Integrated bulk machine

A bulk machine, integrated technology, applied in the direction of conveyor, loading/unloading, transportation and packaging, etc., can solve the problems of complex structural design, difficult operation, and difficult transfer of bulk machines, and achieve reasonable design, easy operation, and wide adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

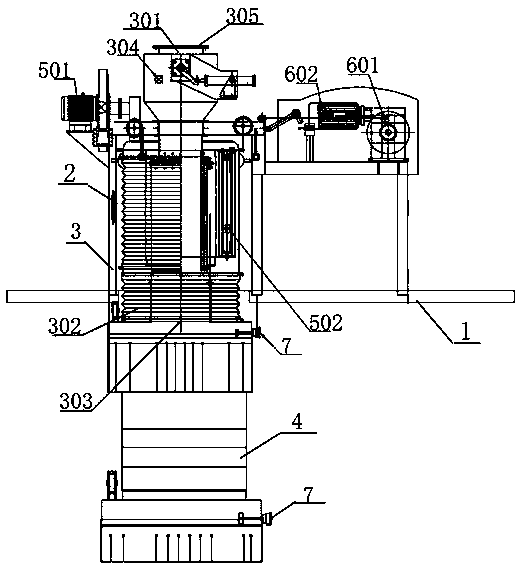

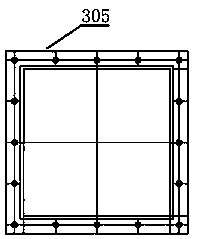

[0019] The integrated bulk machine includes a body support 1, a PLC controller 2, a silo 3, a dust collection system, a lifting system and a telescopic cylinder 4. The silo 3 is worn on the body support 1 and is fixedly connected by fasteners The PLC controller 2 is arranged on the silo 3; the dust collection system includes a dust collection fan 501, a dust collection pipe and a dust collection filter cartridge 502; one end of the dust collection pipe is connected to the dust collection fan 501, and the other end is connected to the dust collection fan 501. The dust collecting filter cartridge 502 is connected; the dust collecting fan 501 is fixed on the body support 1, and the dust collecting filter cartridge 502 is set in the silo 3; the silo 3 includes a feeding port 301 and a collecting bin 302, the discharge port 303 and the arc valve 304, the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com