Voltage-withstanding flexible liquid cooling fin

A liquid-cooled heat dissipation and heat sink technology, applied in the field of liquid-cooled heat sinks, can solve the problems of channel area reduction, poor heat dissipation, blocking, etc., and achieve the effects of flexible layout, high reliability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with drawings and embodiments. The embodiments described with reference to the drawings are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

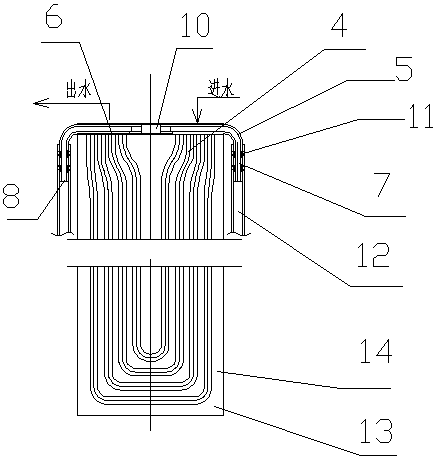

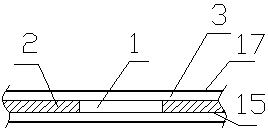

[0027] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the liquid cooling fin of this embodiment is formed by bonding two outer aluminum sheets 3 and one middle rubber sheet 2 . A semicircle shape is punched out on the upper end of the outer aluminum sheet 1, the two semicircles are oppositely arranged and an aluminum tube 5 is placed in the area formed by the two semicircles oppositely arranged, the lower end of the outer aluminum sheet 3 is a flat sheet structure, and the middle rubber sheet 2 A plurality of flow channel gaps 1 are punched out by stamping, and the flat sheet structure at the lower end of the outer aluminum sheet 3 forms a liquid flow channel 4 with the flow c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com