Ultra-thick steel material having excellent resistance to brittle crack propagation and preparing method therefor

A technology of crack propagation and manufacturing method, applied in the field of ultra-thick steel and its manufacturing, can solve the problems of difficult application of manufacturing cost, and achieve the effect of excellent resistance to brittle crack growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0106] The present invention will be described more specifically by way of examples below. It should be noted that the following examples are only used to illustrate the present invention, and are not intended to limit the scope of rights of the present invention. Because, the scope of rights of the present invention depends on the contents described in the claims and the contents reasonably derived therefrom.

[0107] The present invention is described below by way of examples.

[0108] (Example)

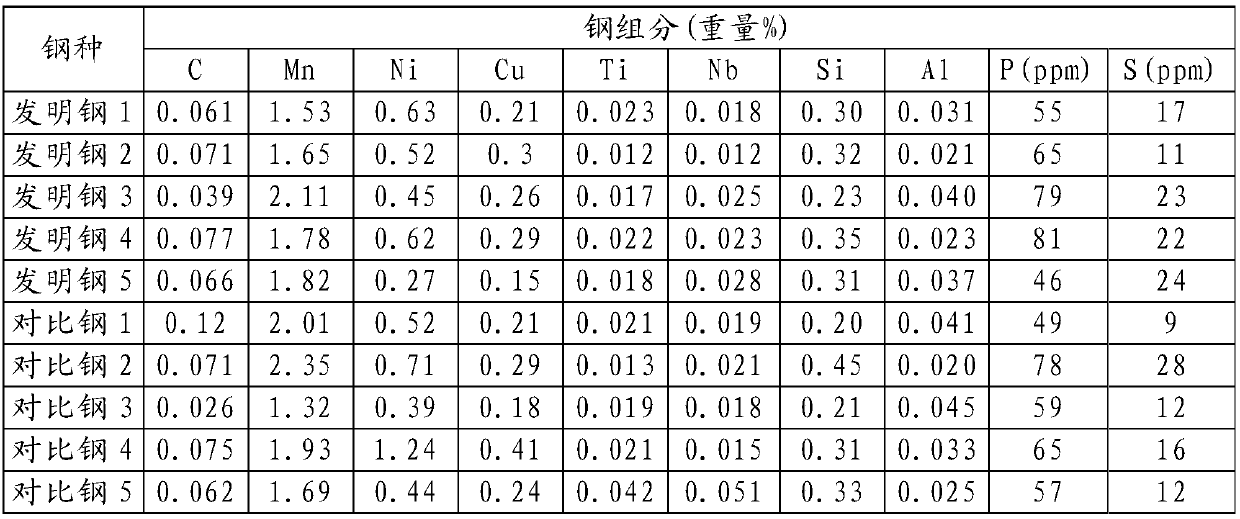

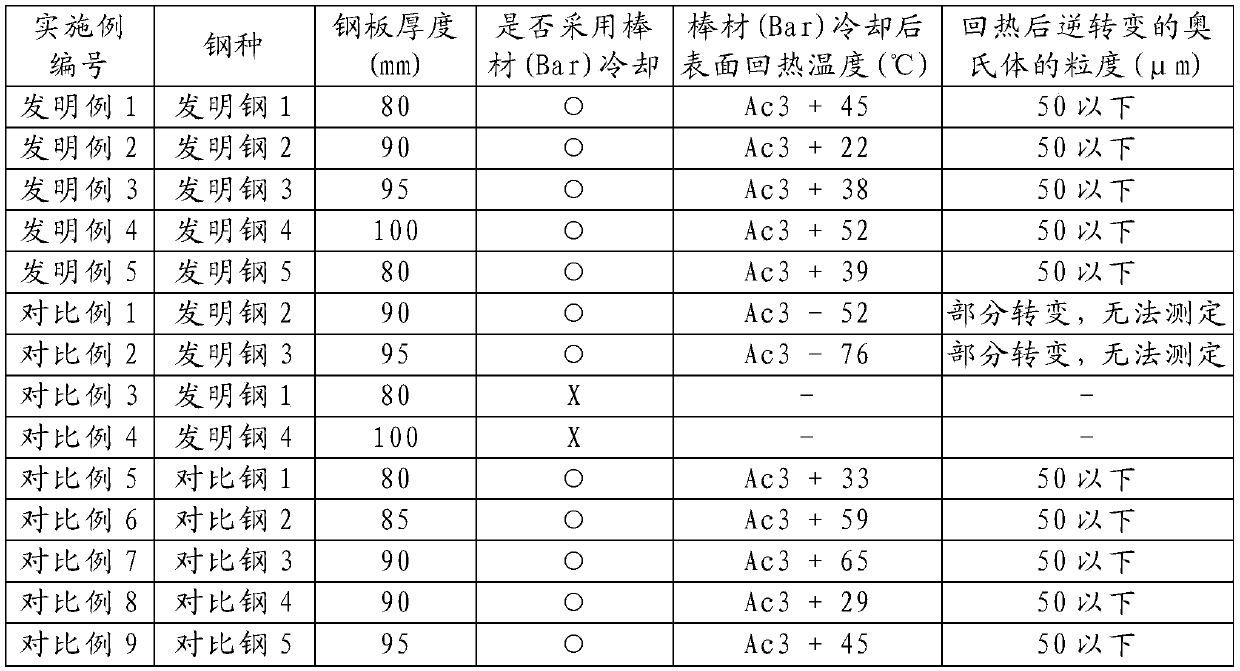

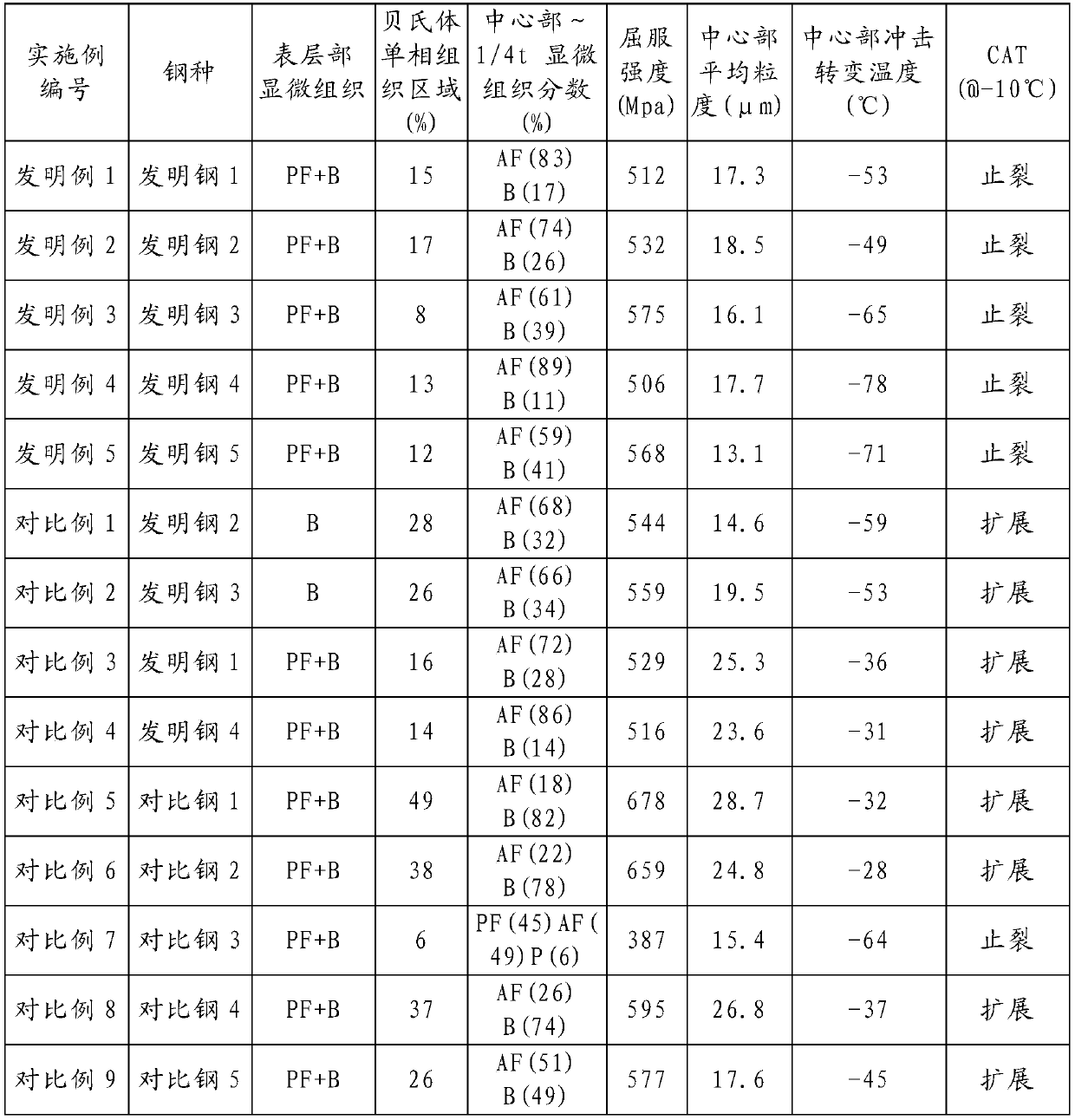

[0109] A steel slab having a thickness of 400 mm having the composition of Table 1 below was reheated at a temperature of 1070° C., and rough rolling was performed at a temperature of 1025° C. to produce a bar. The same cumulative reduction ratio was used during rough rolling, and the cumulative reduction ratio was 50%.

[0110] The thickness of the bar after the rough rolling is 200mm. After the rough rolling, the bar is cooled and then reheated. The surface reheating temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap