Room temperature super-formability magnesium or magnesium alloy and manufacturing method thereof

A manufacturing method and formability technology are applied in the direction of improving process efficiency, etc., can solve the problems of poor formability of magnesium at room temperature, etc., and achieve the effects of low cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-20 and comparative example 1-5

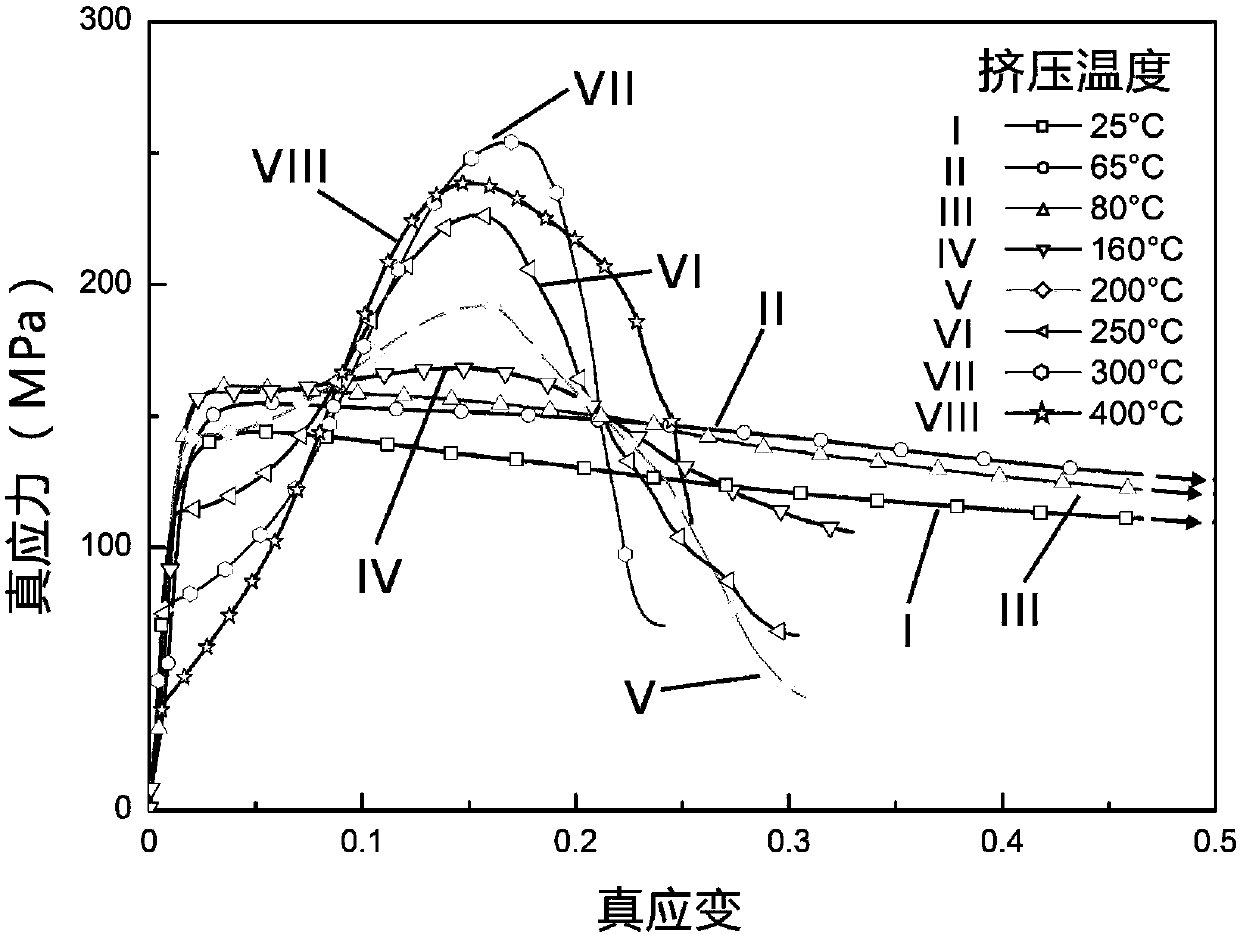

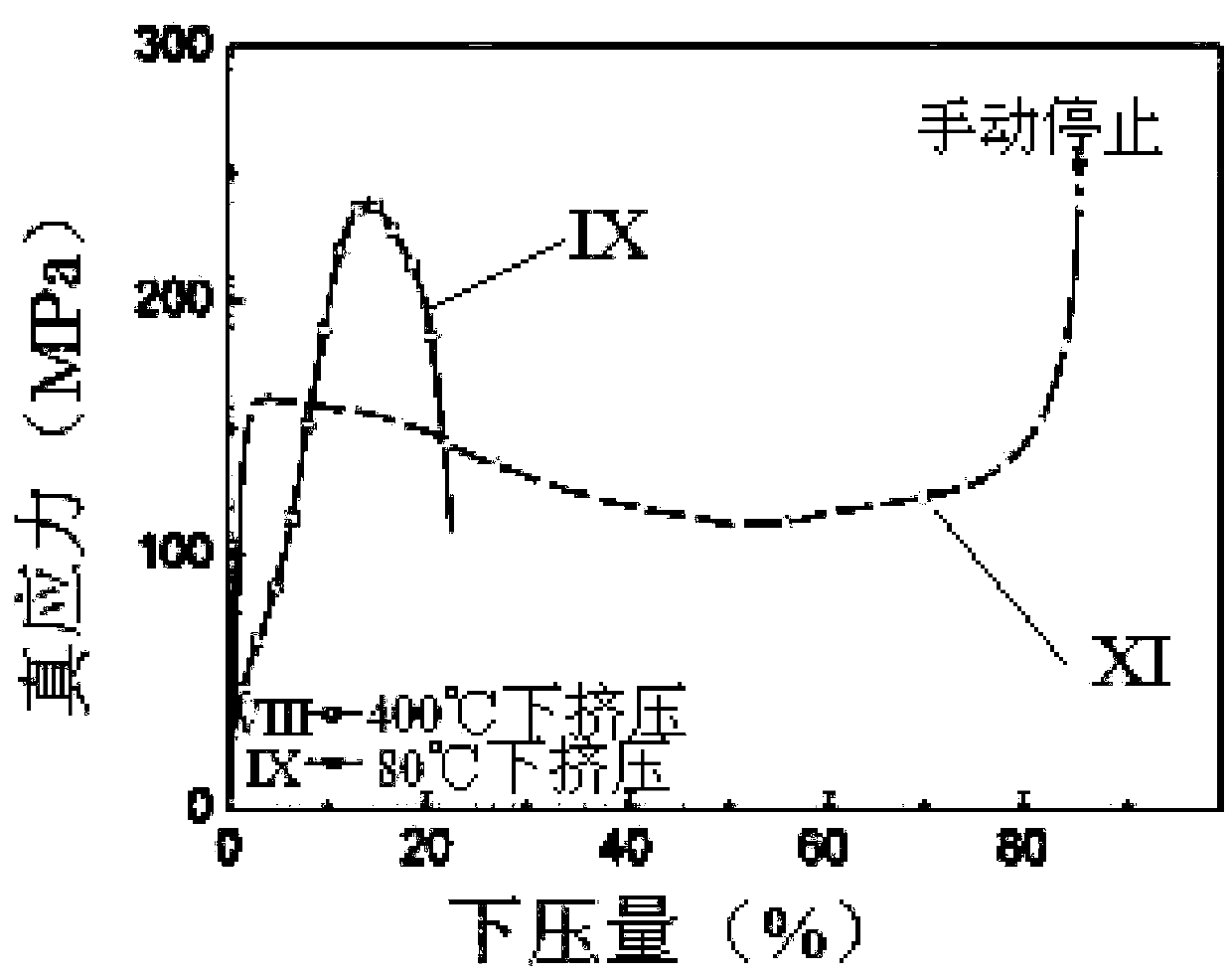

[0079] The manufacturing process of room temperature superformable magnesium profiles or magnesium alloy profiles includes the following steps: extruding raw materials at 20°C to 150°C, the extrusion ratio is 10:1 to 100:1, and the extrusion push rod speed is 0.05mm / s to 50mm / s to obtain the magnesium profile.

[0080] The manufacturing process of room temperature superformable magnesium plate or magnesium alloy plate includes steps:

[0081] (1) Extrude the raw material at 20℃~150℃, the extrusion ratio is 10:1~100:1, and the extrusion push rod speed is 0.05mm / s~50mm / s;

[0082] (2) Rolling into a magnesium sheet at 20°C to 100°C.

[0083] Wherein, the thickness of the magnesium plate is 0.3mm-4mm or 0.04mm-0.3mm.

[0084] Table 1 has listed the concrete process parameter in the manufacture method of the room temperature superformability magnesium of embodiment 1-12 or magnesium alloy.

[0085] Table 1.

[0086]

[0087]

[0088] Table 2 lists the grain sizes of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com