Method for improving large mold PVD film uniformity

A uniformity and mold technology, which is applied in the field of improving the uniformity of PVD film layers of large molds, can solve the problems of complex process and a lot of time, and achieve the effect of simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

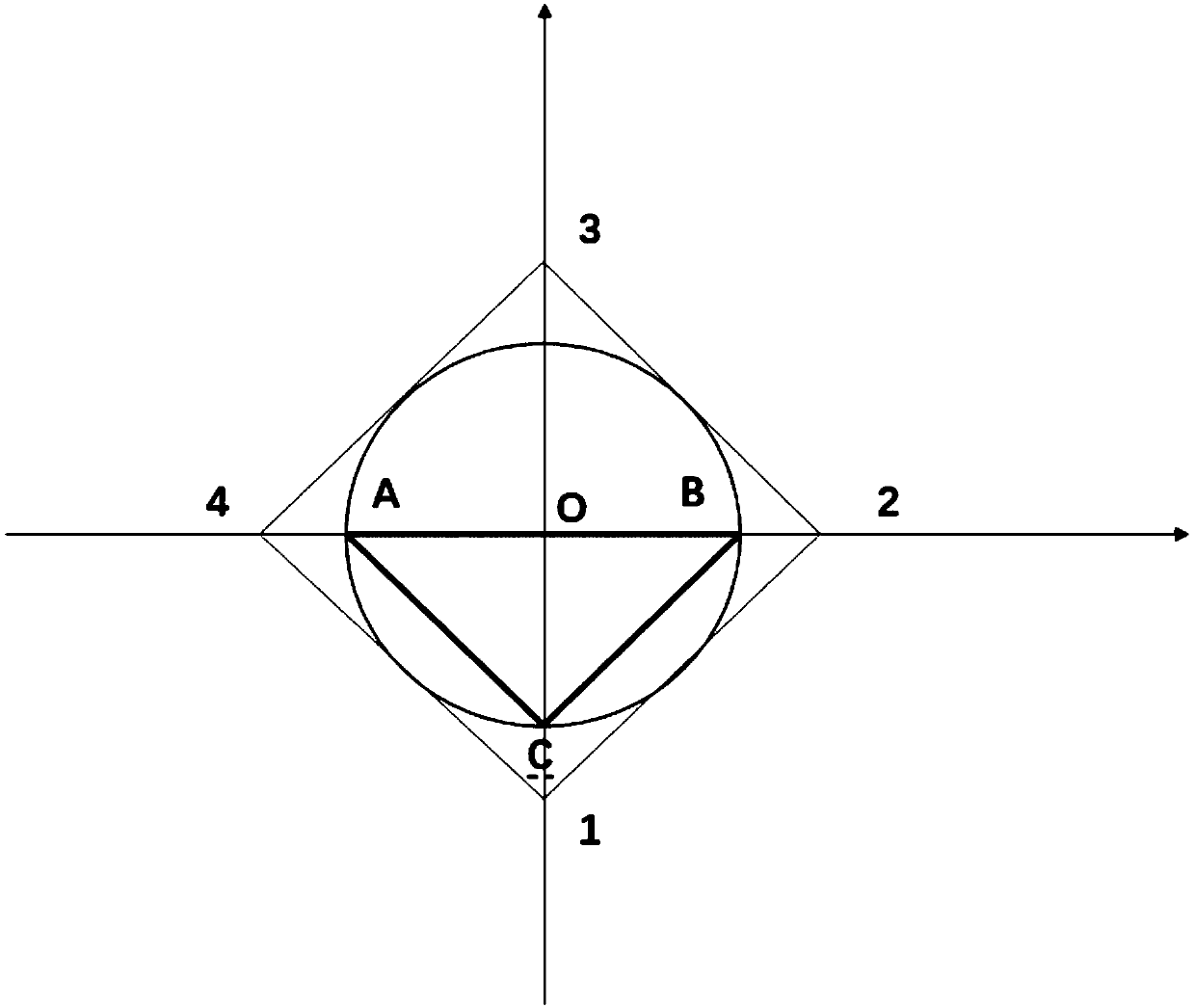

[0058] In the ABC type of the large triangular mold base, A, B and C respectively correspond to the three vertices of the triangle, and the point A of the AC surface and the midpoint O of the AB surface are selected as the design calculation of the electrical position memory uniformity, then the right angle of the triangle Edge is hypotenuse is 2;

[0059] Point A on the AC plane:

[0060] Determine the irradiation area of each target source. Under the condition of target source 1 single target, the critical situation is that the AC side and the point of target source 1 are in a straight line, and the irradiation area of target source 1 single target is calculated as (- 15°, 105°);

[0061] Further, the irradiation areas of target source 2, target source 3 and target source 4 are respectively: target source 2 (75 points, 195 points), target source 3 (165 points, 285 points), target source 4 (255 points, 155);

[0062] Overlapping regions for each target source:

[00...

