Shared multifunctional washer used for supermarket, washing method and water control system

A multi-functional, cleaning machine technology, applied in the field of cleaning machines, can solve the problems of complex procedures, few storage types, and large equipment limitations in vegetable cleaning factories, so as to reduce the number of cleaning times at home, reduce weighing personnel, and save water. resource effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

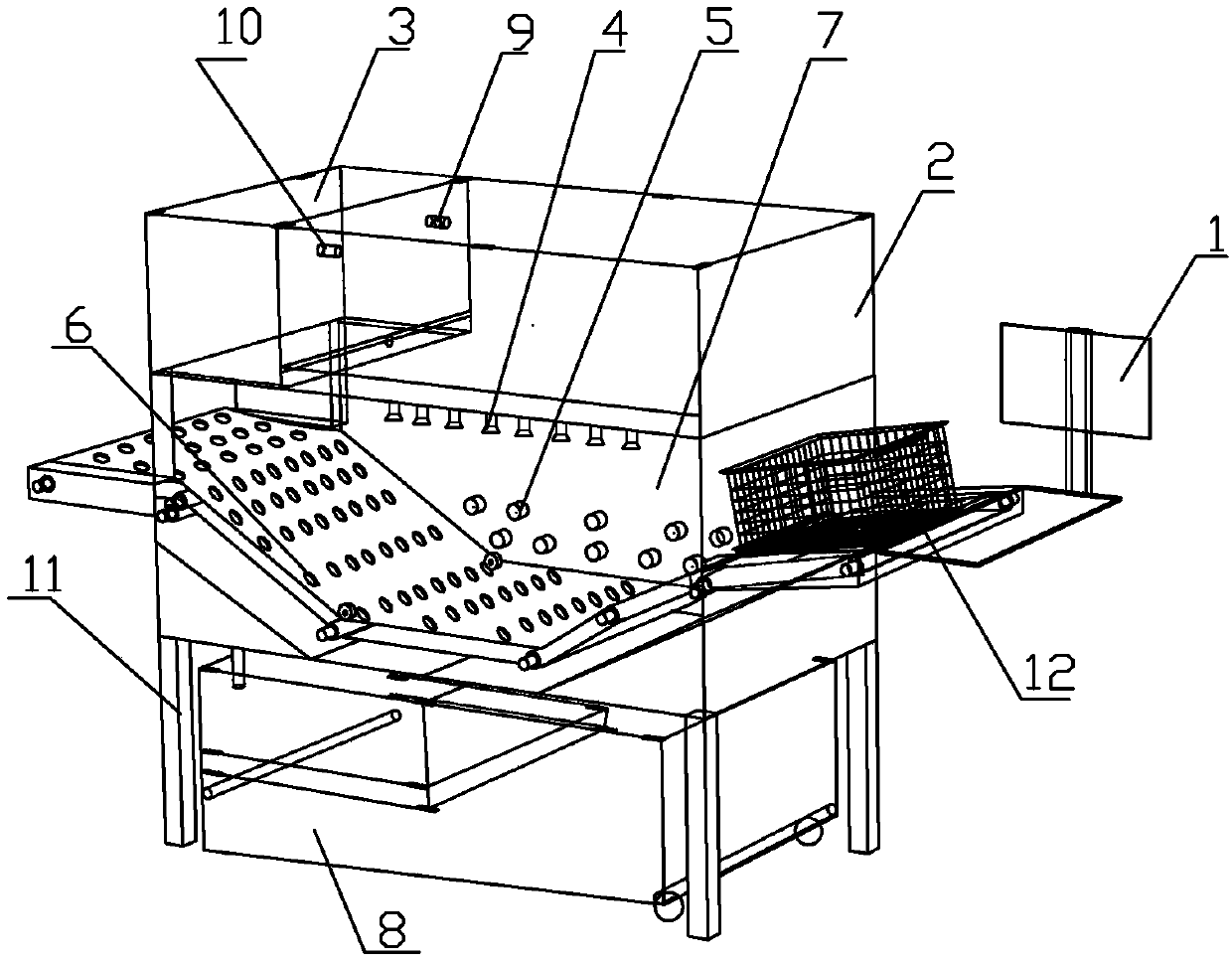

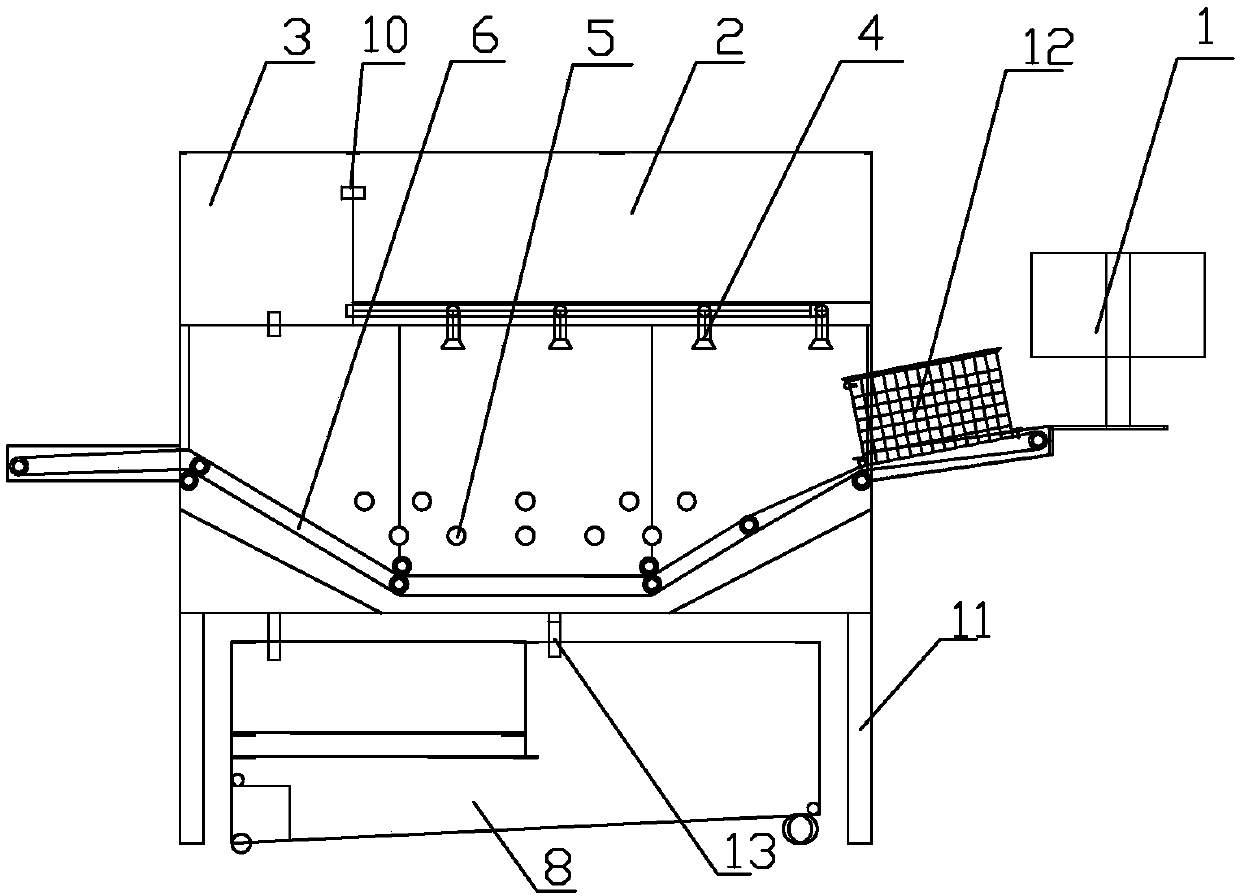

Embodiment 1

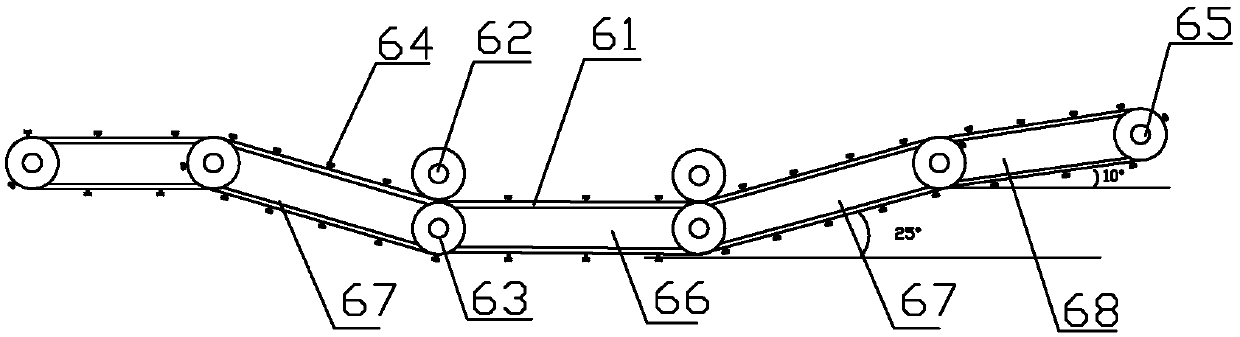

[0052] (1) Put the purchased fruits into the drain basket and weigh them with an automatic electronic scale. Select the button of the corresponding fruit on the screen of the automatic electronic scale, and the unit price, total price and weight information of the corresponding fruit will be displayed on the screen. After checking, click the confirmation button to complete the purchase.

[0053] (2). Then the weighed drain basket is clamped on the conveyor belt, the sensor probe at the entrance of the chassis receives the signal after 3 seconds, the motor is started, and the conveyor belt starts to rotate.

[0054] (3) When the drain basket moves 20mm forward under the rotation of the conveyor belt, the next sensor probe receives the signal to open the solenoid valve, and the ozone water passes through multiple nozzles to clean the fruit with ozone water.

[0055] (4) The drain basket continues to advance 30mm, the next sensor probe receives the signal and then turns on the ultrasoni...

Embodiment 2

[0058] (1) Put the purchased vegetables into the drain basket and weigh them with an automatic electronic scale. Select the button of the corresponding vegetable on the screen of the automatic electronic scale, and the unit price, total price and weight information of the corresponding fruit will be displayed on the screen. After checking, click the confirmation button to complete the purchase.

[0059] (2). Then the weighed drain basket is clamped on the conveyor belt, the sensor probe at the entrance of the chassis receives the signal after 3 seconds, the motor is started, and the conveyor belt starts to rotate.

[0060] (3) When the drain basket moves 20mm forward under the rotation of the conveyor belt, the next sensor probe receives the signal to open the solenoid valve, and the ozone water passes through multiple nozzles to clean the vegetables.

[0061] (4) The drain basket continues to move forward 30mm, the next sensor probe receives the signal and turns on the ultrasonic in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com