A method and device for calculating isokinetic parameters of a film layer etched area

A technology of mechanical parameters and film layer etching, applied in computer-aided design, calculation, electrical digital data processing, etc., can solve the problems that can only be used in regular areas and is difficult, and achieve easy implementation, low cost and time consumption , the effect of accurate calculation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

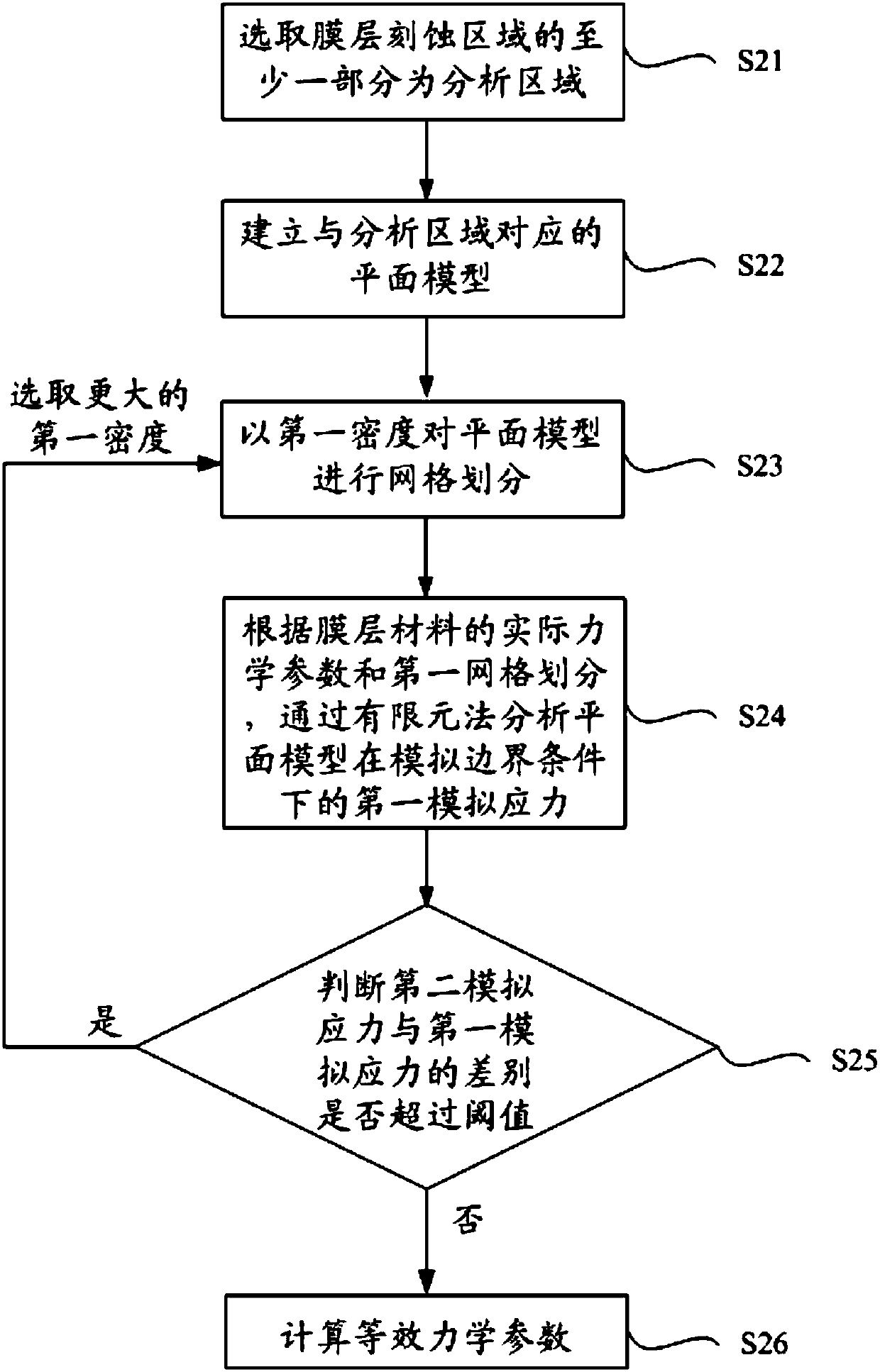

[0058] This embodiment provides a method for calculating the equivalent mechanical parameters of the film etching region, which includes:

[0059] S11. Selecting at least a part of the etching area of the film layer as the analysis area;

[0060] S12. Establishing a plane model corresponding to the analysis area;

[0061] S13. Carrying out grid division on the planar model with the first density;

[0062] S14, according to the actual mechanical parameters of the film layer material and the grid division of the first density, the first simulated stress of the plane model under simulated boundary conditions is analyzed by the finite element method;

[0063] S15. Calculate the equivalent mechanical parameters, wherein, under the simulated boundary conditions, the equivalent mechanical parameters can make the anisotropic blind plate with the same boundary size as the plane model reach the first simulated stress.

