High recharge rate lead-acid battery negative lead paste, battery negative plate and high recharge rate lead-acid battery

A lead-acid battery, negative lead paste technology, applied in lead-acid battery electrodes, lead-acid batteries, battery electrodes, etc., can solve the problems of insufficient recharge capacity, battery power loss, battery deep discharge, etc., and achieve good charging acceptance. , high recharge rate, long cycle life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

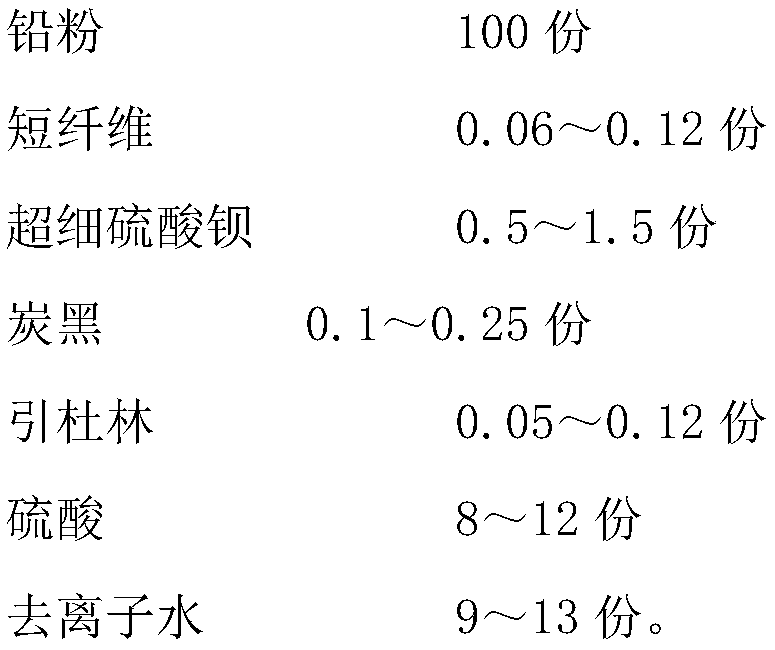

[0026] A negative lead paste for a lead-acid storage battery with a high recharge rate, comprising the following components in parts by weight:

[0027]

[0028] Wherein, lead powder is the lead powder that contains PbO, and the content of PbO is 72wt%; The length of short fiber is 3-4mm, and fineness is 0.5D; The specific surface area of carbon black is in 2000m 2 / g; the density of sulfuric acid is 1.35g / mL.

[0029] The method for preparing the negative plate of a lead-acid storage battery with a high recharge rate by utilizing the above-mentioned lead paste formula comprises the following steps:

[0030] S1: Mix short fiber, carbon black, and durin according to the formula requirements to make a negative electrode auxiliary material package.

[0031] S2: Add the negative electrode auxiliary material package into the paste mixing machine, and then add the lead powder into the paste mixing machine according to the proportion required by the formula and dry stir for 100...

Embodiment 2

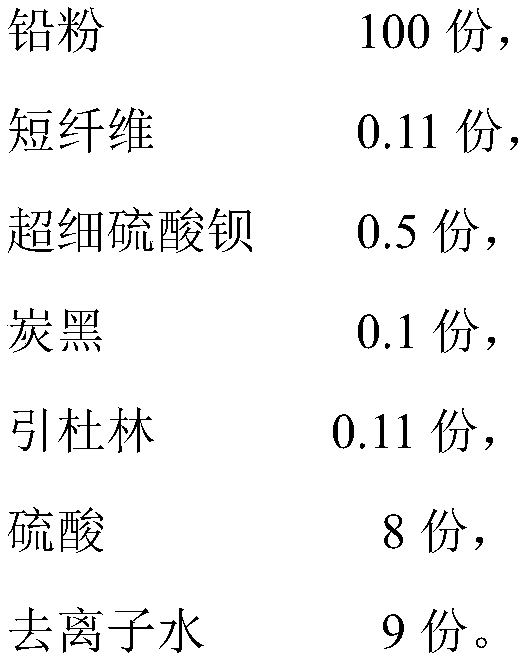

[0037] A negative lead paste for a lead-acid storage battery with a high recharge rate, comprising the following components in parts by weight:

[0038]

[0039] Wherein, lead powder is the lead powder that contains PbO, and the content of PbO is 76wt%; The length of short fiber is 3-4mm, and fineness is 1.5D; The specific surface area of carbon black is in 2500m 2 / g; the density of sulfuric acid is 1.32g / mL.

[0040] The method for preparing the negative plate of a lead-acid storage battery with a high recharge rate by utilizing the above-mentioned lead paste formula comprises the following steps:

[0041] S1: Mix short fiber, carbon black, and durin according to the formula requirements to make a negative electrode auxiliary material package.

[0042] S2: Add the negative electrode auxiliary material package into the paste mixing machine, and then add the lead powder into the paste mixing machine according to the proportion required by the formula and dry stir for 140...

Embodiment 3

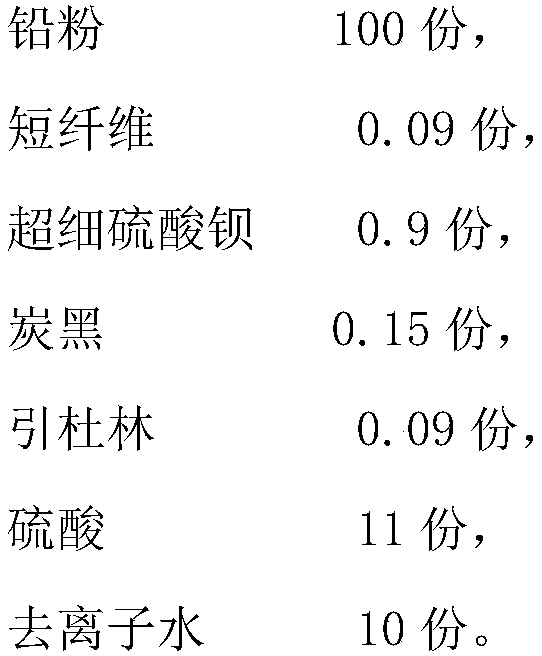

[0048] A negative lead paste for a lead-acid storage battery with a high recharge rate, comprising the following components in parts by weight:

[0049]

[0050] Wherein, lead powder is the lead powder that contains PbO, and the content of PbO is 80wt%; The length of short fiber is 3-4mm, and fineness is 0.8D; The specific surface area of carbon black is in 2300m 2 / g; the density of sulfuric acid is 1.38g / mL.

[0051] The method for preparing the negative plate of a lead-acid storage battery with a high recharge rate by utilizing the above-mentioned lead paste formula comprises the following steps:

[0052] S1: Mix short fiber, carbon black, and durin according to the formula requirements to make a negative electrode auxiliary material package.

[0053] S2: Add the negative electrode auxiliary material package into the paste mixing machine, and then add the lead powder into the paste mixing machine according to the proportion required by the formula and dry stir for 120...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com