A Deep Learning-Based Method for Detection and Measurement of Metal Sheet Defects

A defect detection and deep learning technology, applied in character and pattern recognition, image analysis, image enhancement, etc., to achieve the effect of wide application, avoiding missed detection and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

[0040] The invention provides a metal plate defect detection and measurement method based on deep learning, the method comprising the following steps:

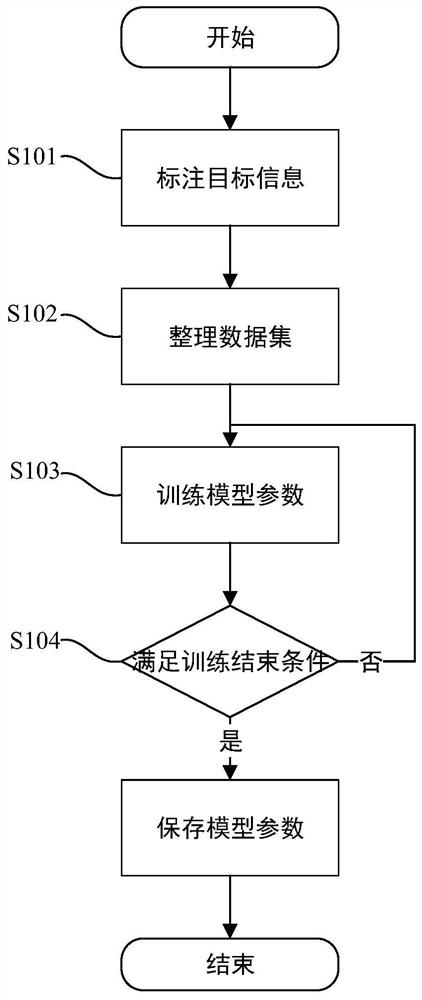

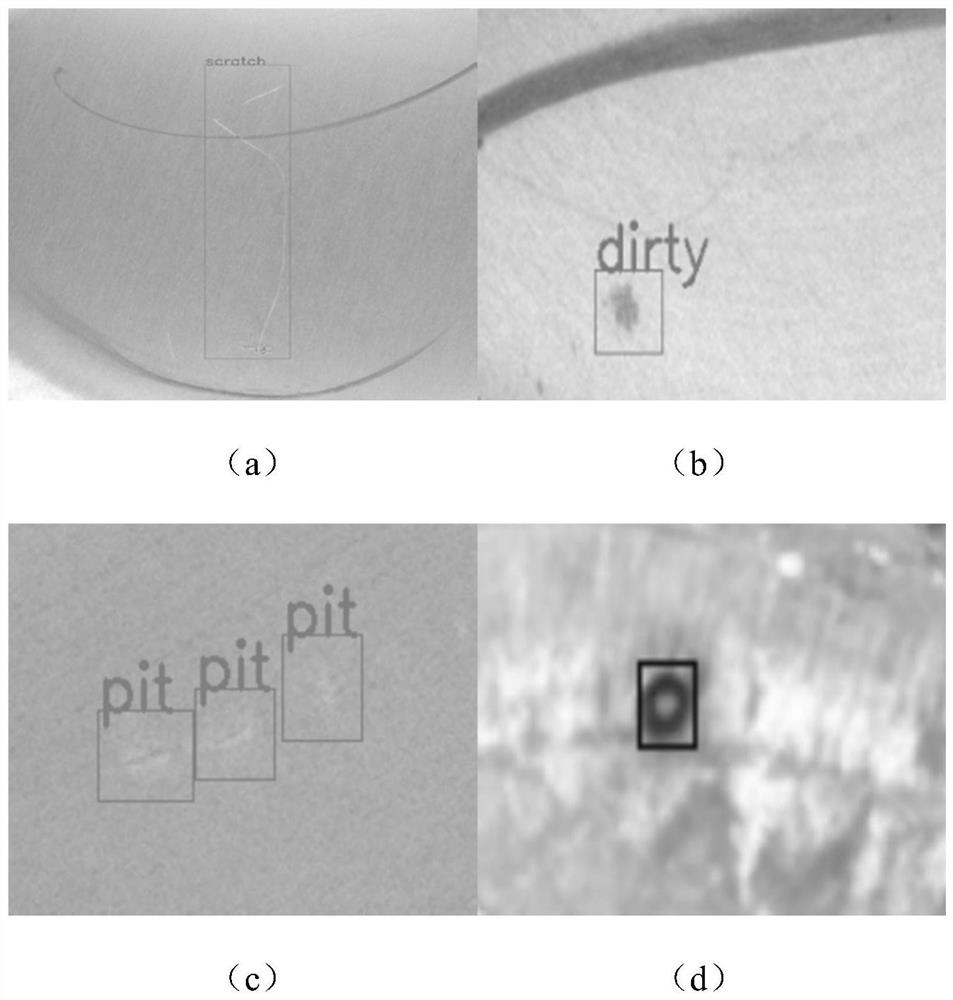

[0041] 1) Establish and train a multi-cascade defect detector based on deep learning target detection;

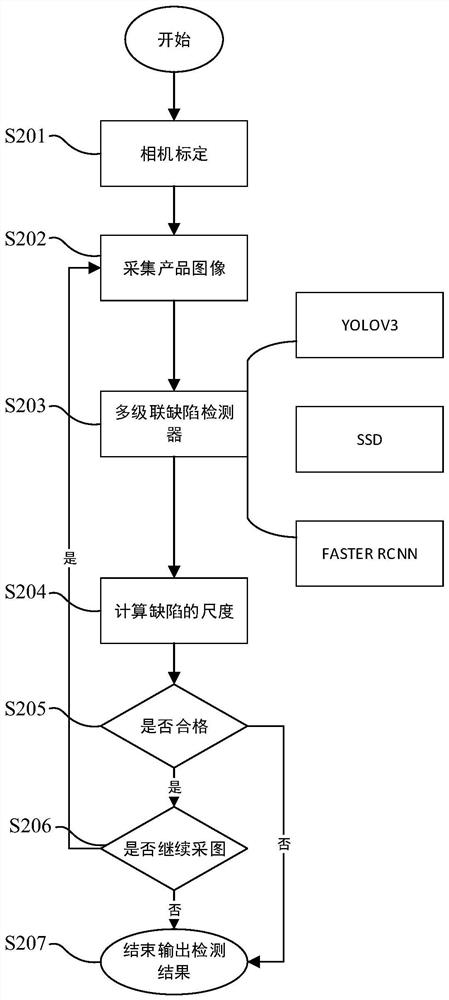

[0042] 2) using the multi-cascade defect detector to detect metal plate defects;

[0043] 3) When a defect is detected, the physical size of the defect is measured by a checkerboard calibration method.

[0044] The present invention adopts cascade detectors of multiple deep learning target detection algorithms, and the target det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com