Simulation oil quantity distributing and testing equipment of wind power gearbox

A wind power gearbox and distribution test technology, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problem that the oil distribution test technology is not particularly mature, the design of the lubricating oil circuit is unreasonable, and the waiting period Long-term problems, to achieve the effect of shortening the research and development cycle, small quality, and short time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

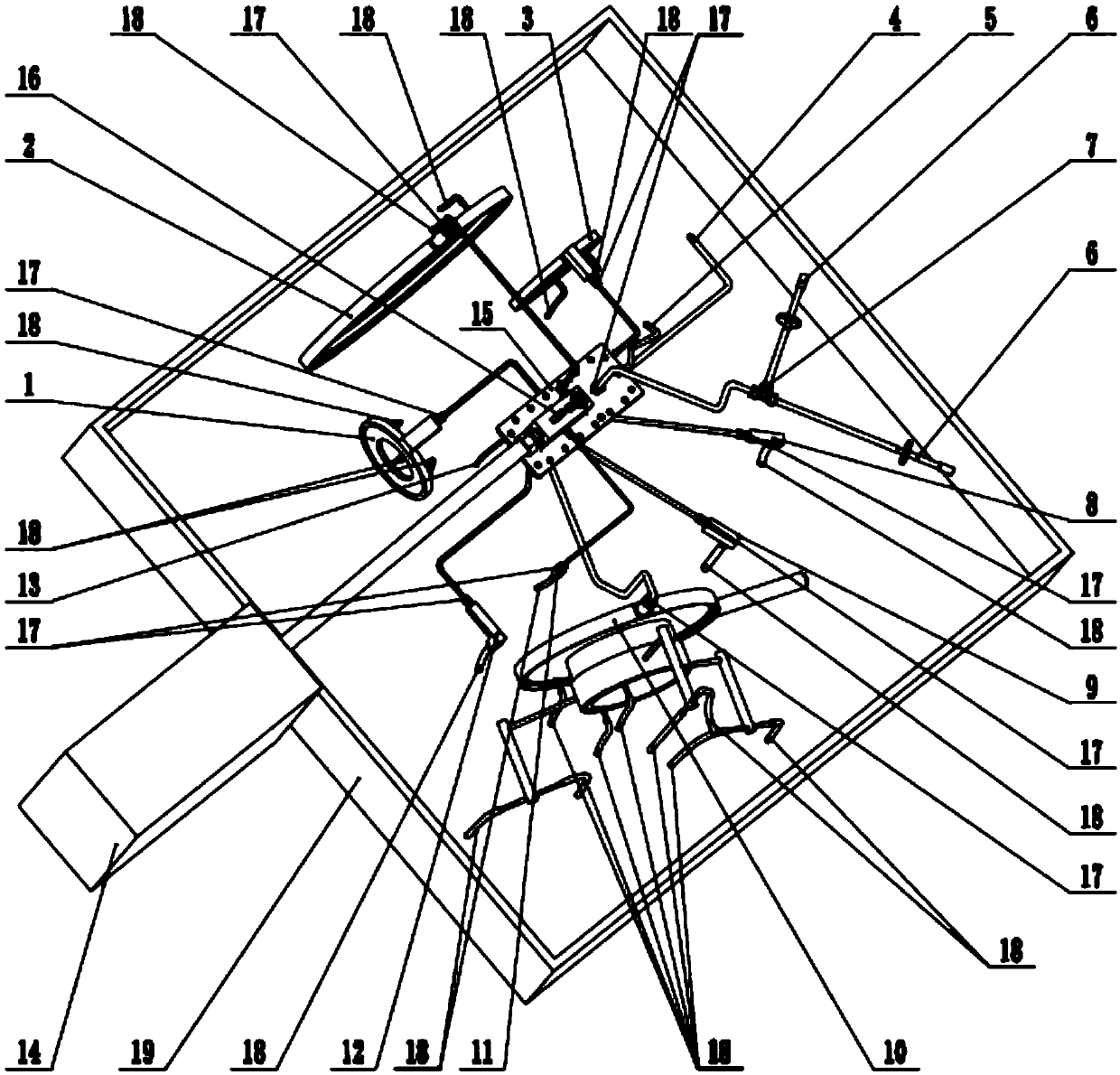

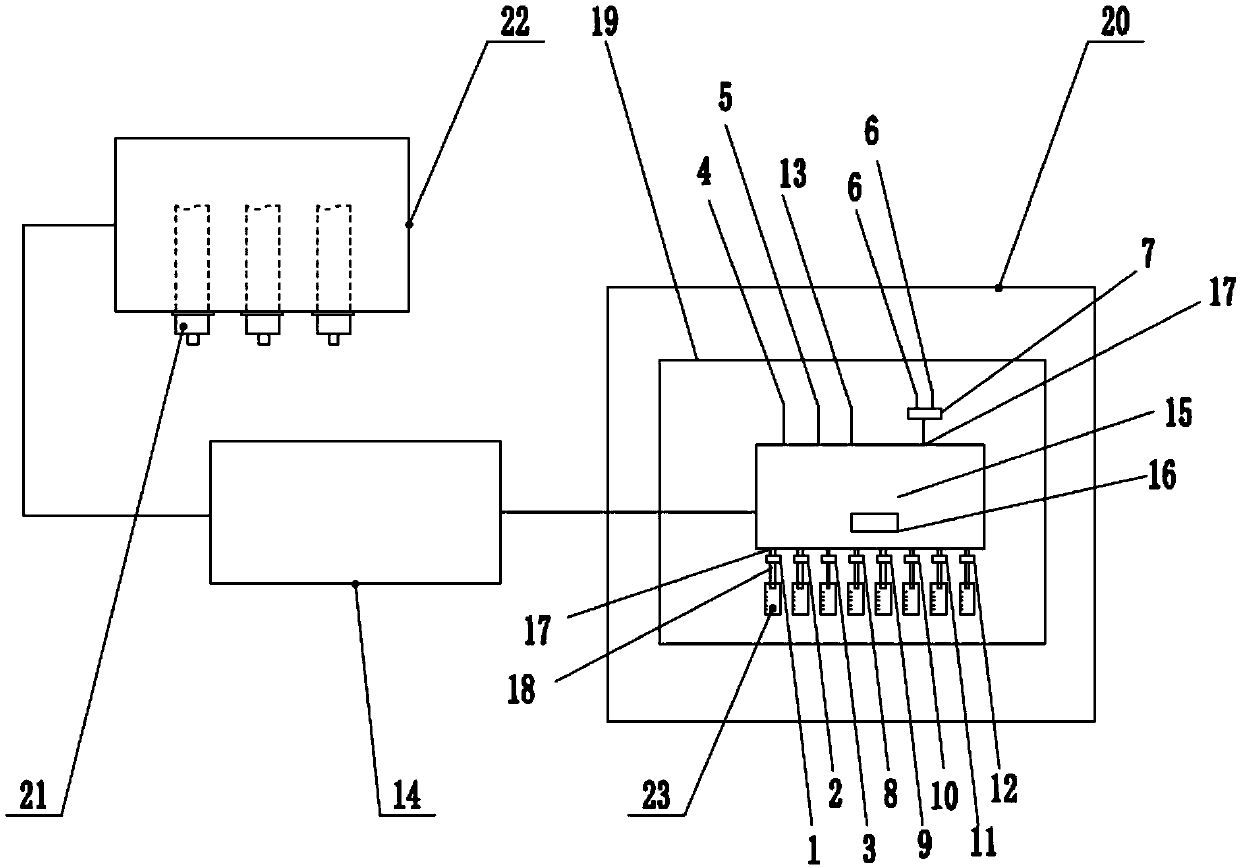

[0025] In order to illustrate the technical solution of the present invention more clearly, the accompanying drawings that need to be used in the description will be briefly introduced below. Obviously, the accompanying drawings in the following description are only some embodiments of the present invention. As far as people are concerned, other embodiments can also be obtained according to these drawings on the premise of not paying creative work.

[0026] Such as figure 1 , figure 2 Shown:

[0027] The simulated oil volume distribution test of the present invention is connected with pipe joints and steel pipes of corresponding specifications and models through the tooling of each simulated lubricating oil channel in the gearbox, and is connected to the oil distributor (oil distributor) respectively. The device is the existing equipment that distributes lubricating oil to each lubricating point), drives the lubricating oil in the simple oil station through the motor pump, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com