Rotating measurement device for outlet temperature field of aero-engine combustion chamber

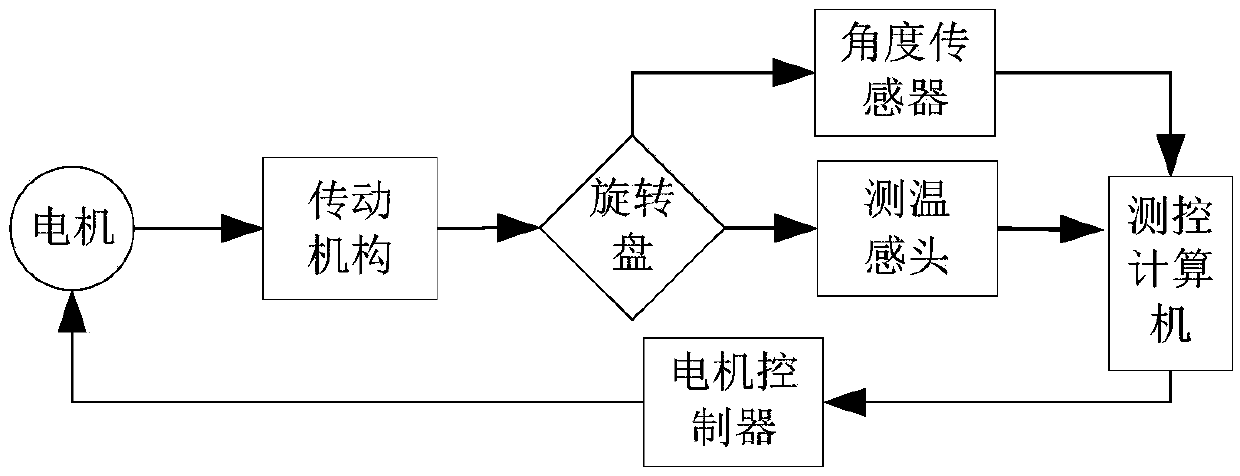

An outlet temperature field and aero-engine technology, which is applied to engine components, gas turbine devices, machines/engines, etc., can solve the problems of poor test state stability, limited space distribution of sensor head mounts, and long test cycle, etc., to shorten the test cycle , The effect of saving test funds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