[0064] In the calculation method of the equivalent mechanical p...

Embodiment 2

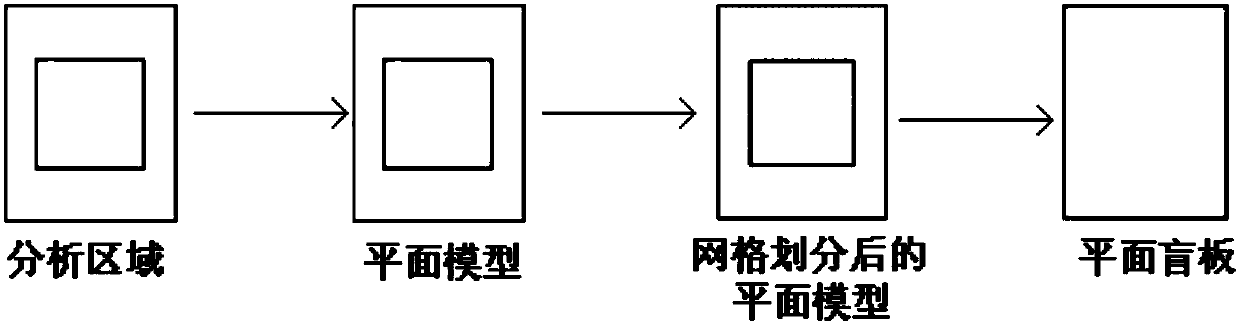

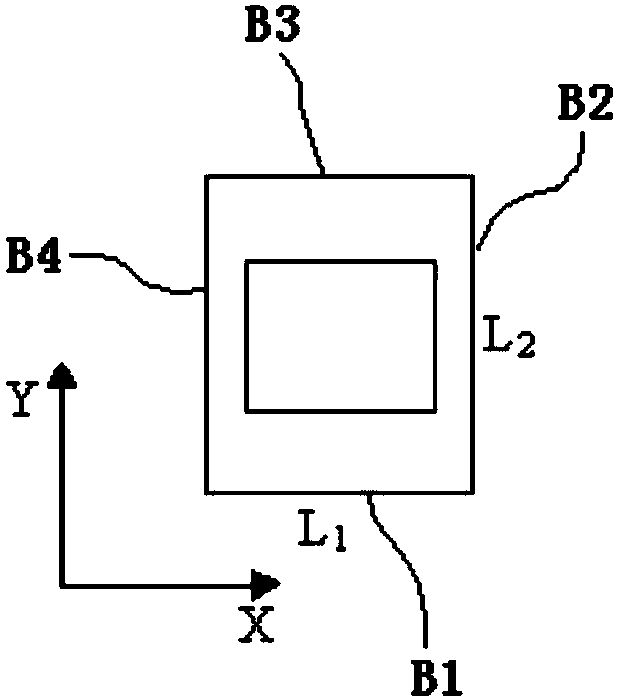

[0066] Such as Figure 1 to Figure 8 As shown, this embodiment provides a method for calculating the equivalent mechanical parameters of the etched area of the film layer.

[0067] Wherein, the etched area refers to an area with certain etched openings (patterns) in the film layer of the substrate (such as the display substrate).

[0068] The equivalent mechanical parameter refers to: if the etching area is regarded as an anisotropic planar blind plate (that is, a complete two-dimensional plate with different mechanical properties in each direction, no thickness, and no opening), the planar blind plate can be made Mechanical parameters that exhibit the same mechanical behavior as the actual etched area. Specifically, the equivalent mechanical parameters may include equivalent elastic modulus, equivalent Poisson's ratio, and the like.

[0069] The calculation method of the equivalent mechanical parameters of the film layer etching region in this embodiment specifically incl...

Embodiment 3

[0128] This embodiment provides a calculation device for the equivalent mechanical parameters of the film etching area, which includes:

[0129] an area selection unit, configured to select at least a part of the film etching area as the analysis area;

[0130] a model building unit for building a planar model corresponding to the analysis area;

[0131] A meshing unit, used for meshing the planar model;

[0132] The simulated stress calculation unit is used to analyze the simulated stress of the plane model under simulated boundary conditions through the finite element method according to the actual mechanical parameters of the film material and the current grid division;

[0133] The equivalent mechanical parameter calculation unit is used to calculate the equivalent mechanical parameter, wherein, under the simulated boundary conditions, the equivalent mechanical parameter can make the anisotropic blind plate with the same boundary size as the plane model reach the first si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com