Gluing equipment for transparent adhesive tape production

A technology of scotch tape and gluing, which is applied in coatings and devices for coating liquid on the surface, etc. It can solve the problems that the tape is easy to form wrinkles and affect the orderly progress of glue spraying and winding operations, so as to avoid adverse effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

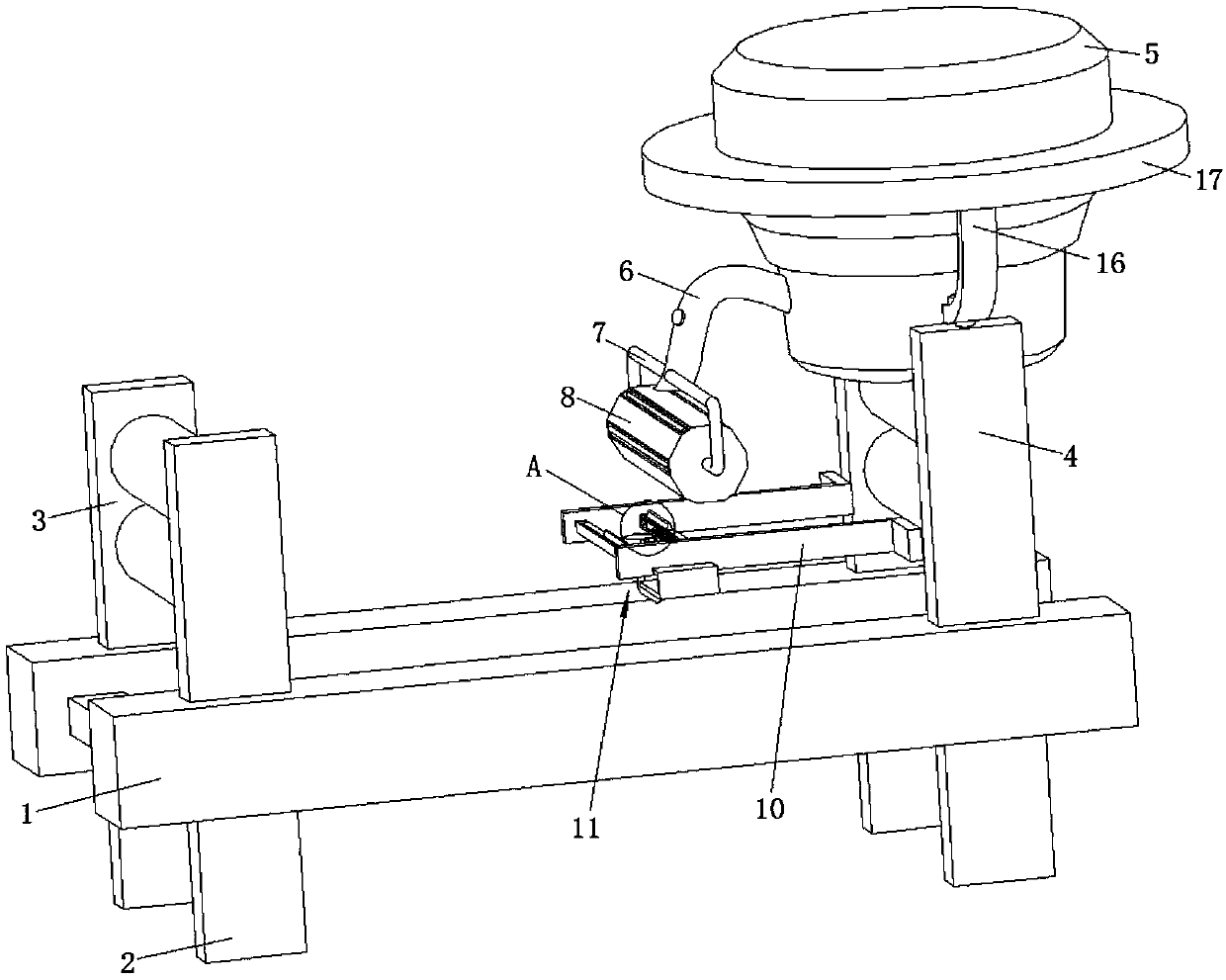

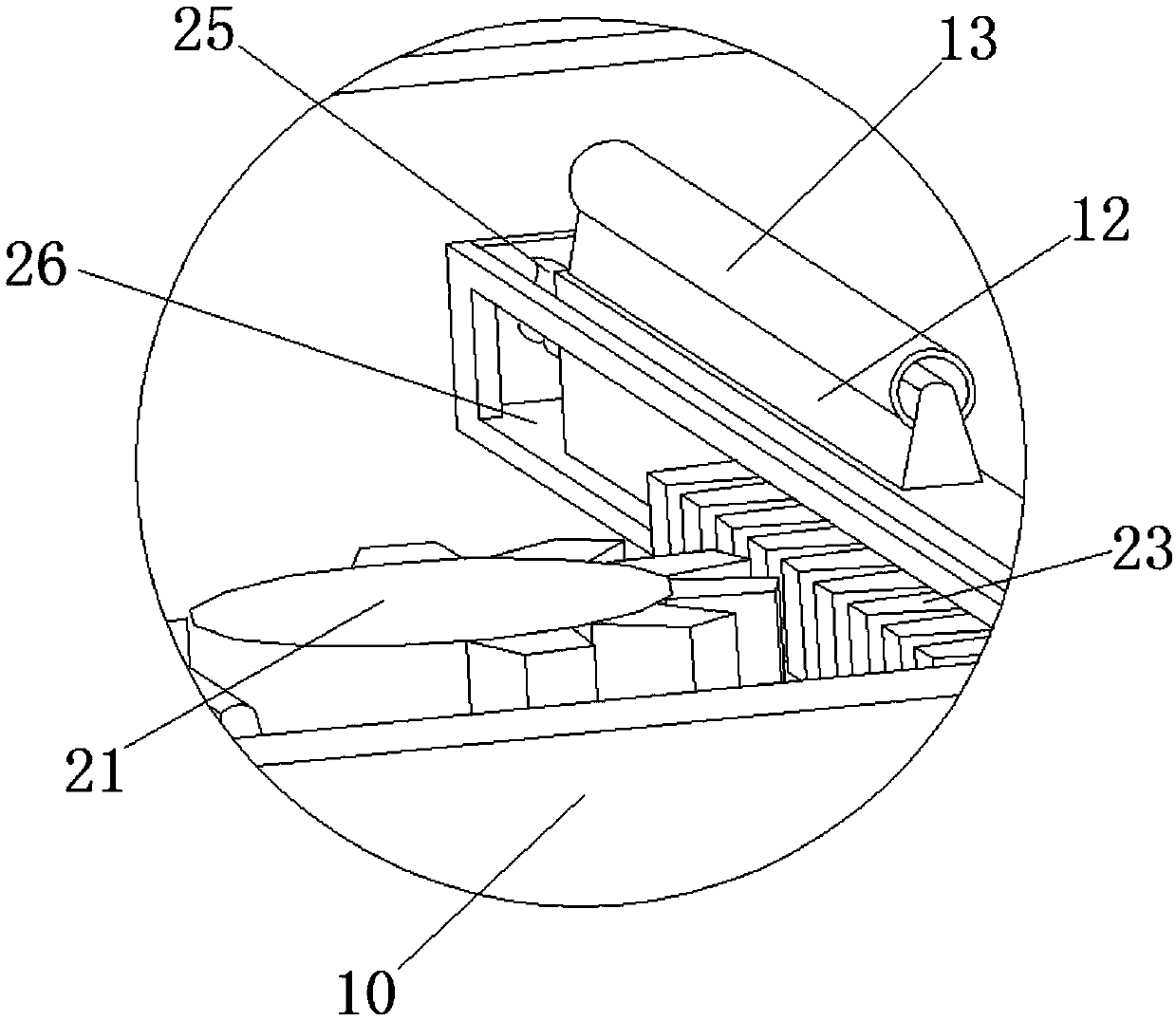

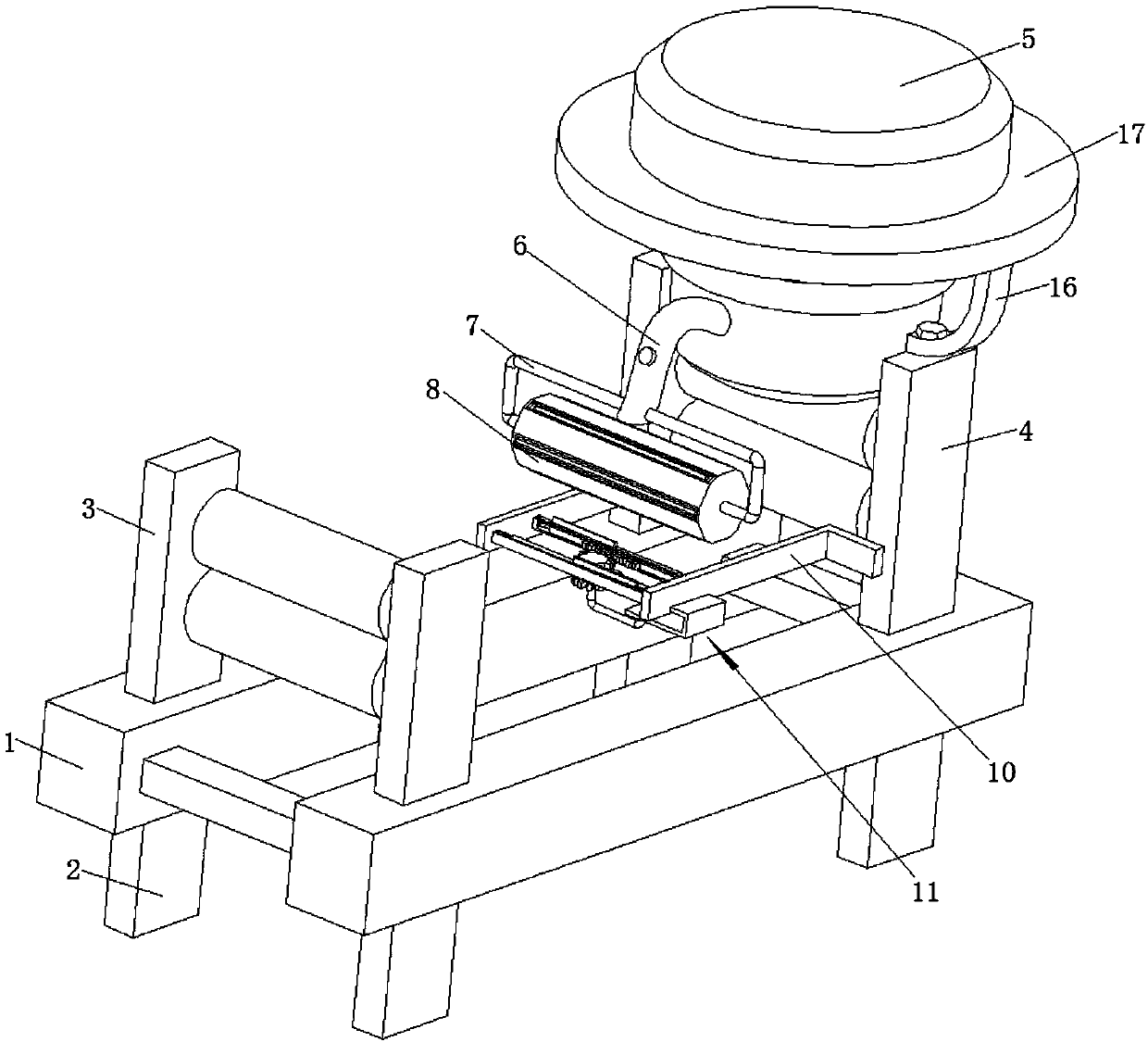

[0037] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 8, a kind of gluing equipment for scotch tape production, comprises support 1, support foot 2, and the top of support 1 is respectively connected with the first roller group 3, the second roller group 4, and the top of the second roller group 4 is connected with coating The rubber box 5 and the side wall of the bottom end of the glue box 5 are sealed and connected with a rubber tube 6, which is connected with a one-way valve. Roller 8, gluing roller 8 has