A safety shoe side row assembly sewing template tooling and sewing method

A technology of safety shoes and components, which is applied in the direction of sewing equipment, sewing machine components, textiles and papermaking, etc. It can solve the problems that the side row component 1 cannot be used for sewing, and achieve the effects of improving sewing efficiency, reducing manual participation, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

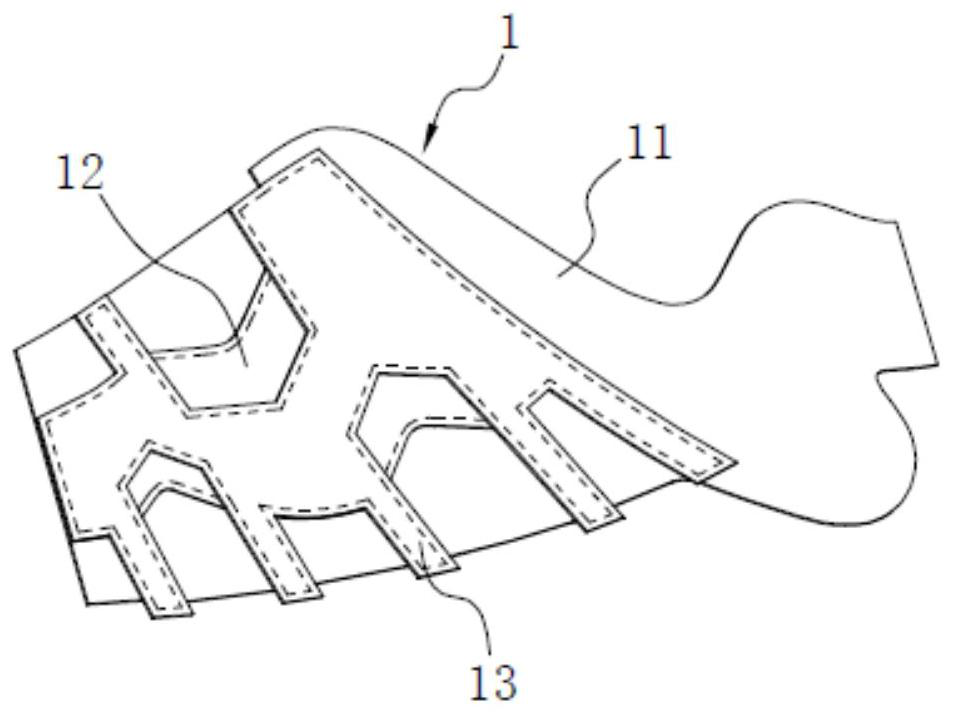

[0051] This embodiment provides a safety shoe side row assembly sewing template tooling, which is specially used for sewing the side row assemblies 1 on the left and right sides of the safety shoe body. The structures of the side row assemblies 1 on the left and right sides are symmetrical to each other. structured as figure 1 Shown in, all are made of side row base liner 11, reflective sheet 12 and side row decorative sheet 13. Refer below Figure 2 to Figure 4 As shown, the template tooling will be described in detail.

