Environment-friendly road and method for preparing environment-friendly road paving blocks

A road and environmental protection technology, which is applied to pavement, roads, roads and other directions paved with prefabricated blocks. It can solve the problems that the water permeability of paving materials needs to be improved, and achieve the effects of increasing drainage performance, cooling, and high water absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] A preparation method of environmentally friendly road paving blocks includes the following steps:

[0050] S1 prefabricated slurry, spare;

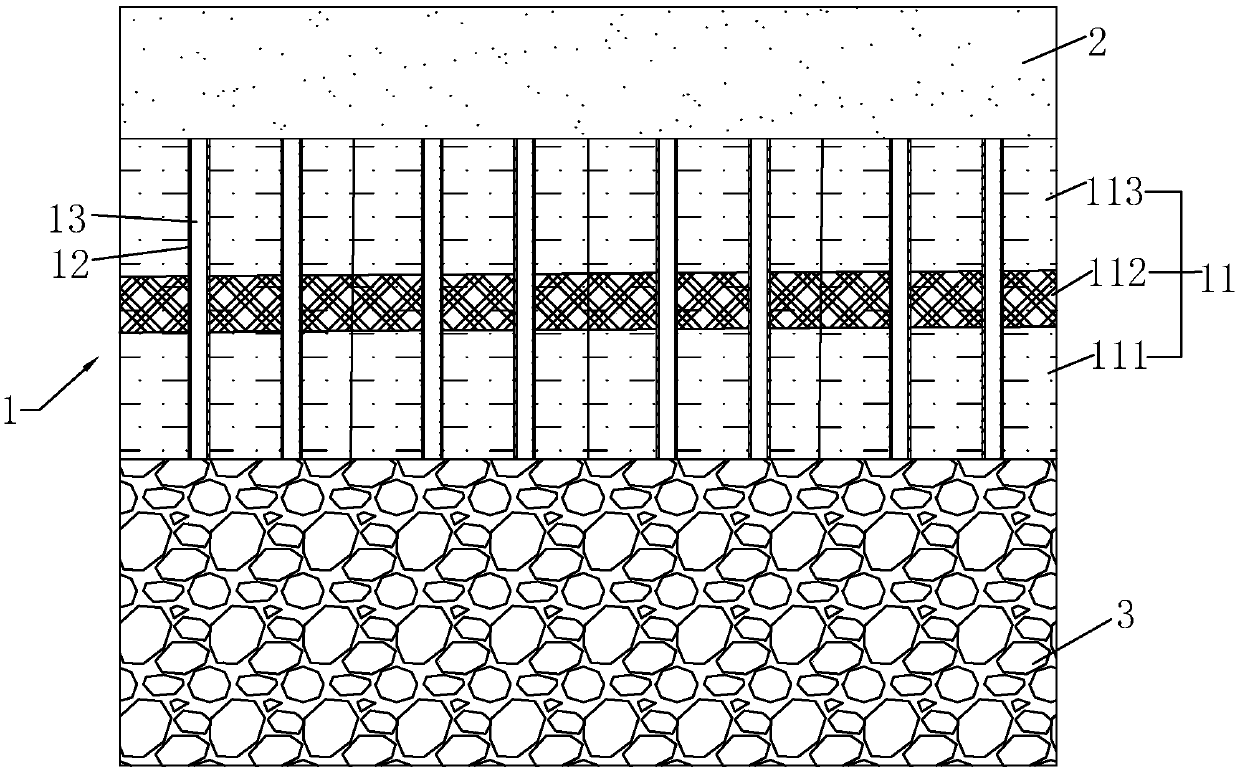

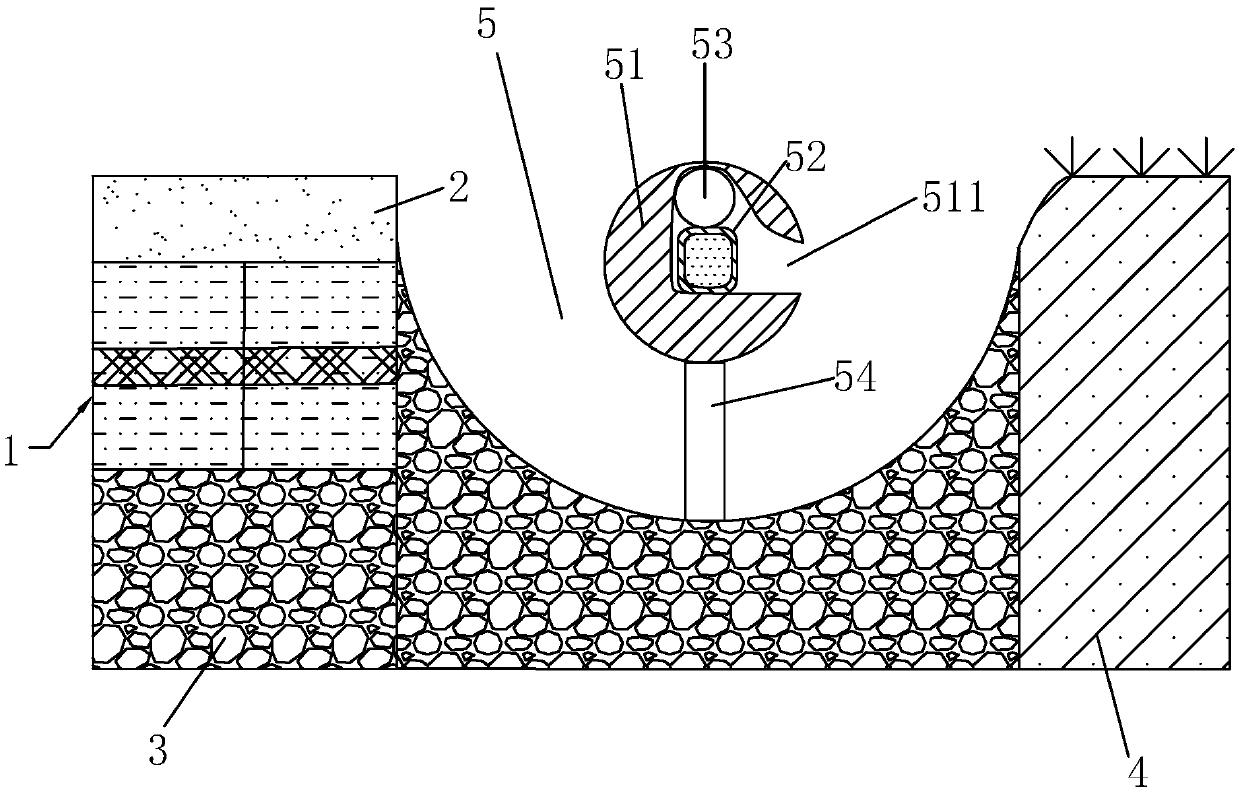

[0051] S2 Insert a hollow permeable pipe into the mold; weave the recycled steel bars to form a reinforcement layer for use;

[0052] S3 Pour half of the prefabricated slurry into the mold with the hollow permeable pipe inserted. After the prefabricated slurry is solidified, place the reinforcement layer woven in S1 on the solidified prefabricated slurry; then pour the remaining prefabricated slurry The material solidifies to form the top prefabricated layer.

[0053] Insert the permeable pipe in advance, on the one hand, it is not easy to block the cavity of the permeable pipe, on the other hand, the permeable pipe and the prefabricated slurry are better bonded. First import half of the prefabricated slurry, and place the reinforcement layer after solidification. It has better support for the reinforcement layer and easier to control the...

Embodiment 10

[0066] Preparation method of environment-friendly road paving block

