Drainage waterproof system

A waterproof cover and flooding technology, which is applied in roof drainage, roofing, construction, etc., can solve the problems of difficult construction and short waterproofing period, and achieve the effect of long waterproofing period, reducing construction difficulty and improving drainage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

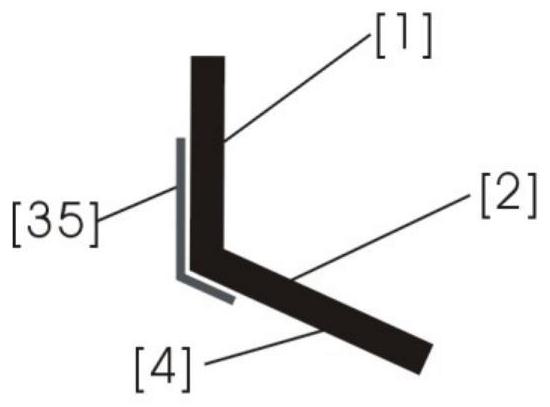

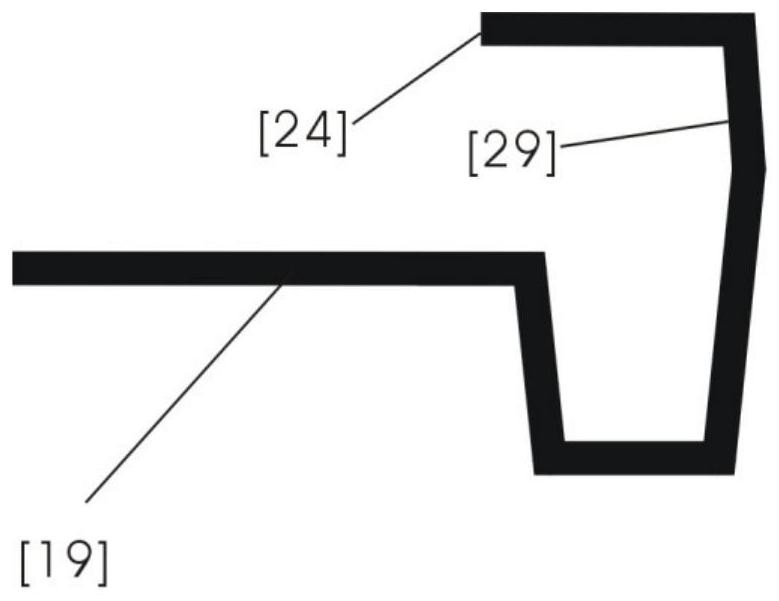

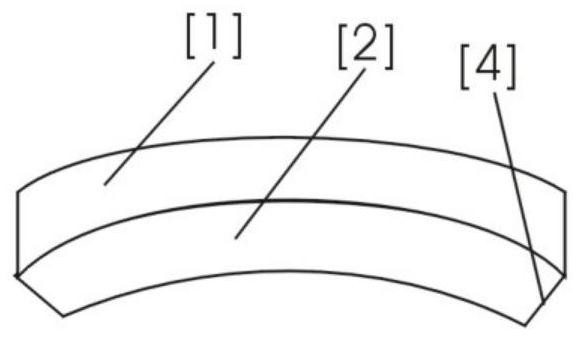

[0062] Example 1: Combining figure 1 , Figure 10 , Figure 11 , Figure 12 , Figure 18 , it is appropriate to use materials with water surface infiltration phenomenon to process the hydrophilic diversion curved surface or slope 4 with a suitable slope in the backwater surface with a half-arc shape, a half-∩ shape, a half-∧ shape, etc. as the drainage member 2, and vertically The middle and lower part of the straight sheet 1 and the upper wall outer surface of the inclined plane increase a layer of hydrophobic material layer or film as the hydrophobic surface 35, such as figure 1 As shown, it is advisable to keep a sufficient distance between the hydrophobic surface 35 and the water inlet, so as to ensure that the hydrophilic surface of the drainage member 2 has enough contact surface to drain the water flow; or the drainage member 2 processed with non-hydrophilic materials The surface of the vertical sheet 1 against the wall or the surface of the vertical sheet 1 against...

Embodiment 2

[0069] Example 2: Combining Figure 4 , Figure 7 , Figure 9 , it is on the basis of embodiment 1, and the diversion member 2 is processed into a circular diversion pan 25, such as Figure 4 As shown, the circular diversion flashing ring 25 can be used for the separation tasks of circular vertical hydrophobic surfaces such as exhaust pipes and water pipes from the water flow, reducing the construction difficulty of the waterproof layer around the circular exhaust pipes and water pipes, and improving Work efficiency; in order to improve the stability of the circular diversion flashing ring 25 on the circular exhaust pipe and the water pipe or the waterproof protection effect to the lower exhaust pipe and the water pipe, the guide of the circular diversion flashing ring 25 can be A vertical ring is processed at the end of the curved surface or inclined plane 4, and the vertical ring can be directly supported on the ground. When the sealing performance between the vertical rin...

Embodiment 3

[0071] Example 3: Binding Figure 14 , Figure 15 , Figure 16 , Figure 17 , it is installed vertically on the vertical glass curtain wall or wall such as Figure 14 Shown can prevent the water flow on the wall from flowing arbitrarily in the horizontal direction, that is, the water flow control member 14 of the hydrophilic drainage strip 13 with fibers or fabrics, etc. that have infiltration phenomenon, so that the water flow on the glass curtain wall or wall is in the direction When flowing down, it cannot cross the water flow control part 14 laterally, but can only be absorbed and guided downward by the same side of the water flow control part 14 or by the hydrophilic drainage strip 13, so as to effectively control the direction of water flow. In order to improve the drainage effect, the hydrophilic The glass curtain wall or wall surface near the water-based drainage strip 13 is processed into a hydrophobic surface or subjected to hydrophobic treatment; Both sides incr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com