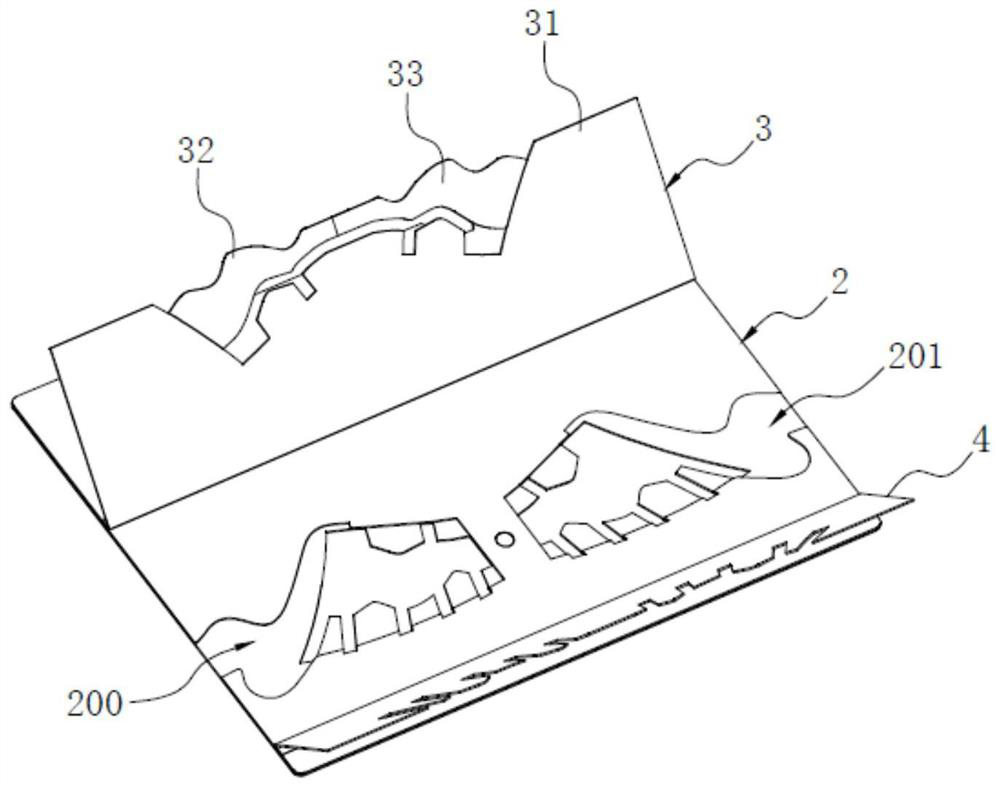

[0052] The template tooling includes a bottom plate assembly 2 , and a pressing plate assembly 3 and a fourth pressing plate 4 that cover the bottom plate assembly 2 and can be opened.

[0053] The middle part of the bottom plate assembly 2 has a first processing station 200 and a second processing station 201 with symmetrical structures, and the two processing stations are respectively used to process the side row assembly 1 on the left and right sides of...

Embodiment 2

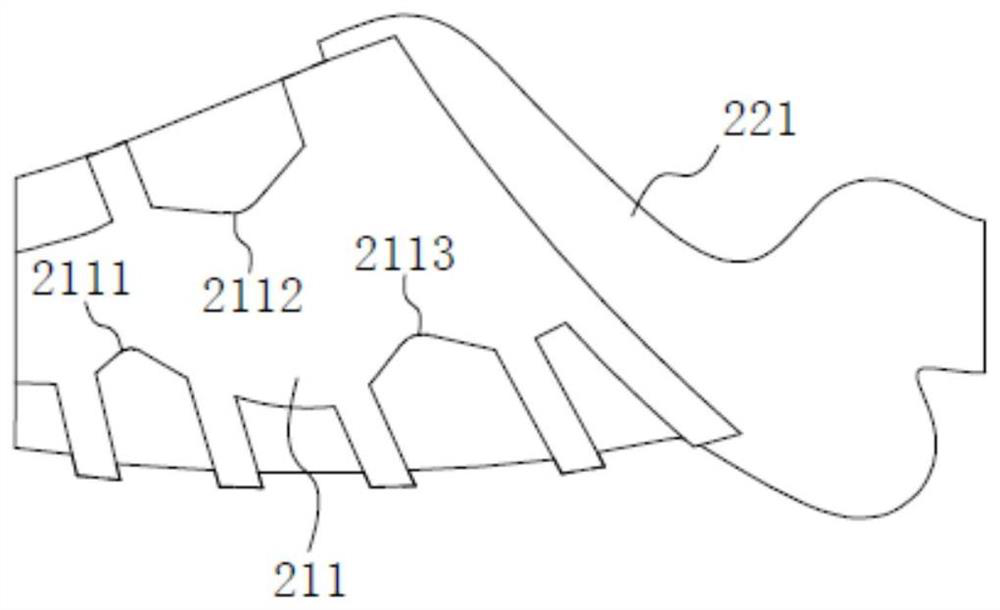

[0065] The basic structure of the sewing template tooling of the safety shoe side row assembly in this embodiment is the same as that of Embodiment 1, the differences and improvements are as follows: Figure 5 As shown in , the bottom plate assembly 2 includes a first bottom plate 21 and a second bottom plate 22 covering and fixed on the upper side of the first bottom plate 21, the trim positioning groove 211 is provided on the first bottom plate 21, the The substrate positioning groove 221 is disposed on the second bottom plate 22 . Both the trim positioning groove 211 and the lining positioning groove 221 are through grooves passing through the corresponding base plate and the lower side. In this embodiment, the first bottom plate 21 and the second bottom plate 22 are glued together.

[0066] The combination of the first base plate 21 and the second base plate 22 is used to manufacture the base plate assembly 2, only need to open corresponding positioning grooves on the cor...

Embodiment 3

[0068] The basic structure of the sewing template tooling of the safety shoe edge row assembly in this embodiment is the same as that of Embodiment 1 or 2, the differences and improvements are as follows: Figure 6 and Figure 7 As shown in , the bottom plate assembly 2 is provided with a first connecting member 23, the first connecting member 23 is located between the first processing station 200 and the second processing station 201, and the second pressing plate 32 The end opposite to the third pressing plate 33 extends to the first connecting member 23, and one of the second pressing plate 32 and the third pressing plate 33 is provided with a The second connecting member 34.

[0069] The first connecting member 23 and the second connecting member 34 are snap-connected or connected to each other by magnetic attraction. In this embodiment, the second connecting member 34 is fixed on the second pressing plate 32 , and both the first connecting member 23 and the second conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com