A kind of automatic packing method of medicine bottle

A fully automatic packaging and medicine bottle technology, applied in packaging, packaging machines, transportation and packaging, etc., can solve the problems of not achieving the expected effect, fragile medicine extrusion, no protection, etc., to achieve good protection and fast packaging speed , the effect of high intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

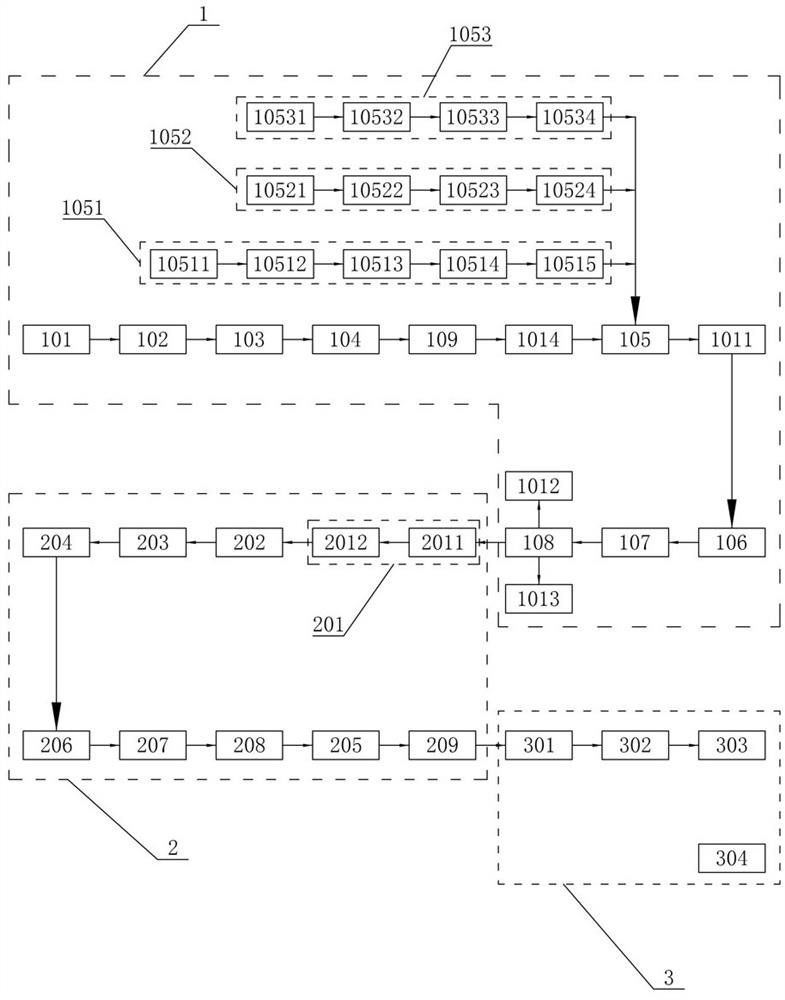

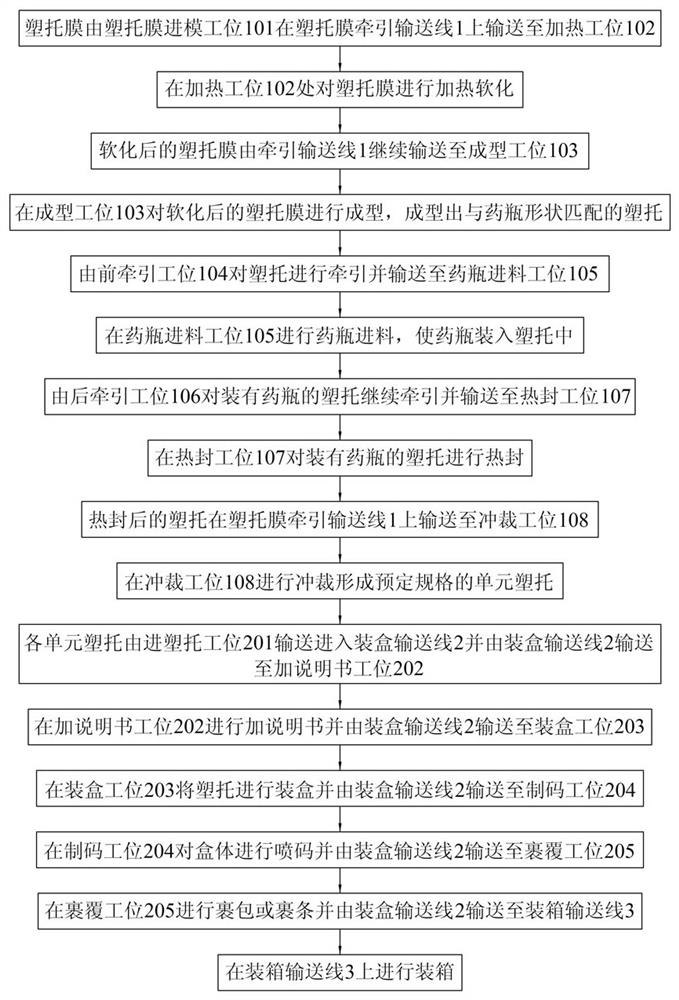

[0039] like figure 1 and figure 2 As shown, the fully automatic packaging method for medicine bottles in this embodiment includes a plastic tray film traction conveyor line 1, a box packing conveyor line 2 and a case packing conveyor line 3 connected in sequence, and the plastic tray film traction conveyor line 1 is provided with a plastic tray Film feeding station 101, heating station 102, forming station 103, front pulling station 104, medicine bottle feeding station 105, rear pulling station 106, heat sealing station 107 and punching station 108, The box conveyor line 2 is provided with a plastic feeding station 201, an instruction manual station 202, a cartoning station 203, a code making station 204 and a covering station 205, specifically including the following steps:

[0040] S1: The plastic support film is transported to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com