Embodiment 2

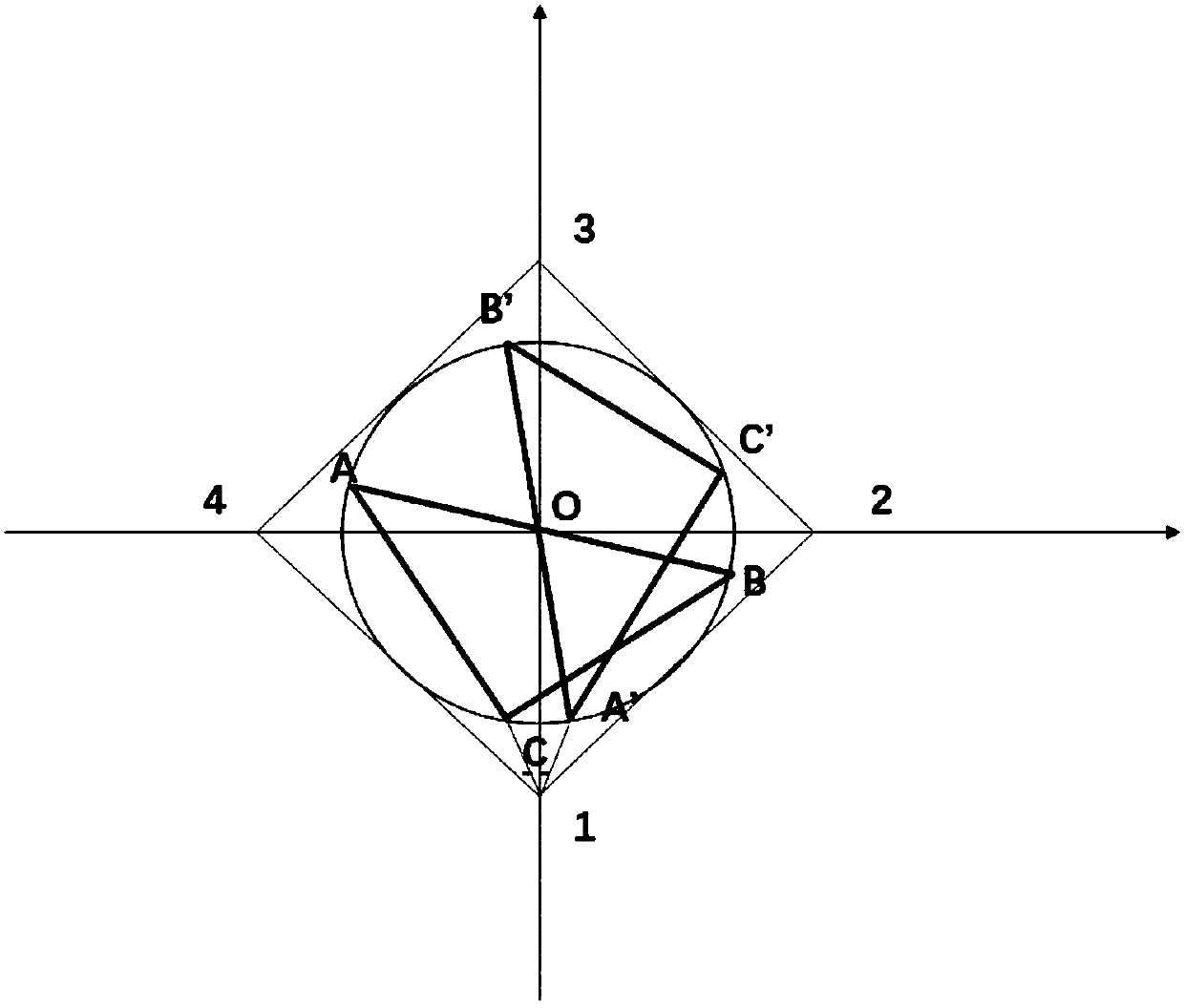

[0079] In the large-scale rectangular mold base ABCD type, A, B, C and D are used as the four vertices of the rectangle, and the length of the rectangle is wide as Select point A on the AD surface and point B on the AB surface as typical positions for uniformity calculation:

[0080] AD point A:

[0081] After determining the irradiation area of the target source, target source 1 (-60,, 600), target source 2 (300, 150,), target source 3 (120,, 240,), target source 4 (210,, 330, );

[0082] Overlapping regions for each target source:

[0083] Target source 1, 4 (-30 domain, 03);

[0084] Target source 1, 2 (300, 600);

[0085] Target source 2, 3 (120 domains, 150 domains);

[0086] Target source 3, 4 (domain 210, domain 240);

[0087] Point B on face AB:

[0088] Irradiation area of each target: target source 1 (30°, 150°), target source 2 (300°, 150°), target source 3 (120°, 240°), target source 4 (210°, 330°) ;

[0089] Overlap area:

[0090] Target 1, 4 (30°...

