Microscopy and method for transferring perovskite nanowire and black phosphorus thin film composites

A thin-film composite material and nanowire technology, applied in microscopes, instruments, optics, etc., can solve problems such as inability to take pictures, fixed-point and directional transfer of difficult black phosphorus films, and poor compatibility, so as to avoid oxygen and water contact and meet the needs of sample transfer , the effect of improving the success rate of transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

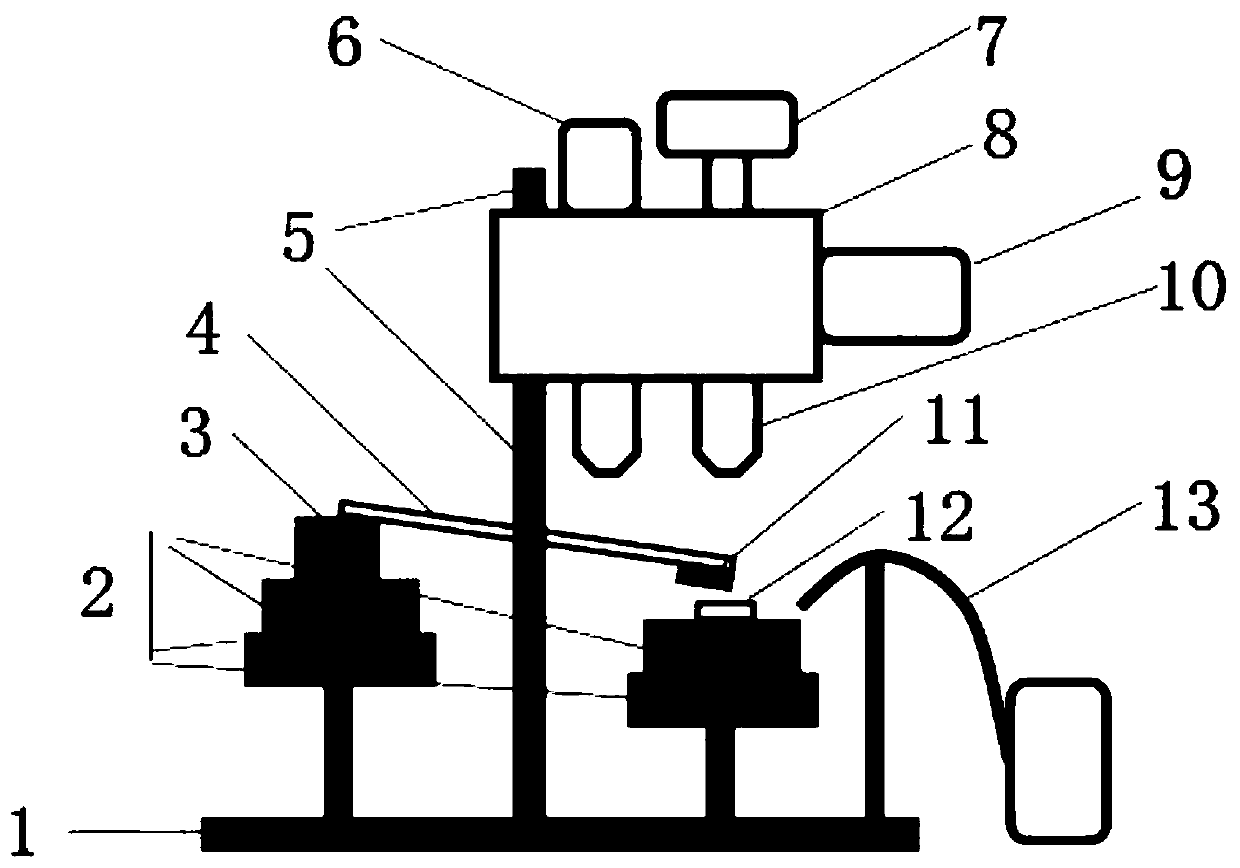

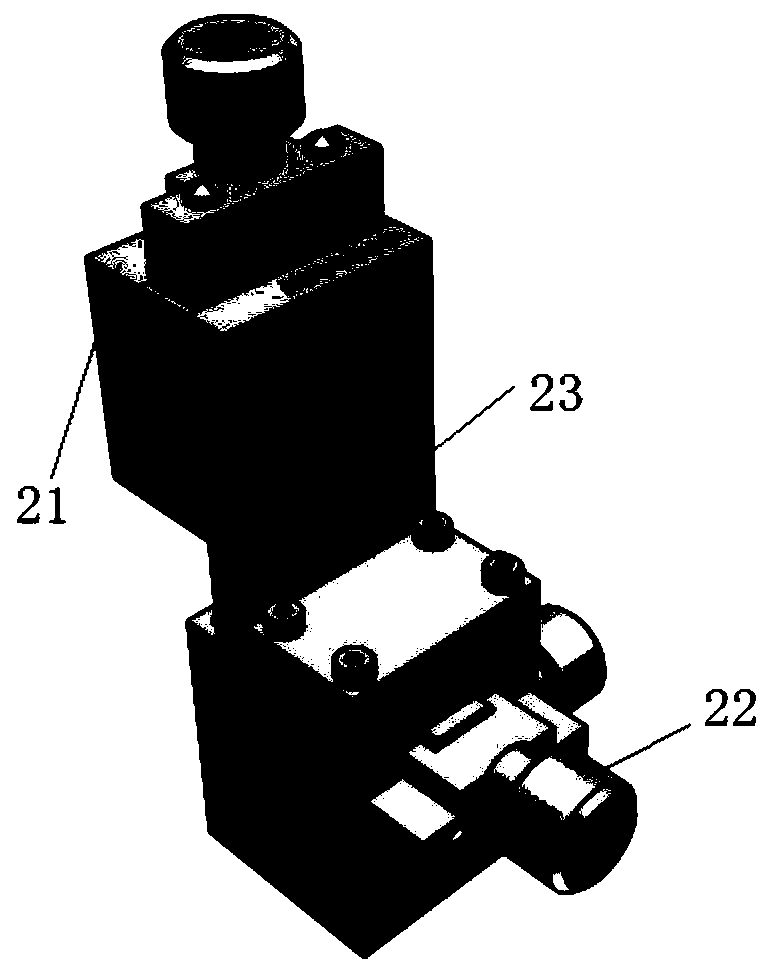

[0043] see figure 1 , the microscope of the embodiment of the present invention includes a base 1, and two three-dimensional translation stages 2 that can be adjusted in the X, Y, and Z directions are arranged on the base. For a schematic structural diagram of the three-dimensional translation stage, see figure 2, wherein on the stage in the Z-axis direction of the three-dimensional translation stage on the left, the glass cantilever 4 is fixed by the 360-degree horizontal rotation holder 3, and the optical microscope assembly is arranged on the pole 5 of the base. The optical microscope assembly of this embodiment includes Eyepiece 6, electronic camera 7, optical lens group 8, light source 9, objective lens 10, wherein, the pre-transfer sample is the perovskite nanowire of positive nucleation growth and the black phosphorus thin film prepared by mechanical stripping; Adhere with PDMS flexible substrate 11 Hold the pre-transferred sample that meets the requirements, and recor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com