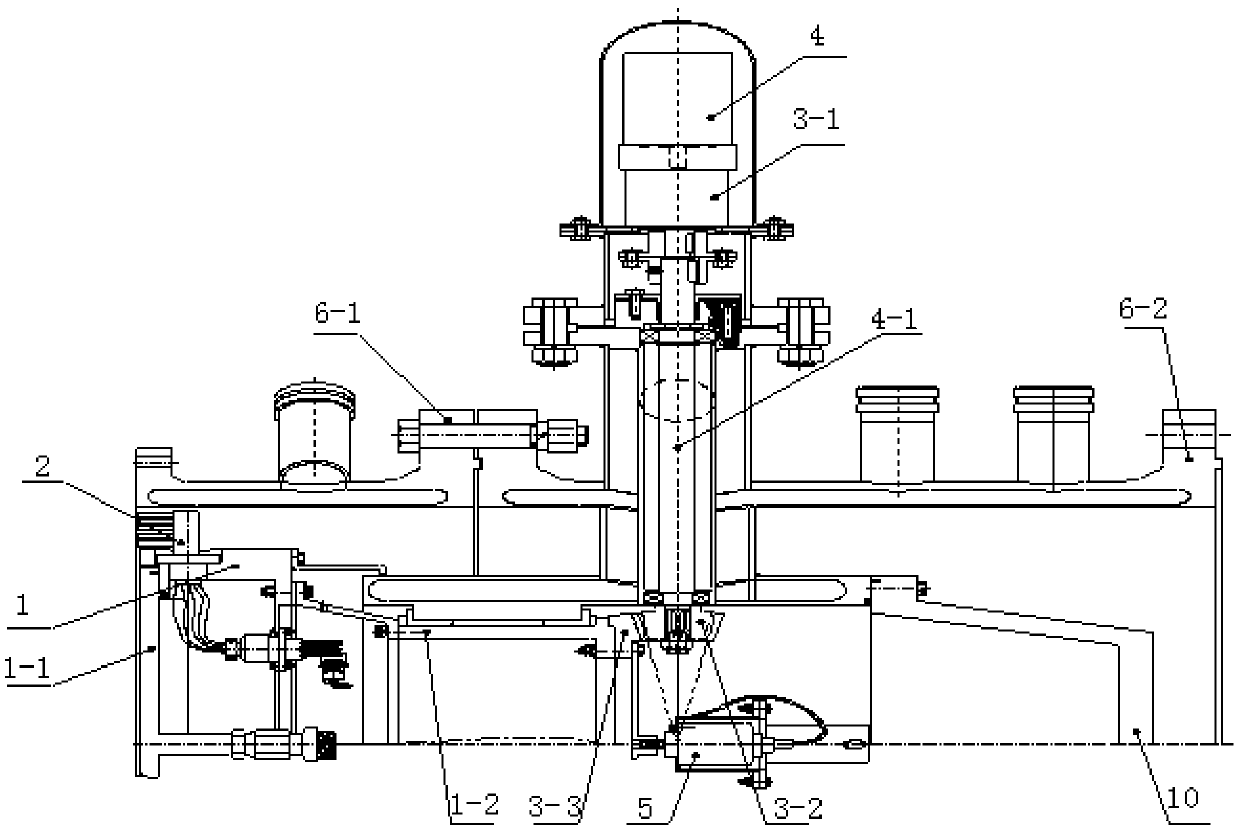

[0033] The specific implementation manner of the present invention will be described in detail in conjunction with the summary of the invention and the accompanying drawings.

[0034] Aiming at the high temperature and high pressure temperature field sampling environment, the corresponding design and verification were carried out, the design difficulties of each system were solved, a set of rotating temperature measurement device was manufactured, and the temperature field measurement was successfully achieved in the combustion chamber test work application.

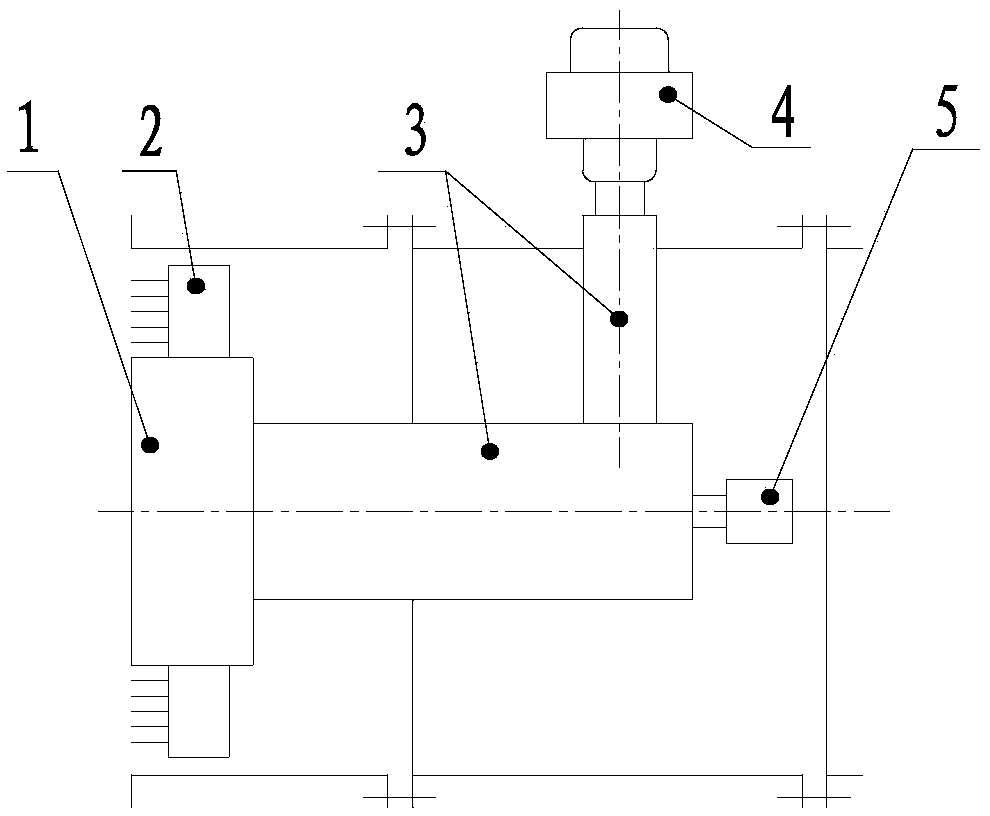

[0035] 1) Transmission mechanism: Through the force analysis and calculation of the transmission mechanism 3, the power device and transmission parts that meet the requirements are selected, and the requirements of large torque output and orthogonal torque transmission of the rotating parts are realized, and the work is stable and reliable.

[0036] The transmission mechanism 3 is developed by a DC servo motor 4 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com