Automatic feeding device of spun yarn tubes and control method of automatic feeding device

A technology of automatic feeding and control methods, applied in the textile field, can solve the problems of low labor intensity, low feeding efficiency, and high labor intensity of feeding, and achieve the goals of reducing labor intensity, improving efficiency, and improving accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

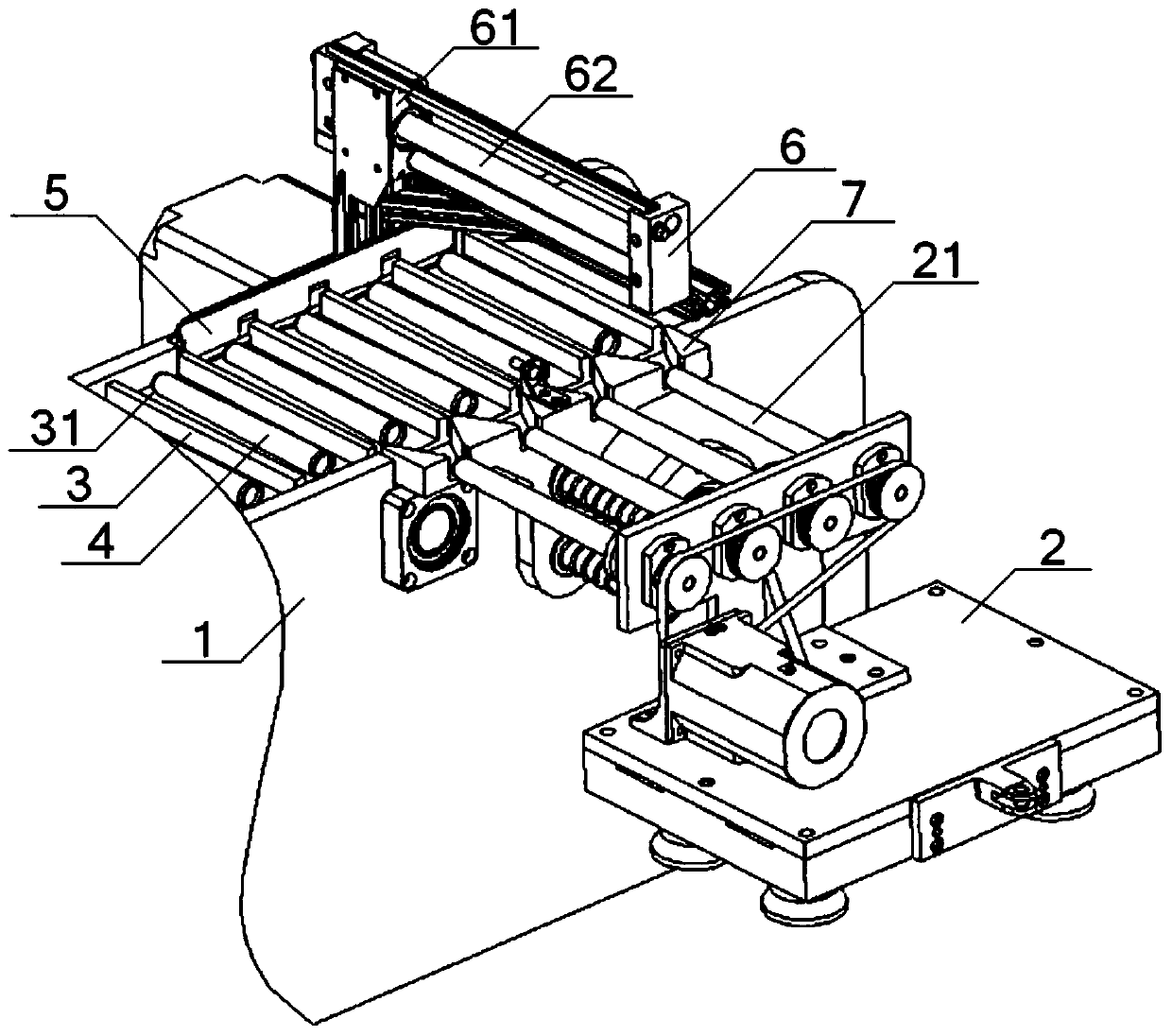

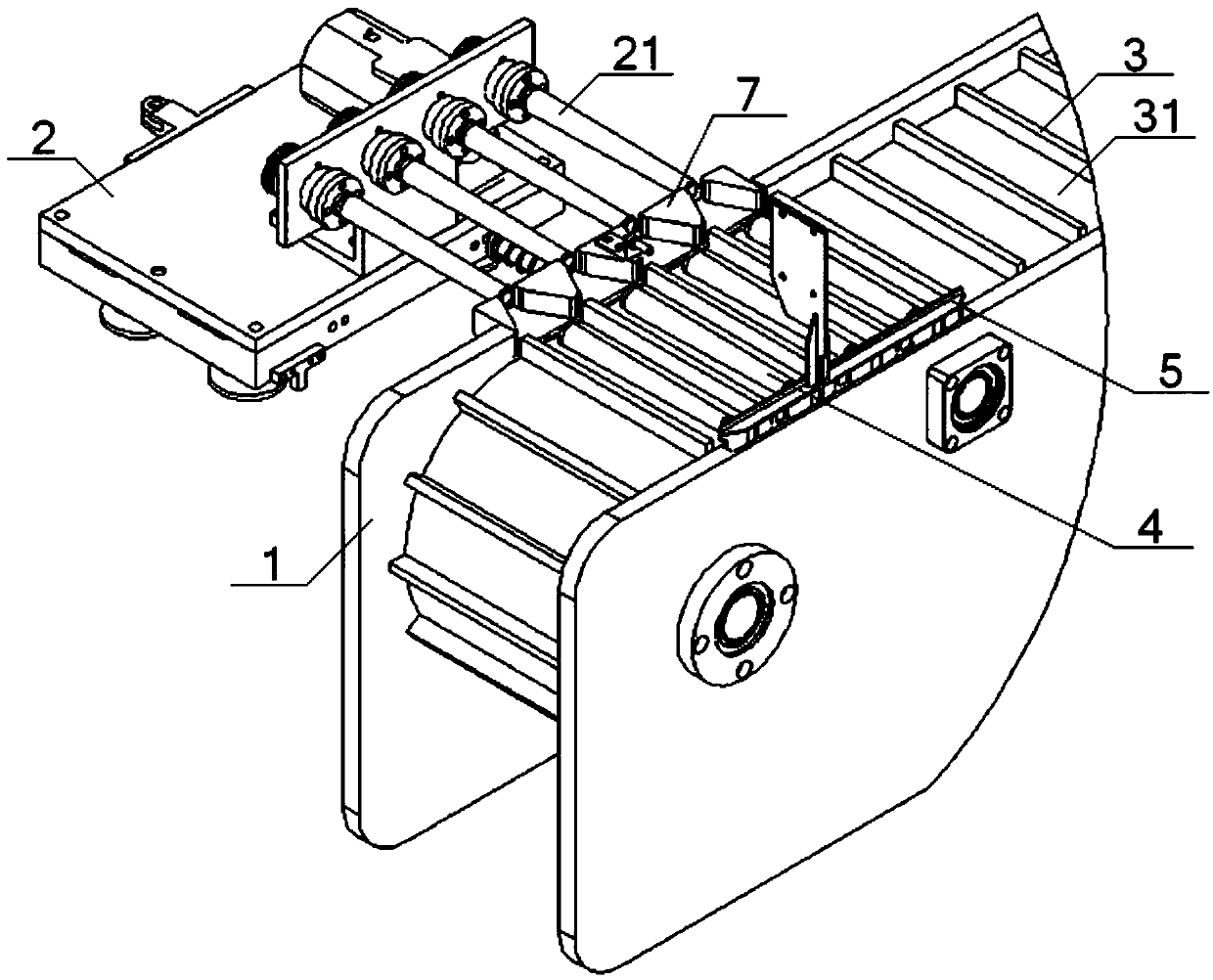

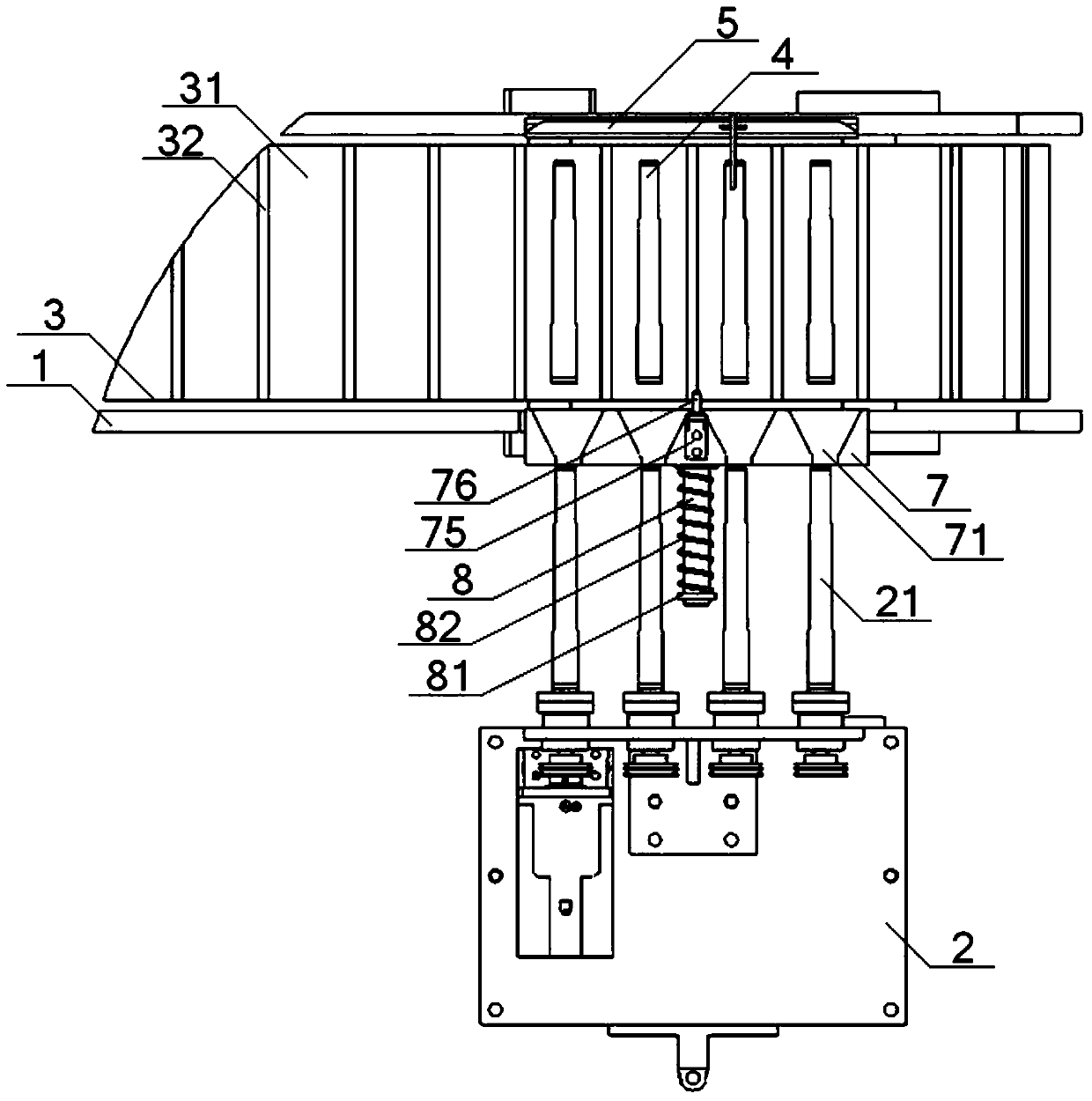

[0060] see Figure 1 to Figure 5 , an automatic feeding device for spinning bobbins, comprising a frame 1 and a conveying trolley 2, the frame 1 is provided with a conveyor belt 3, and the conveyor belt 3 is provided with a plurality of storage compartments 31, and the storage compartment 31 is provided with There is a spun bobbin 4, and the frame 1 is provided with a push plate 5 on one side of the