Press vulcanizer

A flat vulcanizing machine and flat plate technology, applied in the field of flat vulcanizing machines and their vulcanization, can solve the problems of low production efficiency and inability to fully utilize energy, and achieve the effects of convenient loading and unloading, novel structural design, and improved vulcanization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] At present, the flat vulcanizing machine is mainly used for vulcanizing flat belts (such as conveyor belts, transmission belts, referred to as flat belts), and belongs to hydraulic machinery. The main function of the flat vulcanizing machine is to provide the pressure and temperature required for vulcanization. The traditional vulcanizing machine has a relatively simple structure, low production efficiency, and cannot make full use of energy.

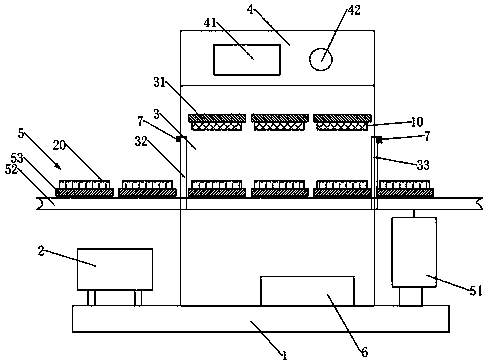

[0023] Such as figure 1 Shown is a flat vulcanizer, comprising a base 1, a hydraulic device 2, a vulcanization chamber 3, a control box 4, a conveying mechanism 5, a heating device 6, an upper heating plate 10 and a lower heating plate 20, the vulcanization chamber 3 and The control boxes 4 are all arranged on the machine base 1, and the control boxes 4 are arranged on the top outside of the vulcanization chamber 3. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com