A method for mechanically anchoring steel bars

A technology of mechanical anchoring and steel bar anchoring, which is applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of end anchorage concrete damage, welding quality is difficult to guarantee, and affect concrete pouring, etc., to shorten the length of steel anchorage and save anchorage Reinforcement, the effect of improving pouring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] All steel casings are processed by professional machinery companies. The radial dimension error of the steel casing does not exceed ±0.5mm, and the length dimension error is controlled within ±1mm.

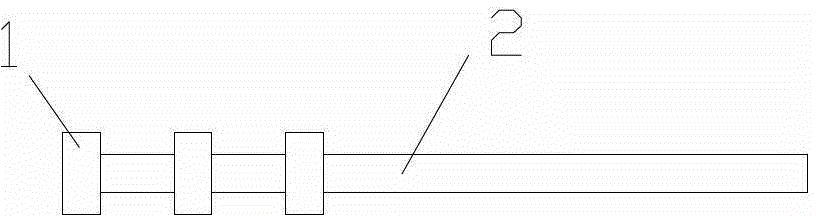

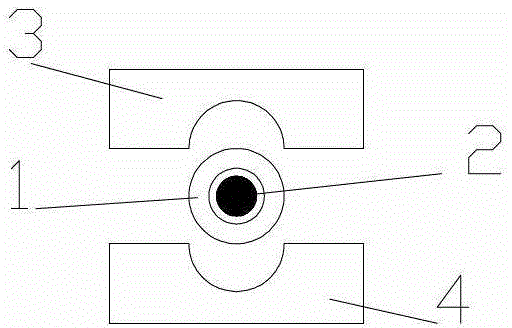

[0025] The steel casing is sleeved into the steel bar, and the radial extrusion force is applied by the high-pressure oil pump on the extrusion equipment, so that the steel casing is plastically deformed and the steel bars are tightly meshed together to complete the mechanical anchoring of the steel casing of the steel bar. Multiple steel sleeves can form multi-point anchorage to steel bars.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com