storage compartment 31, the push plate 5 is connected with the slider 61 of the rodless cylinder 6, and the rodless cylinder 6 is arranged on the storage compartment 31. Above, the guide rail 62 of the rodless cylinder 6 is set along the length direction of the spinning bobbin 4, and the other side of the storage compartment 31 on the frame 1 is provided with a guide block 7, and the guide block 7 is sleeved on the guide rod 8 On, one end of the guide rod 8 is fixed on the frame 1, the other end of the guide rod 8 is covered with a baffle 81, and the position between the guide bloc...

Embodiment 2

[0063] Basic content is the same as embodiment 1, the difference is:

[0064] see Figure 1 to Figure 5 , the guide block 7 is a T-shaped structure, the guide block 7 includes a No. 1 block 72 and a No. 2 block 73, and the guide groove 71 is evenly arranged on the No. 1 block 72 along the running direction of the conveyor belt 3, guiding The groove 71 has a trapezoidal structure, the large opening end of the guiding groove 71 is aligned with the storage compartment 31, the small opening end of the guiding groove 71 is aligned with the casing 21, and a guide rod mounting hole 74 is provided on the second block 73; A bracket 75 is provided on the No. 1 block 72 between the guide grooves 71 , and a top cone 76 is vertically connected to the bracket 75 .

Embodiment 3

[0066] Basic content is the same as embodiment 1, the difference is:

[0067] see figure 1 , image 3 , Figure 4 , the storage compartment 31 includes two partitions 32 parallel to each other, the push plate 5 includes a toothed plate 51 and a connecting plate 52, the toothed plate 51 is connected with the slider 61 through the connecting plate 52, the toothed plate 51 The teeth 53 of the tooth plate 51 are located between the two partitions 32 and are perpendicular to the partitions 32 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com