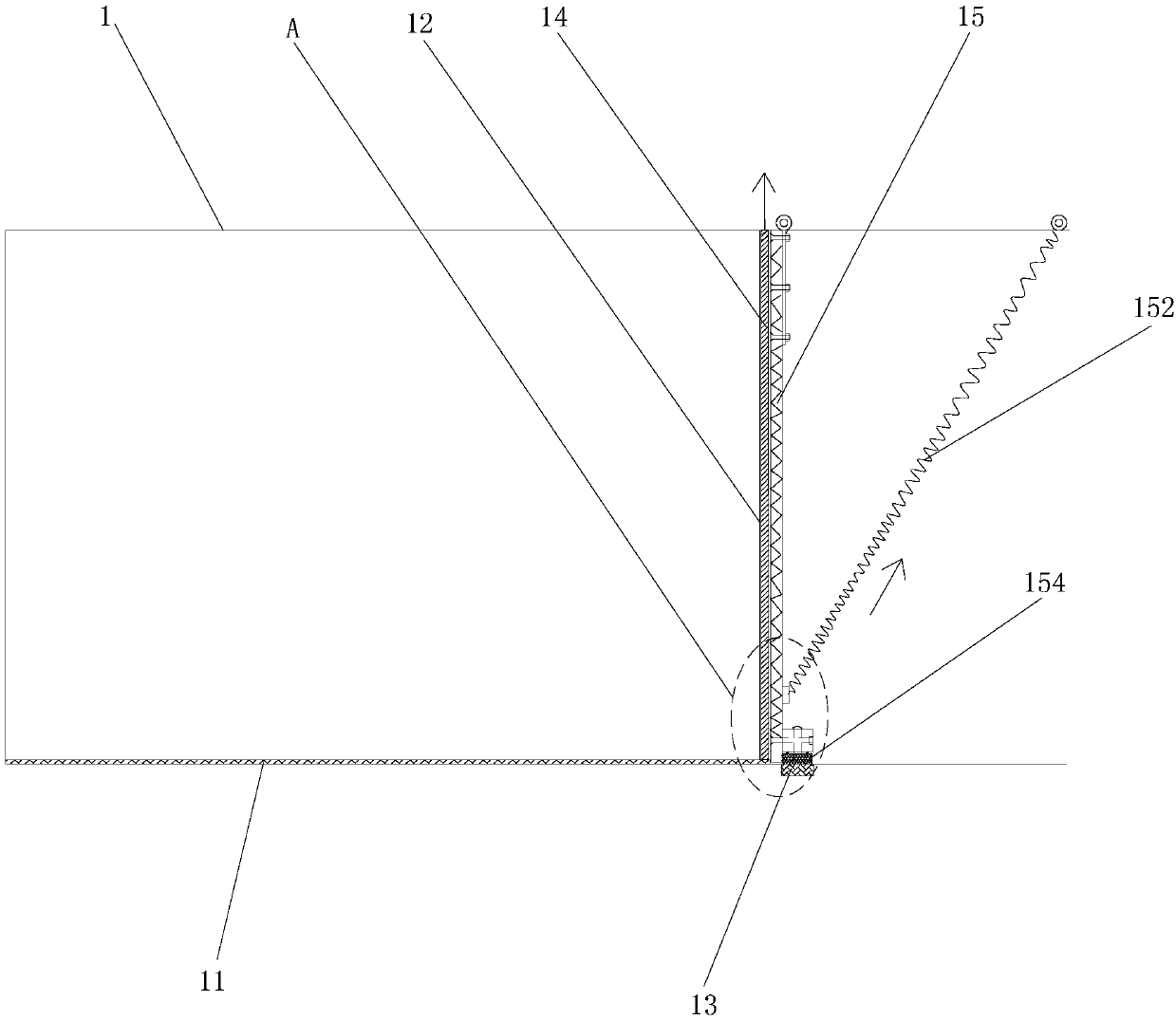

[0050] This hopper 1 is filled with debris flow materials, and its outer bottom is bonded with a plexiglass plate 11 with a thickness of about 5 mm, and the plexiglass plate 11 and the bottom of the hopper 1 form a step about 5 mm high; One end of the box 1 is connected to one end of the water tank 2 of the accelerated movement section through the water tank joint 12; the material box 1 is connected to the water tank 2 of the accelerated movement secti...

Embodiment 2

[0078] Such as Figure 8 As shown, the experimental device for simulating the interaction between debris flow and structures in Embodiment 2 of the present invention is based on Embodiment 1. A dam structure 9 is installed inside the water tank 3 in the deceleration accumulation section, and the load cell module 6 and the layout position of the ultrasonic ranging sensor 5 have been adjusted.

[0079] The concrete flow process of the experimental device for simulating mud-rock flow movement of embodiment 2 of the present invention comprises the steps almost identical with the step of simulating mud-rock flow movement in embodiment 1, just needs in the step (2) in embodiment 1 The selected position installs the dam body structure 9 through the screw holes reserved at the bottom of the water tank 2 of the acceleration movement section and the bottom of the water tank 3 of the deceleration accumulation section.

[0080]The present invention considers the characteristics of the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com