Flexural structure of straddle type monorail transit joint type flexible turnout

A straddle-type monorail and transportation technology, applied in the field of flexural structures, can solve the problems of inconvenient equipment installation and daily maintenance, and less free space for the beam body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings.

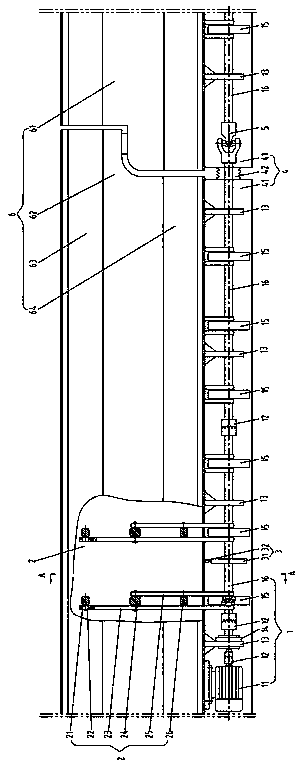

[0027] like figure 1 As shown, the present invention discloses a flexure structure of a straddle-type monorail traffic joint flexible turnout, which includes a beam body, the beam body includes a beam body, and two parallel and facing guide panels are respectively installed on both sides of the beam body. A stable panel on the same vertical plane as the guide panel is also installed directly below each guide panel;

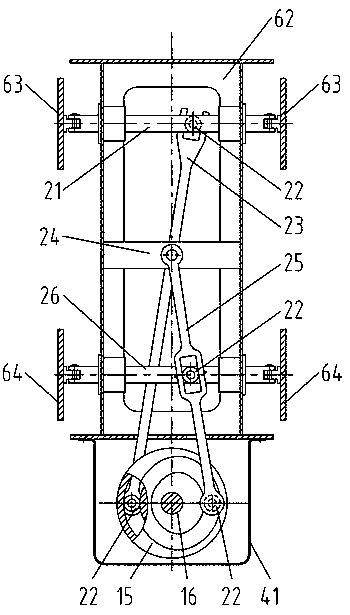

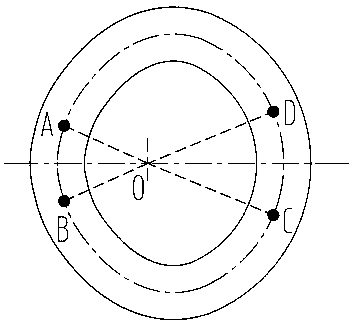

[0028] It also includes a plurality of flexure elements installed at intervals along the length of the beam (such as figure 2 as shown, figure 2The flexure unit in can achieve leftward deflection, those skilled in the art should know that by changing the installation direction of each component, it can also realize rightward deflection), the flexure unit includes the drive assembly installed under the beam body , also includes an executive a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com