a cavity inside, and the side wall of gluing roller 8 is provided with glue discharge hole 9; the side wall of the second roller shaft group 4 is connected with intermittent motion mechanism 11 through strut , the intermittent motion mechanism 11 is connected with a combing bar 12 that is arranged diagonally, and the top of the combing bar 12 is fixedly connected with a carding cover 13, and the carding cover 13 is specifically a glass cover. The first...

Embodiment 2

[0041] refer to Figure 7 , a kind of gluing equipment for the production of scotch tape, which is basically the same as that of Example 1, furthermore, the cross section of the gluing roller 8 is a regular hexagon, and the six edges of the gluing roller 8 have rounded corners Transitional design, and the glue discharge hole 9 is set on the rounded transition surface, and the rounded transition design on the six edges of the glue roller 8 is convenient for the glue roller 8 to softly contact with the tape and pass through the glue discharge hole 9 Apply spray glue to the tape.

Embodiment 3

[0043] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 7 , Figure 8 , a kind of gluing equipment for scotch tape production, comprises support 1, support foot 2, and the top of support 1 is respectively connected with the first roller group 3, the second roller group 4, and the top of the second roller group 4 is connected with coating The rubber box 5 and the side wall of the bottom end of the glue box 5 are sealed and connected with a rubber tube 6, which is connected with a one-way valve. Roller 8, gluing roller 8 has a cavity inside, and the side wall of gluing roller 8 is provided with glue discharge hole 9; the side wall of the second roller shaft group 4 is connected with intermittent motion mechanism 11 through strut , the intermittent motion mechanism 11 is connected with a combing bar 12 that is arranged diagonally, and the top of the combing bar 12 is fixedly connected with a carding cover 13, and the carding cover 13 is specificall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com