Artificial synthetic resin production apparatus

A technology for synthetic resin and production equipment, which is applied in chemical/physical/physical-chemical stationary reactors, grain processing, chemical/physical/physical-chemical processes, etc. Large particles and other problems, to achieve the effect of increasing the rotation rate, preventing the precipitation of raw materials, and strengthening the stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

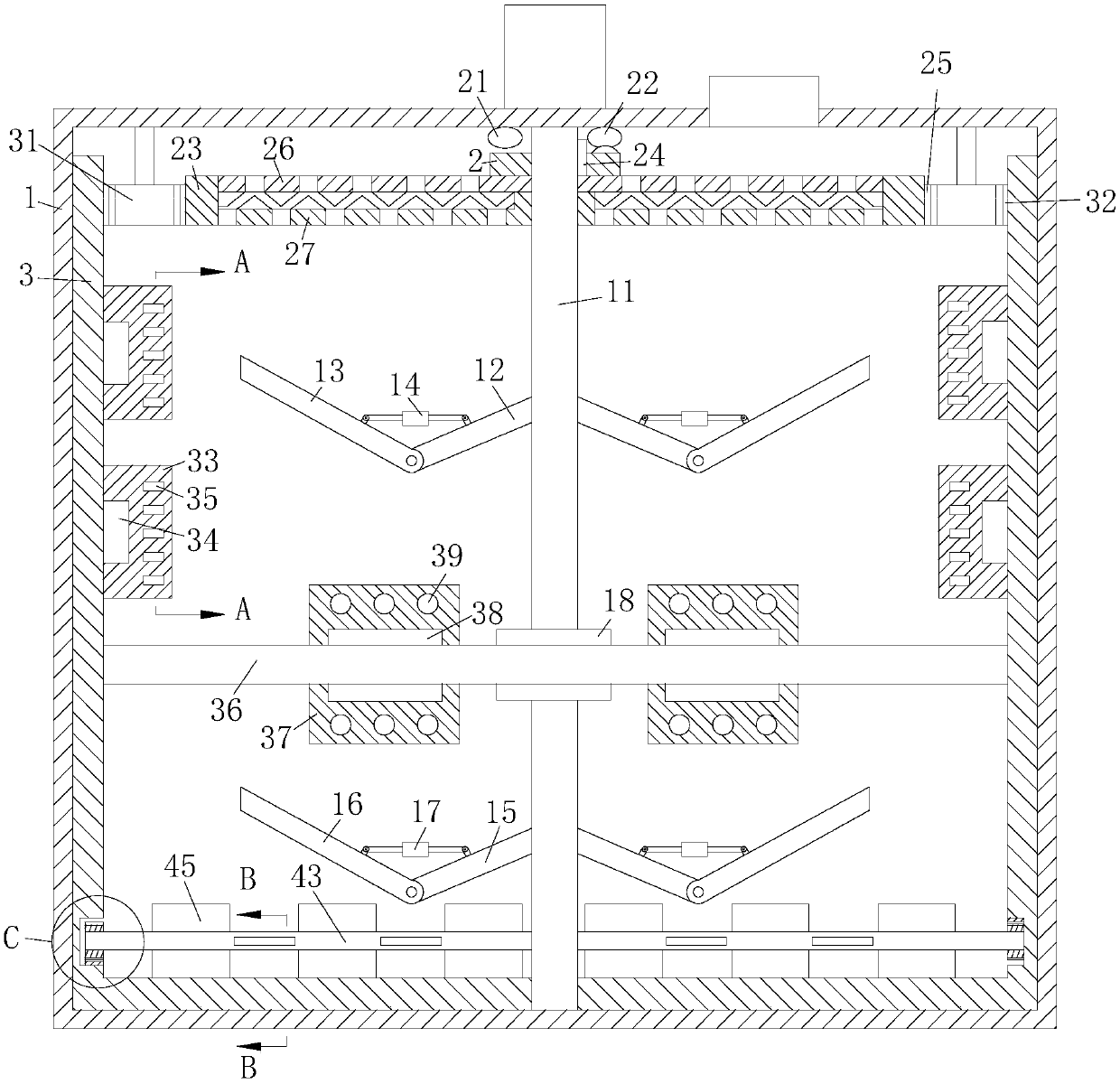

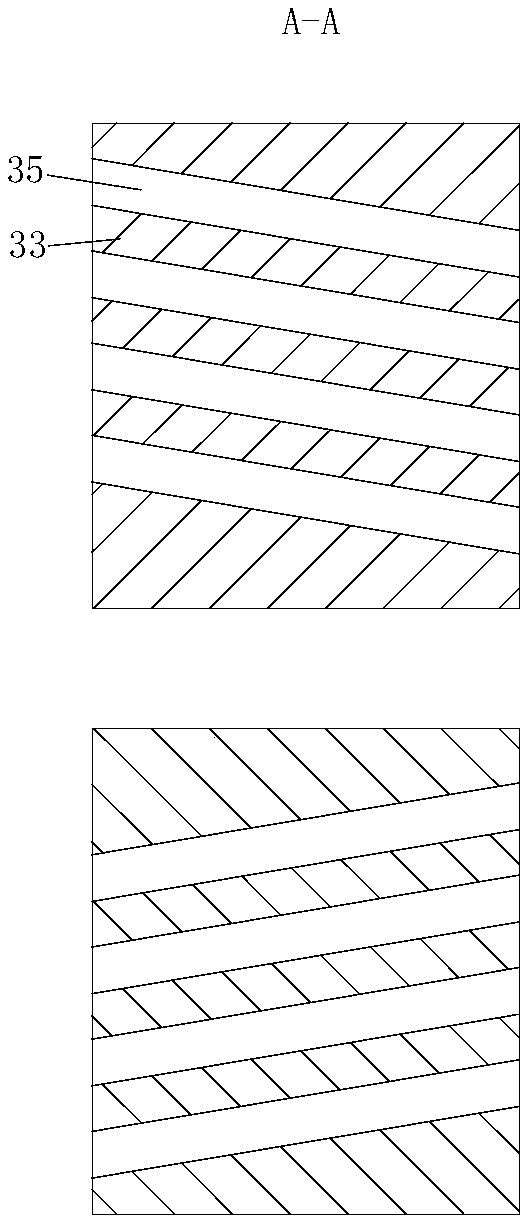

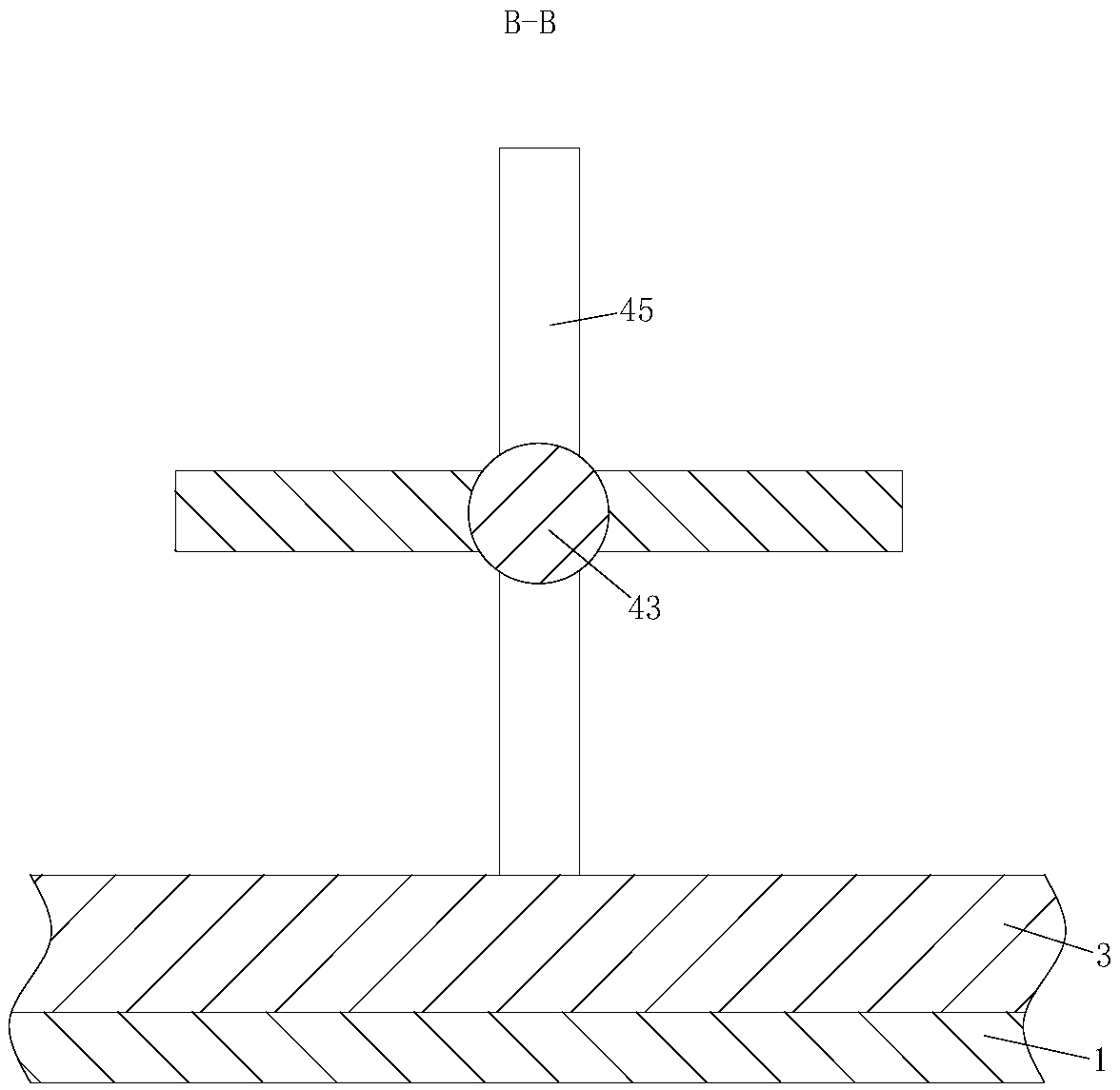

[0024] As an embodiment of the present invention, the frame body 1 is provided with a rotating plate 3; the rotating plate 3 is designed in a "U" shape and is rotatably connected to the inner wall of the frame body 1; the connection between the filter plate 23 and the rotating plate 3 There are evenly arranged first gears 31 between them; the filter plate 23 has a circular design, and convex teeth 25 are evenly arranged on the surface, and the convex teeth 25 mesh with the first gear 31; the surface of the rotating plate 3 is fixedly connected with a circular ring The first rack 32, the first rack 32 meshes with the first gear 31; the first gear 31 is fixed on the top inner wall of the frame body 1 through a fixed shaft; the inner wall of the rotating plate 3 is evenly arranged with a first heating plate 33; When working, the motor drives the filter plate 23 to rotate, and through the action of centrifugal force, the large particles on the surface of the filter plate 23 are dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com