Oily sludge circulation washing device

A technology for circulating washing and oily sludge, which is applied in sludge treatment, water/sludge/sewage treatment, water pollutants, etc., and can solve the problems of poor treatment effect and low treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] For better understanding and implementation, the specific implementation manners of the present invention will be further described in detail below in combination with examples and tables. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

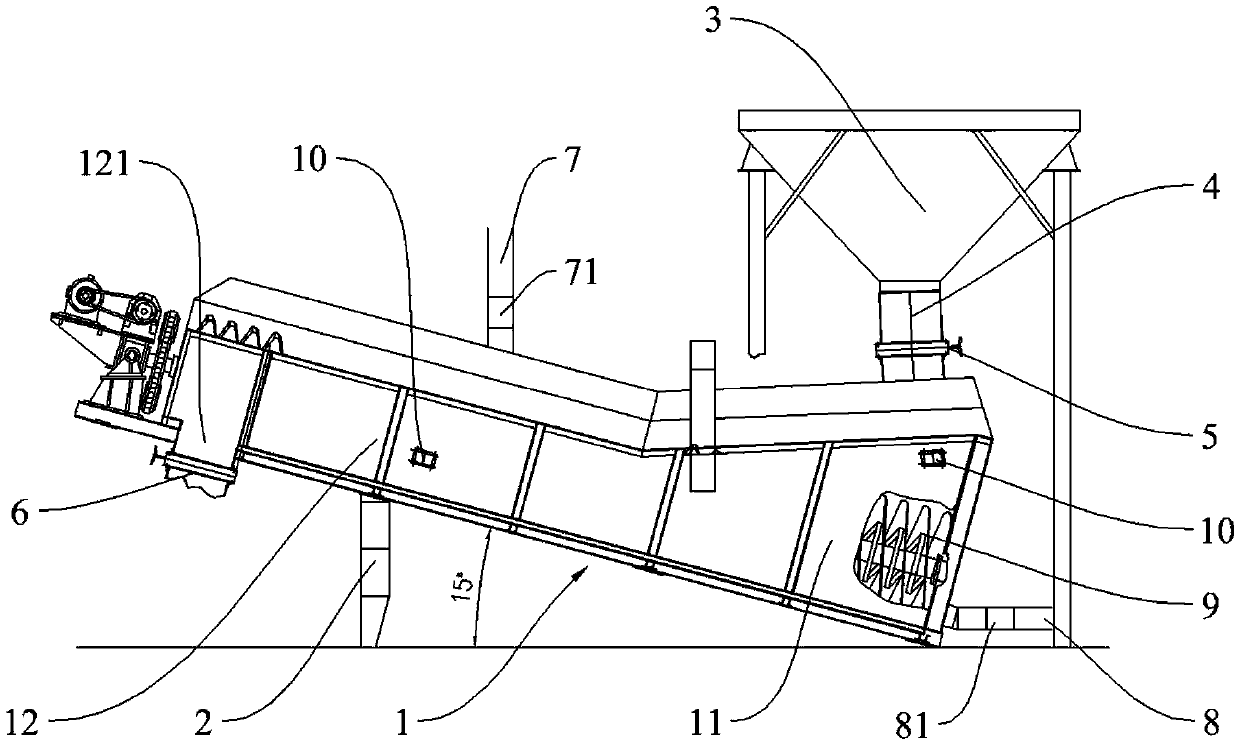

[0034] 1. The structure of the oil sludge circulation washing device

[0035] As shown in the figure, an oil sludge circulation washing device, its main structure includes a chassis 1 and legs 2, one end of the chassis 1 is set on the ground, and the other end is supported by the legs 2, so that the chassis 1 is inclined Setting, specifically, the cabinet 1 is divided into a feed part 11 and a discharge part 12. In this embodiment, the discharge part 12 is a cubic box tube with a certain length, and the feed part 11 is in a cubic shape. On the basis of the tank tube, the working space is expanded on the upper end surface to provide a larger loading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com