Assembled shear wall structure and construction method thereof

A shear wall and prefabricated technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of poor control of construction progress, poor construction accuracy, low construction efficiency, etc., to achieve beautiful appearance, reliable quality, Fast on-site installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principles of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

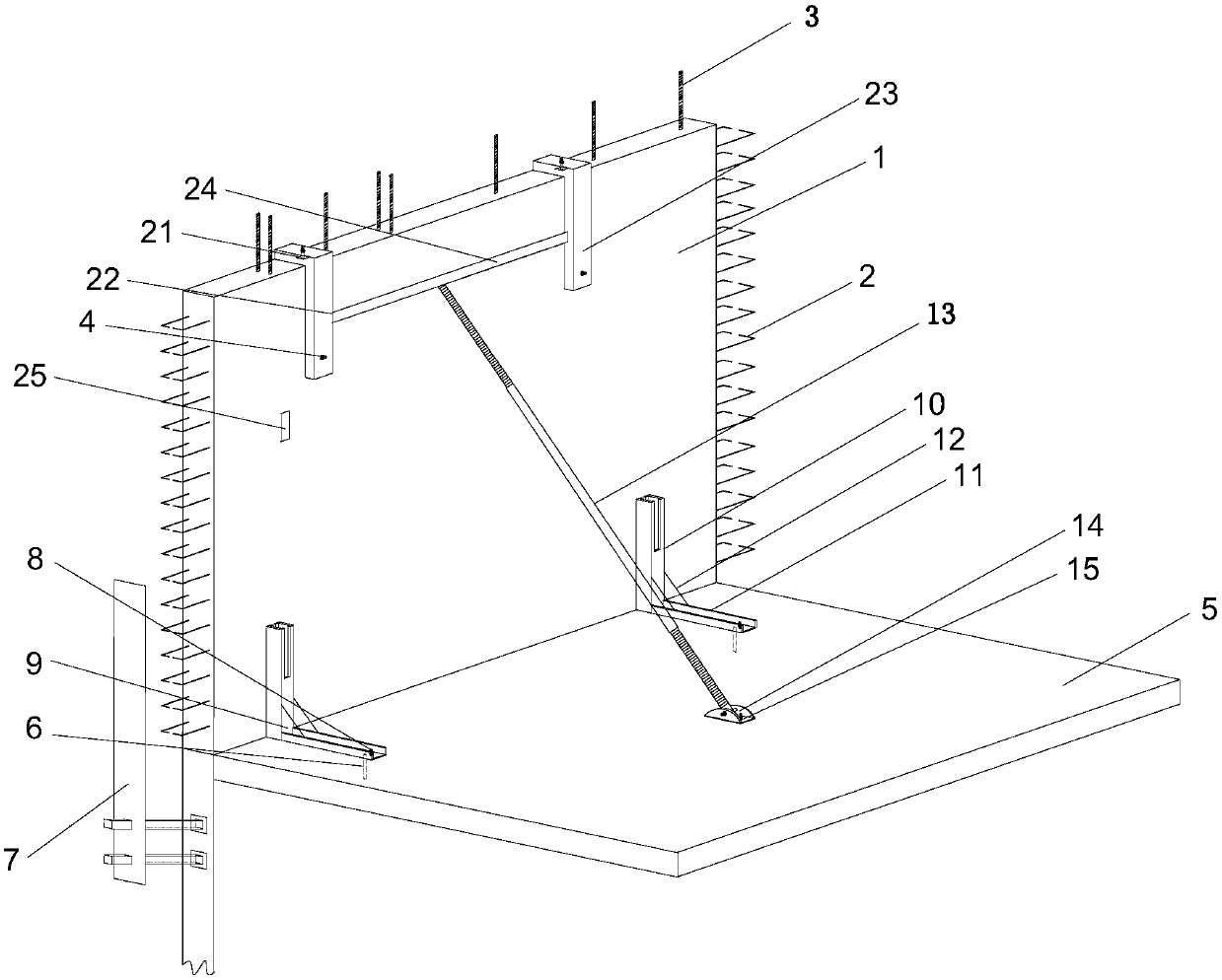

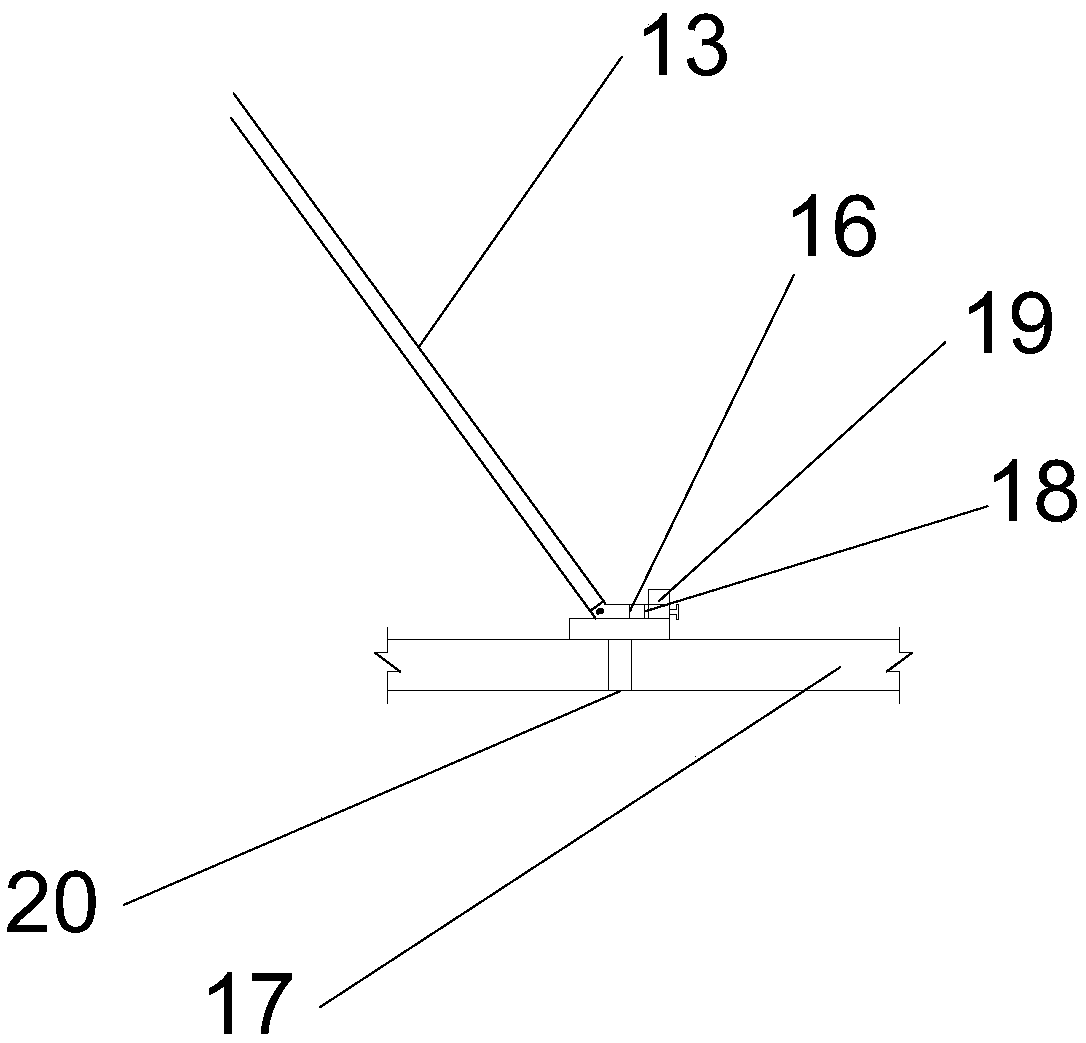

