Apparatus and method for processing vacuum glass

A vacuum glass and glass plate technology, applied in the processing field, can solve problems such as low production efficiency, and achieve the effects of improving production efficiency, stable placement, and simplifying the processing technology

Pending Publication Date: 2019-04-05

YANGZHOU UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005]

The purpose of the present invention is to overcome the deficiencies in the prior art, provide a device for processing vacuum glass and its processing method, which solves the technical problem of low production efficiency in the prior art, and the present invention simplifies the processing technology and improves the production efficiency. efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0069] The difference between this embodiment and Embodiment 1 is that in step (2) of this embodiment, the accumulation height of the edge sealing solder is 0.5 mm.

Embodiment 3

[0071] The difference between this example and Example 1 and Example 2 is that in step (13), the unsintered vacuum glass is stacked and placed, and the stacked n pieces of unsintered vacuum glass are sent together into a vacuum sintering furnace for sintering (n≥2).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

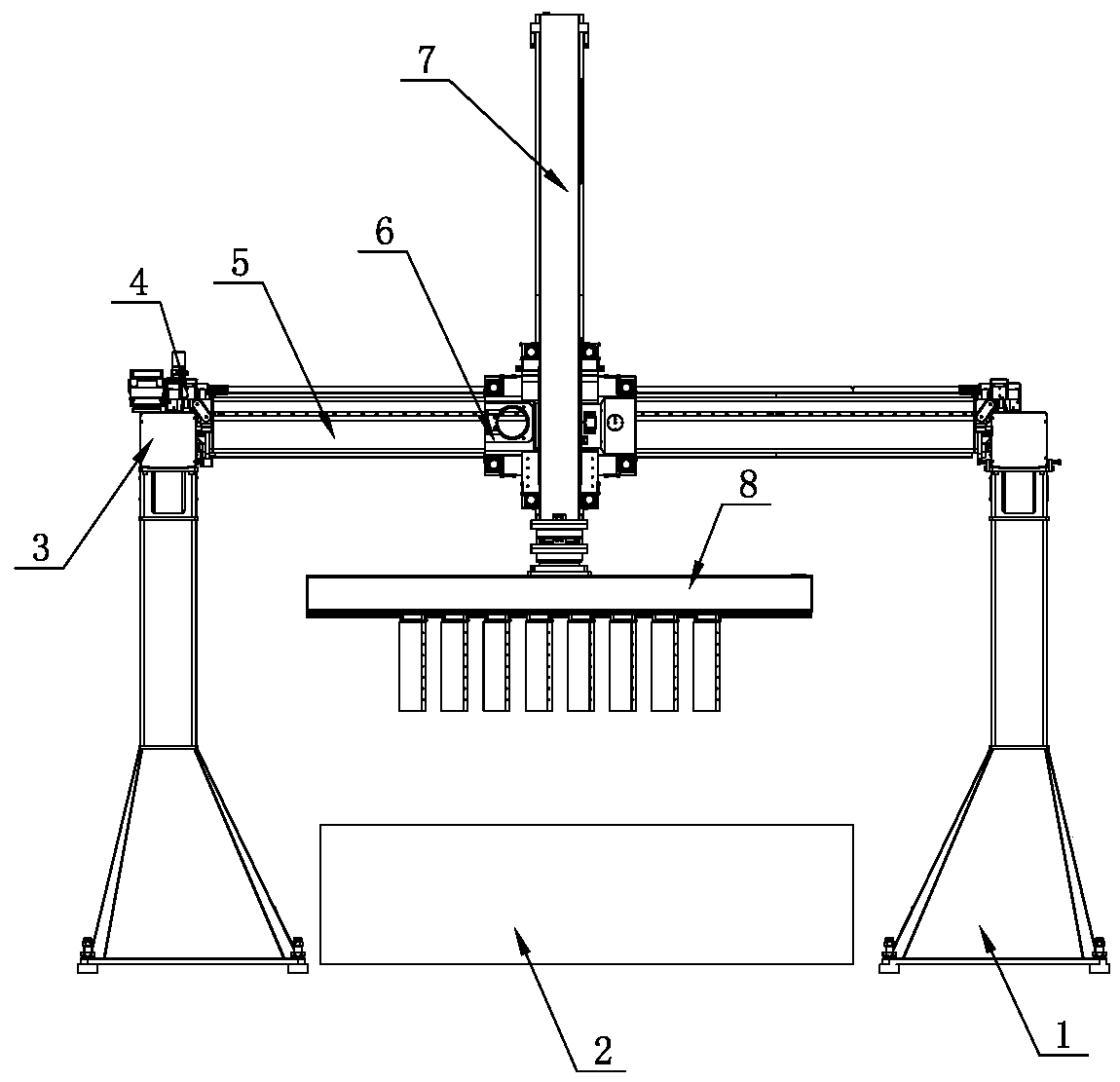

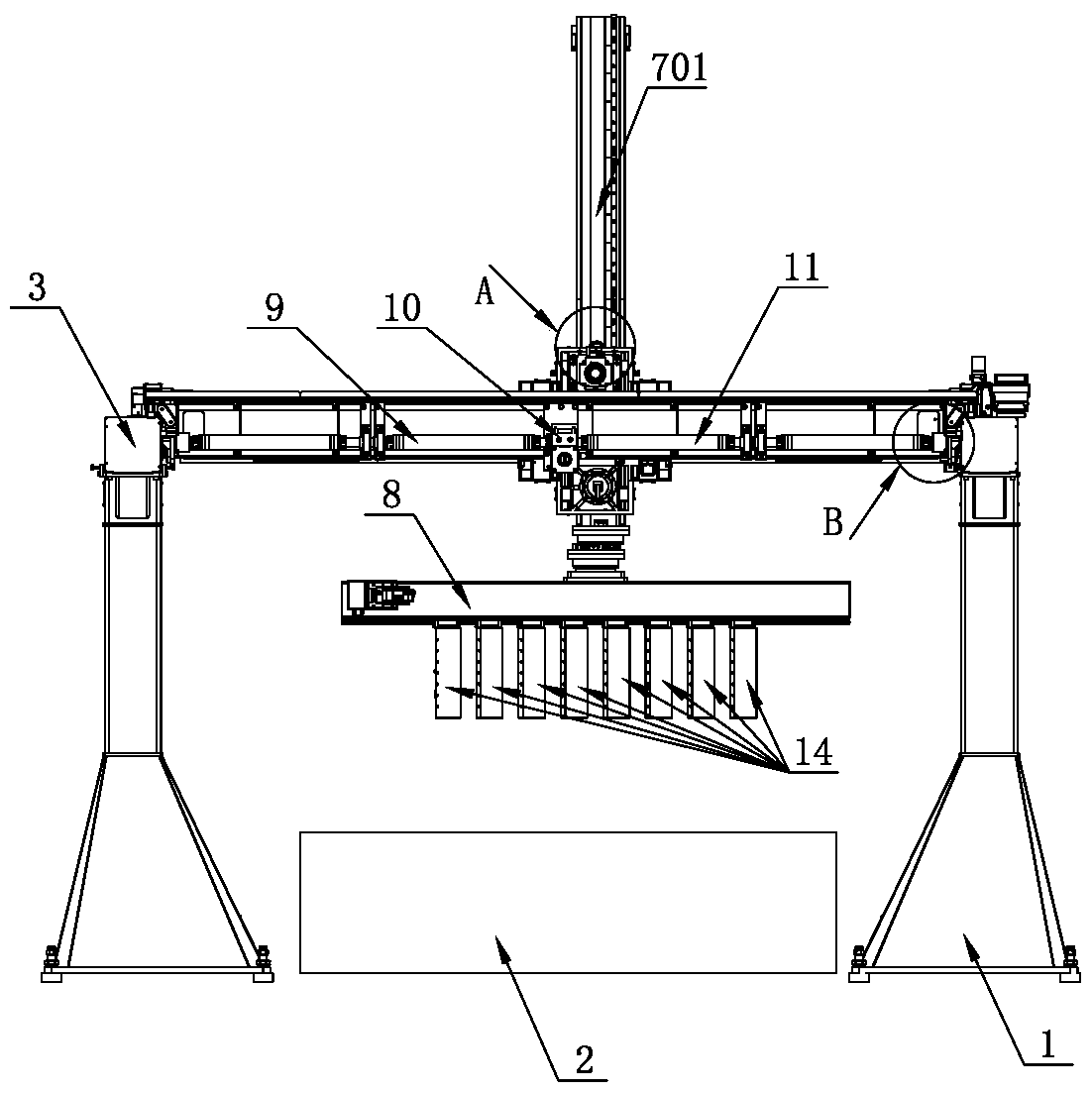

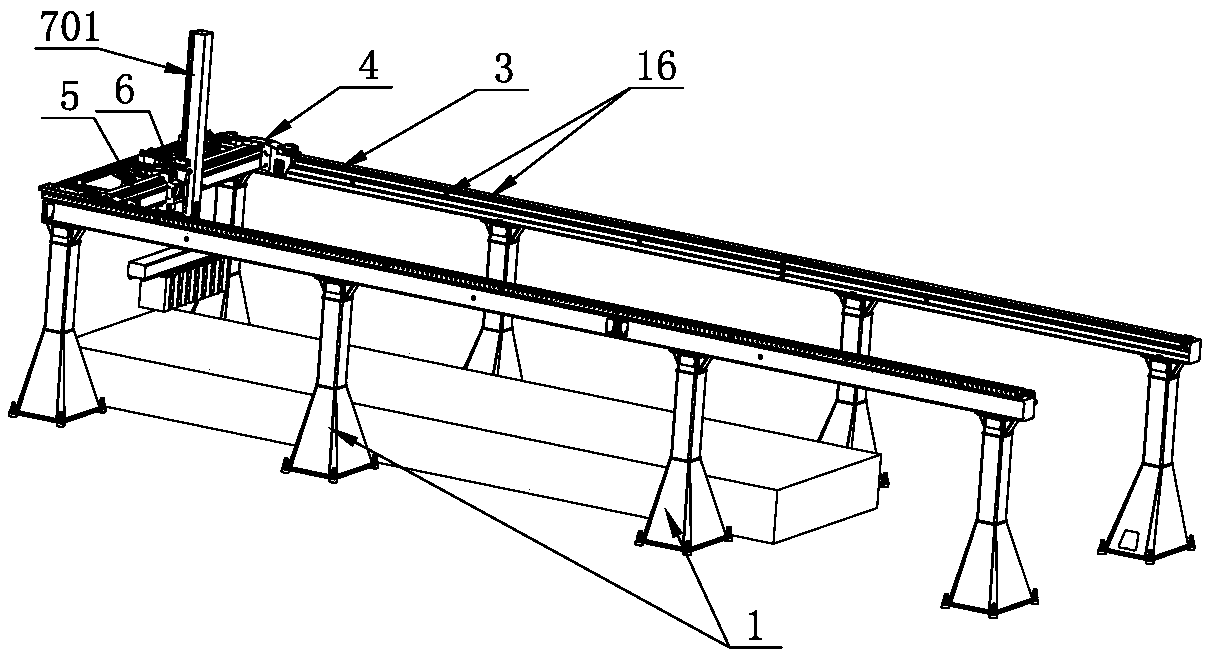

The invention discloses an apparatus and method for processing vacuum glass, which belongs to the technical field of processing. The apparatus for processing the vacuum glass comprises a transverse supporting seat I, and two transverse supporting seats II which are arranged side by side in a separating manner, wherein in a length direction, a worktable is arranged between the two transverse supporting seats, the worktable is arranged below the transverse supporting seat I, the transverse supporting seat I can move along the two transverse supporting seats, the transverse supporting seat I canmove along the two transverse supporting seats, the transverse supporting seat I is fixedly provided with a fixed seat, the fixed seat is provided with an up-down moving mechanism which can move up and down, and the bottom of the up-down moving mechanism is provided with a supporting column holding mechanism for holding a metal wire. The processing method of the vacuum glass is simplified, and theproduction efficiency is increased.

Description

technical field [0001] The invention relates to the field of processing technology, in particular to a device for processing vacuum glass and a method for processing vacuum glass using the device. Background technique [0002] It is very important to save energy and reduce consumption in buildings, cars, greenhouses and other spaces that use heating and cooling facilities. The glass windows of buildings, cars and greenhouses are the weak link of heat insulation. Compared with other insulation materials, it leads to a large energy consumption in heating and cooling facilities. In response to the above situation, people have invented a variety of energy-saving glass windows, including heat-reflecting glass windows, LOW-E glass windows, insulating glass windows and Vacuum glass windows, etc. Among them, the heat insulation efficiency of vacuum glass windows is generally better than that of other glass windows. [0003] Vacuum glass consists of two flat glasses, and there is a ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C03B23/24

CPCC03B23/245Y02P40/57Y02B80/22Y02A30/249

Inventor 奚小波许嘉文张瑞宏张翼夫张剑峰金亦富张琦

Owner YANGZHOU UNIV

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com