Multi-gold sheet lamination device and embroidery machine using same

A lamination device and sequin technology, applied in the direction of automatic control embroidery machines, embroidery machines, embroidery machine mechanisms, etc., can solve problems such as not easy to cut off, limited length of extension, narrow structure, etc., and achieve high embroidery efficiency , to avoid errors, and the effect of lamination is beautiful

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

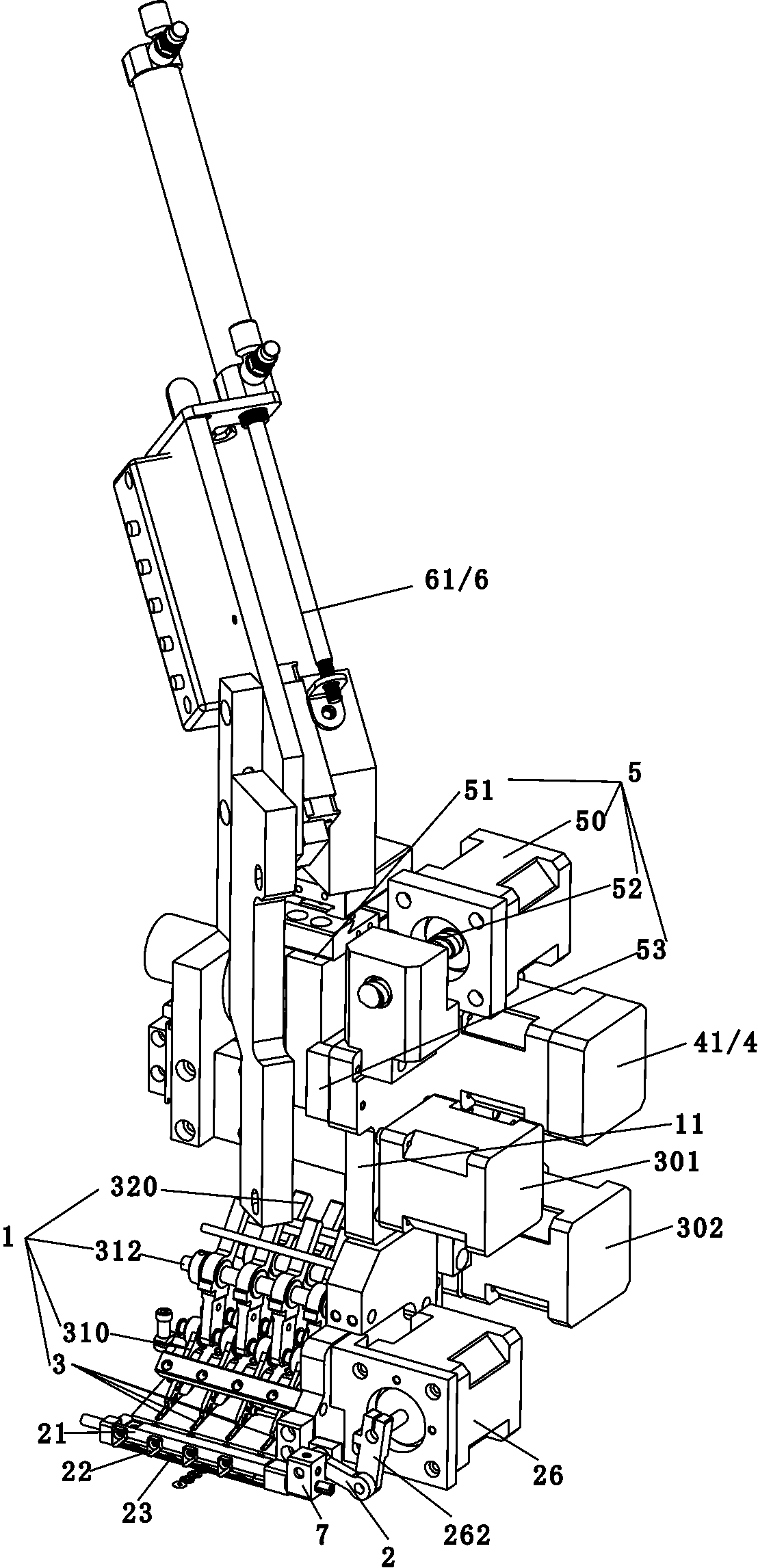