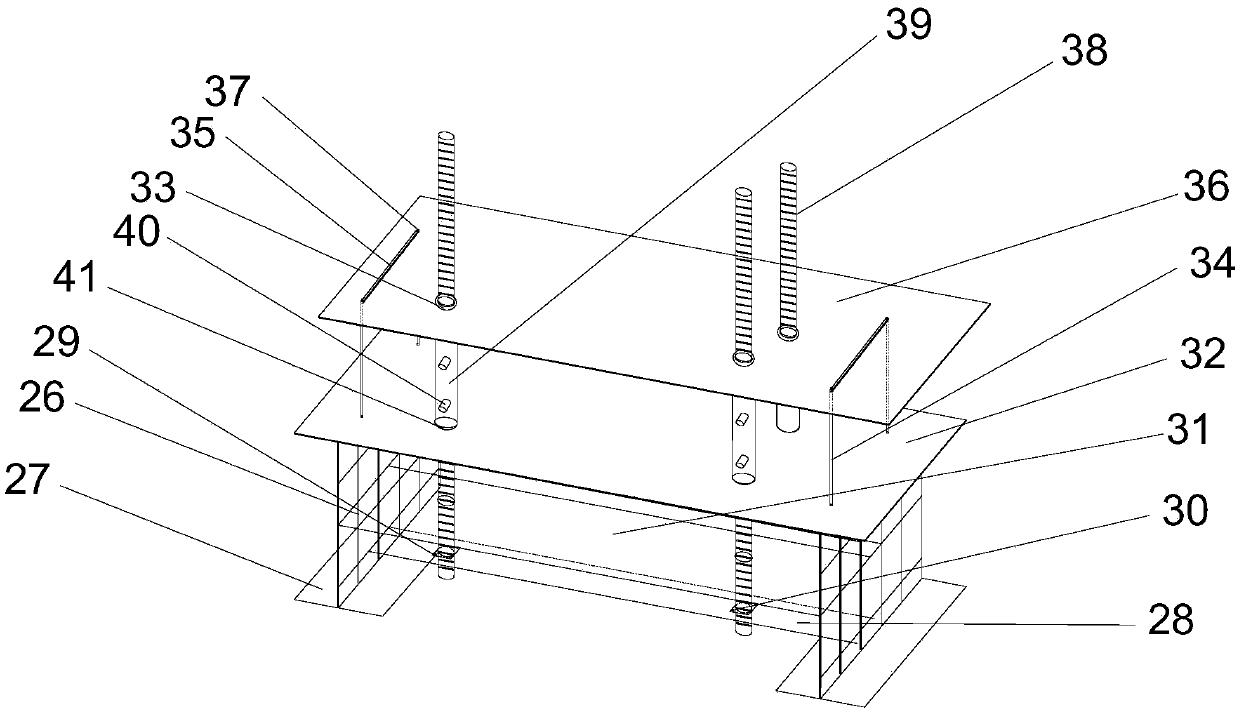

[0036] The prefabricated shear wall structure includes a prefabricated shear wall 1, reserved U-shaped ribs 2 on the side, reserved vertical connecting ribs 3, floor slabs 5, integral inner quick positioning parts 9, and verticality adjustment rods 13 , Adjusting rod base 14, frame bracket 26, suspended steel bar shelving strip 28, upper cladding plate 36, upper prefabricated wall 42, lower cast-in-place wall 43, steel bar positioning steel plate 52, prefabricate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com