[0067] In order to further improve the comprehensive index of the paving block and improve the construction efficiency, the inventor further improved the preparation method of the environmental protection road paving block. The difference between the preparation method of Example 10 and the above environmental protection road paving block is: The steel bar is inserted into the permeable pipe in the finished product obtained in S3, and the finished product is heated at a temperature of 850-880°C for firing for more than 72 hours.

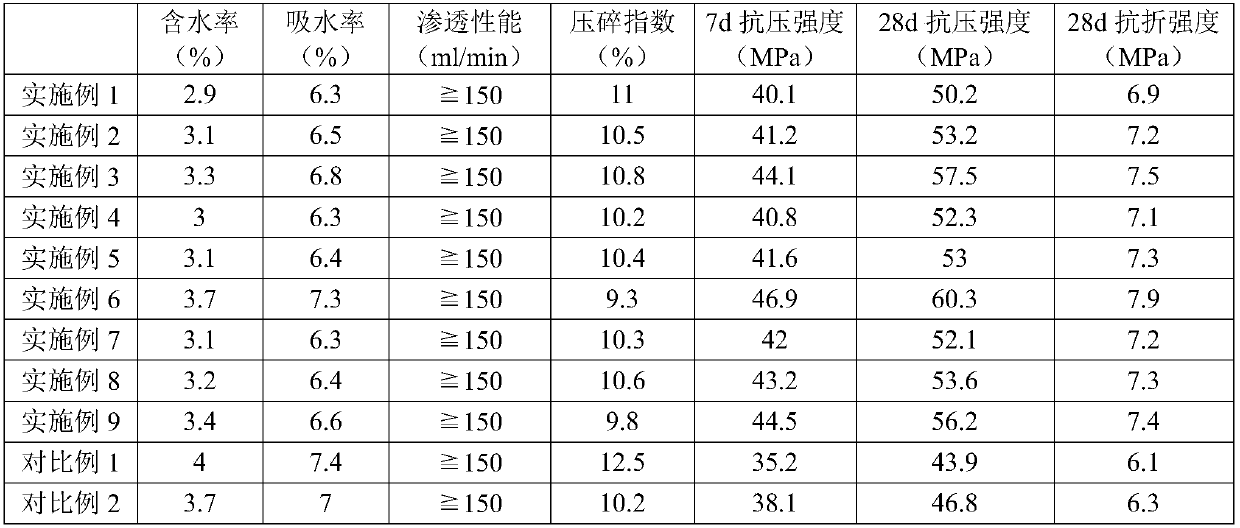

[0068] In order to save test costs, the inventors only made the above improvements to the paving blocks prepared in Examples 3, 6, and 9. Although the water permeability was slightly reduced, it still reached T2 classification (≧150ml / min), compressive strength and resistance The folding strength is greatly improved, both increased by 12%-15%.

Embodiment 11

[0070] Construction waste treatment method

[0071] The comprehensive index of the paving block, the efficiency of the entire construction also includes the early garbage treatment. The inventor also improved the construction waste treatment method. The specific steps are as follows:

[0072] Step 1. Screening, screening the construction waste to obtain initial aggregates, stones, steel bars, plastics and other waste;

[0073] Step 2. Crush the rocks, put the rocks in a cooling chamber below 0°C for cooling, cool for more than 10 minutes and then crush them, and then screen them to obtain cooled aggregates after crushing;

[0074] Step 3. The initial aggregate obtained by the screening and the cooled aggregate are mixed and used in the environmental protection road paving blocks of Examples 3, 6, and 9.

[0075] After the above treatment, the stones are more easily broken, which is beneficial to improve the construction efficiency.

[0076] Furthermore, in step 2, spray water to lower th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com