Embodiment 3

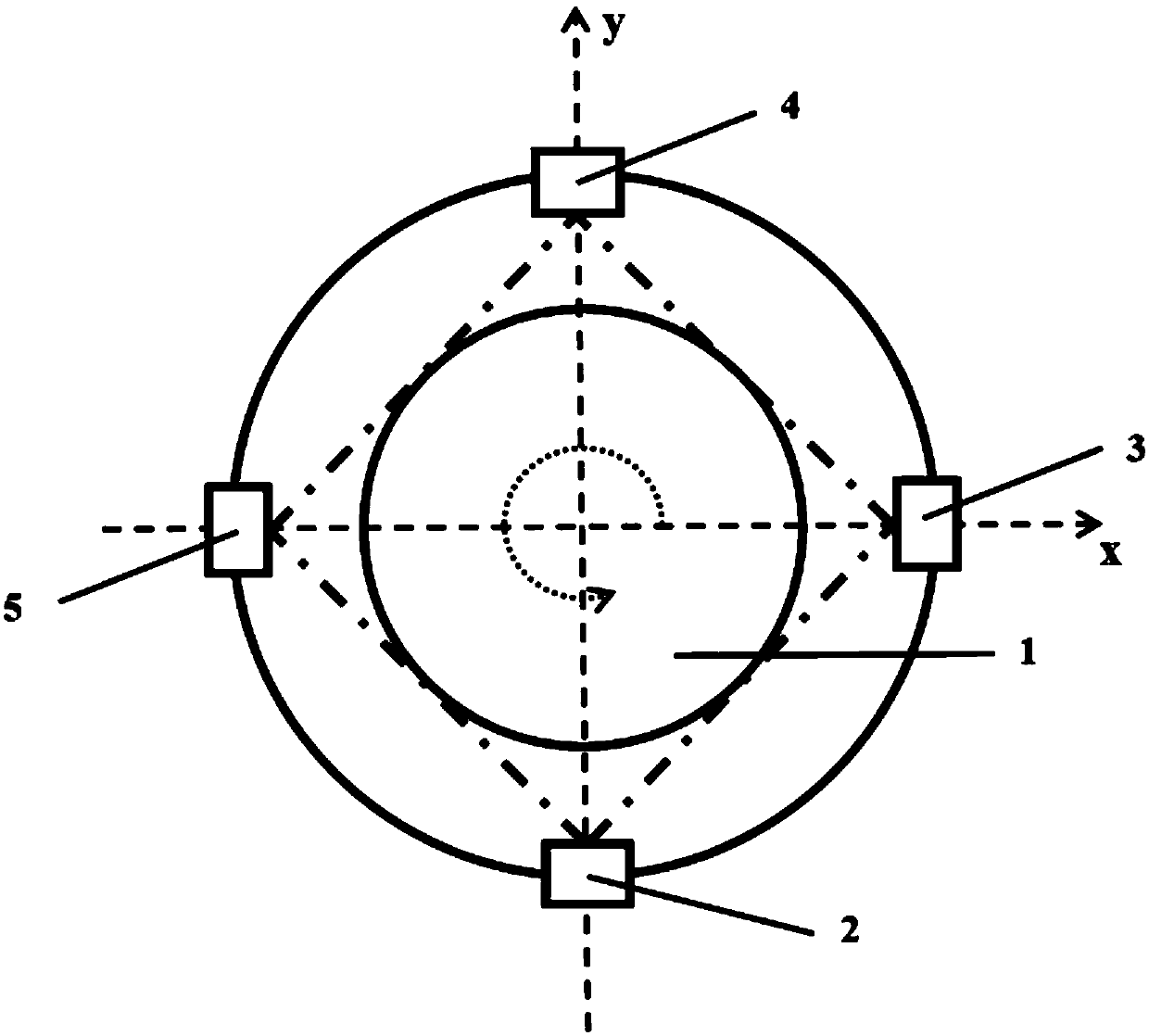

[0098] In the ABO type of large-scale arc-shaped mold base, A arc-shaped outer ring is located at the endpoint of the X-axis, B is the midpoint of the arc-shaped inner ring, and O is the center of the arc, so the radius of the outer arc is 1, and the radius of the inner arc is Select point A on the outer arc surface and point B on the inner arc surface as typical positions for uniformity calculation:

[0099] Point A on the outer arc surface:

[0100] The irradiation area of each target source: target source 1 (30:, 150 is), target source 2 (300, 150 is), target source 3 (120 is, 240 is), target source 4 (210 is, 330 is );

[0101] Overlapping regions for each target source:

[0102] Target source 1, 4 (area 30, area 60);

[0103] Target source 1, 2 (120 domains, 150 domains);

[0104] Target source 2, 3 (domain 210, domain 240);

[0105] Target source 3, 4 (300 domain, 330 domain);

[0106] Point B on the inner arc surface:

[0107] Irradiation area of each target...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com