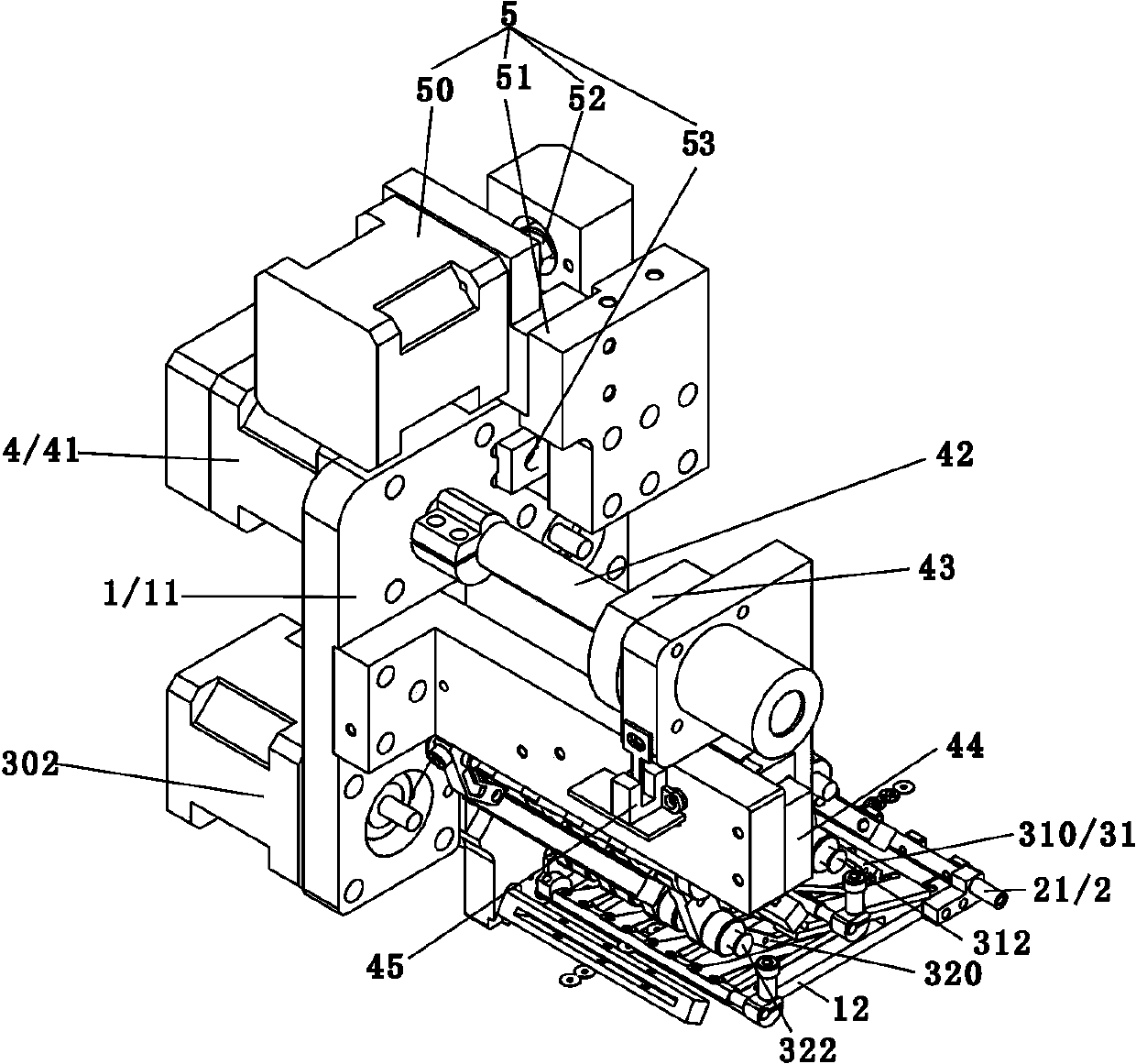

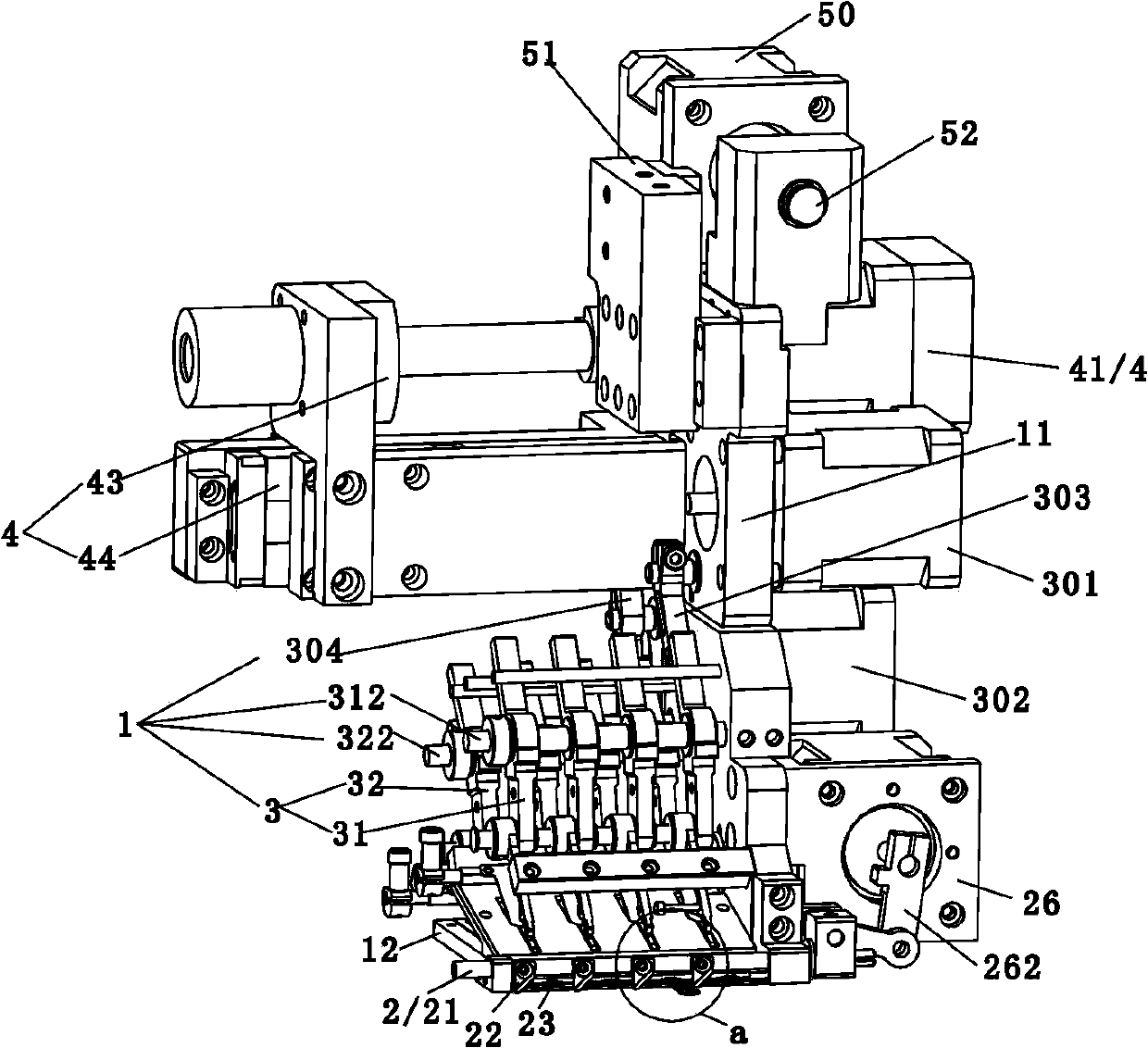

[0025] see Figure 1-8 , this implementation case includes a sheet feeding mechanism 1, a gold sheet cutting mechanism 2 matched with the sheet feeding mechanism 1, the sheet feeding mechanism 1 is provided with a mounting plate 11, at least two groups of sheet feeding devices 3 arranged side by side on the mounting plate, Drive and switch the second driver 4 and the bottom plate 12 that the corresponding group of sheet feeders 3 work to feed the sheets and cooperate with the embroidery needles. The control system can choose the control system of the existing embroidery machine, and it can be adjusted accordingly according to the needs of the action of each component. Wherein at least two groups of sheet feeders 3 include stacked upper and lower sheet feeders 31, 32, and the sheet feeding mechanism 1 is also equipped with a drive sheet feeding mechanism to feed toward the embroidery needle according to the specifications of the upper or / and lower sequins. Or move back to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com